So after all, this has long been the custom, no matter what multi-storey building is - made of stone blocks, from panels, monolithic - this indispensable method of ascent will certainly be used in it, at least to the elevator - reinforced concrete staircase... Therefore, it should not be surprising that, despite the increased development of building technologies in recent years, such stairs account for more than 80% of all installed structures.

And hence the mass of proposals, and the mass of all kinds of options, due to the long years of production.

First high-rise buildings, and then private ownership

Hence the GOSTs, dating back to the 80s of the XX century and adopted by the "State Standard of the USSR" on the proposal of the "State Construction Committee of the USSR".

All defining GOST

The main standard, numbered 9818-85, was adopted in 1985 and is called “Marches and landings of stairs reinforced concrete. Technical conditions ".

First of all, the standard defines the types of reinforced concrete stairs.

There are three of these types:

- LM - the most common type of steps, flat without frieze steps;

- LMF - these, in contrast to the previous ones, are already ribbed and with frieze steps;

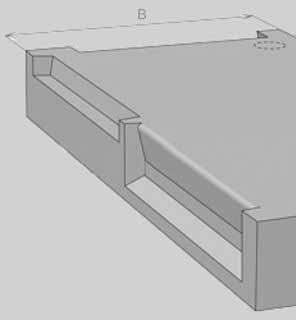

- LMP - also ribbed, but with one or two half-platforms as the upper and lower steps.

As you can see, the standard also defines two types of stair treads:

- flat - made of a single reinforced flat reinforced concrete slab;

- ribbed - two reinforced beams are already used here.

The installation of reinforced concrete stairs can also be carried out on the existing floor structure.

But GOST also defines special landings for each basic type of march:

- 1ЛП - flat platform for the march, type LM;

- 2ЛП - even though the steps of such a march are flat, it can be combined with this ribbed platform;

- LPF - ribbed platforms for LMF marches;

- BOB - also ribbed, but for LMP.

There is another classification, determined by our nature - we, after all, who are right-handed and who are left-handed. Also, the entire set of ladders is divided into right and left versions, or, in other words, for climbing clockwise and counterclockwise.

Helpful advice!

Be very attentive to the simple fact in which direction it is supposed to lift according to the existing drawing - to the right or to the left.

According to the direction, the selection of accessories for your staircase is made.

An error in this seemingly simple question will force you to lead everything back - such structures are not subject to modifications, moreover, they are categorically not allowed by GOST.

Decoding of marking

Thus, knowing the basic features of a particular type of stairs, you can decipher the nomenclature offered to you.

If you are offered a march marked LM 12/27/14-4, this means:

- at your disposal is a flat march without frieze steps - LM;

- march length in decimeters - 27, or 2 meters 70 centimeters; the length is rounded to the decimeter, thus, in reality, it can differ up or down by 10 cm;

- the width of the march in decimeters - 12, or 1 m 20 cm; here also an error of 10 cm is allowed;

- the difference in height between the two bases of the staircase, upper and lower - 14, also decimeters; this height is also called the installation height;

- the most important characteristic is the load for which the ladder is designed during the entire permissible period of its operation - 4 kiloPascals.

For the site, the decoding of marking 1LP 22.13 looks like this:

- flat platform for the LM march - 1LP;

- the width of the site, as a side perpendicular to the march, in decimeters - 22;

- length, as a side in continuation - 13, all decimeters.

All defining project

The described stairs are too serious a building material to be installed during construction without planning all the work in advance. On the contrary, the exact location of each staircase with all its characteristics is applied to the floor plan of the house with the obligatory indication of all tolerances and landings.

The stairs are installed using cranes as each floor is erected.

In this case, the following rules must be observed:

- installation work in order to comply with all safety measures must be carried out by at least 3 workers, excluding the crane operator;

- before installing the stairs, it is mandatory to install the staircase, on which the layout of the staircase is made; Needless to say, all work must be performed in strict accordance with the dimensions on the drawing - here you have to deal with structures of such weight that errors are given for correction with great additional costs;

- it is necessary to submit marches to the installation with a crane with a four-strand sling; moreover, take into account one technological feature, the two upper branches should be slightly shortened, which will give the staircase a slightly greater real slope; hence the conclusion - at first, placing the ladder on the crane, they accurately verify the location of the ladder at the bottom, and then carefully lower it onto the upper span;

- before installing the march, a cement bed is created on the support sites;

- after installation and alignment, usually with crowbars, all joints are treated again with cement mortar;

- if the staircase is based on transverse load-bearing walls, then it is recommended to use stairs of the 1LP, 2LP and LPF types;

- 1LP ladders without a supporting rib can also be installed on steel brackets pre-welded into the walls of the staircase;

- if the load-bearing walls are longitudinal at the landing, the LMP type stairs are the best option.

Classification of steps

When choosing such stairs, it is somehow not particularly customary to pick and choose and think, "why people don't fly." However, there are a few things you can think of in terms of design, in particular the shape of the steps.

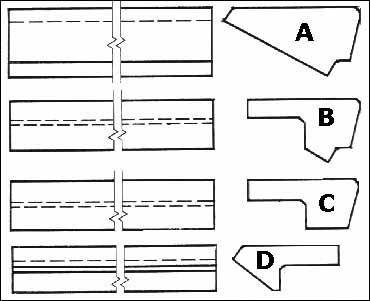

They differ as follows (see figure):

- A - stage of the LS type - the most common and cumbersome option;

- B - stage of the LSV type - here there is already a striving for the lightening of the entire structure and care for the appearance is felt;

- C - LSP-type stage - another lightweight option;

- D - stage of the LSN type - and an easy and elegant option, as far as it can be with reinforced concrete.

Weight characteristic

When it comes to reinforced concrete, the weight of the structure always comes to the fore.

We give the maximum weights of the most common brands of stairs established by the standards, and also the consumption of concrete and steel for each brand:

- LM27.11.14-4 - 1330 kg / concrete consumption - 0.53 cubic meters / steel consumption - 14.77 kg;

- LM27.12.14-4 - 1530 / 0.61 / 17.16;

- LM30.11.15-4 - 1480 / 0.59 / 16.25;

- LM30.12.15-4 - 1700 / 0.68 / 18.31;

- LMF39.12.17-5 - 1300 / 0.52 / 28.49;

- LMF42.12.18-5 - 1400 / 0.56 / 40.32;

- LMF49.14.21-5 - 1930 / 0.77 / 40.90;

- LMP57.11.14-5 - 2250 / 0.90 / 78.00;

- LMP57.11.17-5 - 2380 / 0.95 / 79.00.

Technical requirements

The seriousness of working with reinforced concrete stairs, both during installation and future long-term use, determines a whole list of technical requirements for them, including:

- requirements for the actual strength of concrete;

- requirements for frost resistance and water tightness of concrete, which is especially important for stairs installed outdoors;

- requirements for the density of lightweight concrete, GOST strictly controls excessive striving for lightweight construction;

- requirements for the abrasion of concrete - here the nature of the use of stairs "in life" already affects, and if industrial designs fully meet this requirement, then "handicraft" made reinforced concrete stairs very often do not fulfill this requirement;

- requirements for the steel grades used, by the way, for mounting hinges too;

- requirements for the thickness of the concrete layer before reinforcement;

- corrosion protection requirements.

Helpful advice!

The most important characteristic of any staircase is its load capacity, which in GOSTs is usually measured in kiloPascals (kPa). It is important to navigate in the physical value of such a value as 1 Pa.

"One Pascal" is equal to the pressure per square meter of area for 1 second of 1 kilogram.

Thus, if you have a march with a permissible load of 4 kPa at your disposal, then this means that your ladder will withstand 4 tons per square meter for no more than one second.

This is more than enough to even dance a break on the march, but keep this characteristic in mind anyway.

conclusions

Reinforced concrete structures have long invaded our lives, and it all started with stairs. Of course, you can pick up something more elegant for the interior of a country house, but in no case do not forget about this building material if you intend to build a staircase outside.

Very often you simply cannot find more reliable and more accessible material. When it comes to multi-storey construction, reinforced concrete stairs have no competitors at all.

For a visual perception of the above material, watch the video in this article!

I don’t even know why these stairs are no longer built with their own hands. my neighbor built a summer cottage and poured exactly the same sample.