What are reinforced concrete stairs? What are their dimensions? How to make a reinforced concrete staircase with your own hands? We will try to answer these and many other questions in the article.

Definitions

What is a flight of stairs? In general, this is the name of any straight section of a staircase with steps of the same size.

In our case, the definition should be somewhat specific: from the point of view of manufacturers of reinforced concrete products, staircases are elements of prefabricated staircases made of reinforced heavy or lightweight concrete that connect staircases in single-family or apartment buildings.

It is worth clarifying: a reinforced concrete staircase can be not only a prefabricated one.

Of course, pouring can also be done on site.

The only limitation is the material and, accordingly, the strength of the floors: it is clear that for wooden beams the mass of a concrete monolith is too large.

Several related terms need to be defined as well.

- Tread called the horizontal surface of the step.

- Riser - vertical, connecting treads.

- Kosour - an inclined bearing beam on which the steps are supported. In our case, the stringers for the staircase are longitudinal stiffeners that increase the bearing capacity of the march.

- Frieze step - the upper or lower step of the march. Probably, the definition should be expanded: we are talking about a step, shape or size that differs from the rest.

Questions and answers

Let's build an informative part of the article in the form of a dialogue. We will pose questions and give detailed answers to them, if possible. So let's get started.

Number of steps

How many steps can a march have?

- Their minimum number is 3. With very slight differences in height, it is easier to build a ramp or porch.

- The maximum number of steps in one march is 18. The limitation is associated not so much with the production technology or restrictions on dimensions during transportation and installation, but with the safety of moving up the stairs. In case of an accidental fall, the platform separating the marches will provide an opportunity to stop and avoid serious injuries.

Regulations

Is the production of reinforced concrete stairs regulated by any regulatory documents?

Yes. All information is contained in GOST 9818, adopted on January 1, 1986. The standard applies not only to marches, but also to overhead treads, and staircases made of reinforced concrete.

Views

What options for flights of stairs are provided by the standard?

There are three main types:

- LM - a flat flight of stairs without frieze steps.

- LMF - ribbed (with supporting beams - kosoura), equipped with frieze steps.

- LMP - ribbed with one or two half-areas.

Dimensions and weight

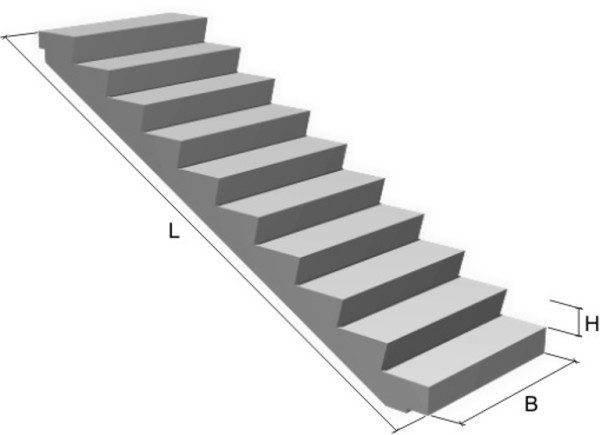

What is the height of the flight of stairs?

An important point: the height means the maximum difference between the connecting sites. The maximum longitudinal dimension of the march is called its length.

It all depends on its type.

- For LM, the height can be 1400 mm with a length of 2400 mm and 1500 with a length of 2700.

- LMFs are 1650 mm high with a length of 3000, 1800 with a length of 3300, 2100 with a length of 3900.

- LMP: 1400/2700, 1500/2700, 1650/3000, 1800/3300.

What is the vertical and horizontal step of the staircase?

- The standard tread width is 300 millimeters. However, it is not explicitly specified in the standard.

- The height of the step can take values in the range of 130 - 150 millimeters, depending on the design of the march.

It is worth clarifying: despite the absence of longer marches in the standard, they exist.

A simple multiplication of the tread width (30 cm) by the maximum number of steps in the march (18) gives us the length of the horizontal projection of the product at 5.4 meters.

What is the width of the march?

- The minimum value to be guided by when making a ladder with your own hands is stipulated by the fire safety rules. At least one interfloor staircase in any house should be no more than 900 millimeters. Otherwise, there may be congestion during the evacuation.

- LM marches can have a width of 1050 and 1200 millimeters.

- For LMF, 1200, 1350 and 1500 mm are permissible.

- All LMPs are manufactured with a width of 1150 mm.

How much concrete is used for each product?

The approximate volume of a flight of stairs of the required type can be found in the table attached to GOST.

- Concrete consumption in the production of LM - from 0.53 to 0.68 m3 per one march.

- For LMF, the range is slightly larger: from 0.52 to 0.89.

- In the production of one LMP march, from 0.73 to 1 cubic meter of concrete is consumed.

What is the weight of one march?

- LM weighs 1.33 - 1.7 tons.

- The mass of the LMF is 1.3 - 2.23 tons.

- A march of the LMP type can weigh 1.83 - 2.5 tons.

Obviously, assembling a ladder without involving heavy equipment is simply unrealistic.

Strength requirements

Is the bearing capacity of the marches regulated?

According to all the same GOST 9818, the structural elements of the stairs, without taking into account their own weight and with a strength factor of 1.2, must be designed for the following loads:

- For residential buildings - 360 kgf / m2 (3.5 kPa).

- For public and industrial buildings - 480 kgf / m2 (4.7 kPa).

Marking

What does the marking of flights of stairs mean?

Is there an instruction for decoding it?

- The first group of symbols indicates the type of march (LM, LMF or LMP) and all three of its overall dimensions (length, width and height) in decimetres rounded to whole values. For LMP with a single execution in width, it is not indicated.

- The second group contains an indication of the permissible load: 4 - for a design load of 3.5 kPa and 5 - for 4.7 kPa. If light concrete was used in the production of the march, the letter "L" is added.

- The third group is additional information. It may contain indications of the left-hand version (indicated by the letter "L"), a special type of march surface finish ("W" for a polished mosaic surface and "K" for covering with ceramic tiles). For a march of the LMP type, the number 1 denotes an elongated upper half-platform, 2 - a lower one, 3 - the absence of a lower half-platform.

Useful: the lowercase letter "c" in the third group means that the march is intended for earthquake-resistant buildings (seismicity 7-9 points).

Let's take as an example the marking of the type LM27.11.14-5-Ш.

- The first group indicates that we have a flat march with a size of 2700 (length) by 1050 (width) and 1400 (height) millimeters.

- The second is that this product is made of heavy concrete (the letter "L" is absent in the marking) and has a bearing capacity of 4.7 kPa.

- The third group contains an indication of the type of surface: mosaic polished.

Price

What is the price of marches?

It varies depending on the region, batch size and seller.

Here are a few price tags that are currently relevant for Kiev, converted into Russian currency.

- The cost of a flight of stairs LM27.11.14-4 is 4500 rubles.

- LMF39.14.17-5 costs 6,600 rubles.

- LMP57.11.18-5 - 10,000 rubles.

Installation and dismantling of stairs

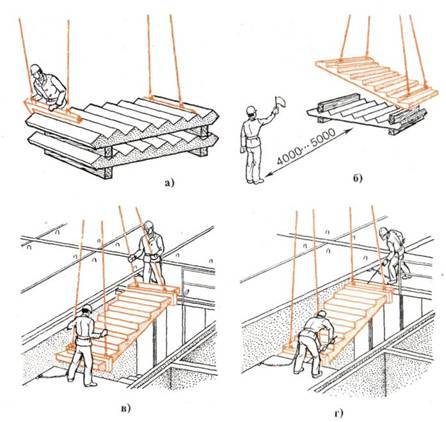

How is a massive reinforced concrete structure moved and installed? What is a staircase grab?

Moving the march is a pretty serious problem. Steel hinges for moving it are not provided for; Raising concrete is clearly a bad idea: under a load of 1-2.5 tons, slings will crash into concrete, and the likelihood that the slings will move when the march is tilted is quite high.

Climbers for stair flights are extremely strong U-shaped structures that wrap around them from the side and cannot move up or down due to the steps. The gripper starts from either side and is hooked by a spider (a branched line with four hooks) with two shortened slings, after which further movement of the ladder element presents no problems.

The actual installation is reduced to landing the march on a mortar bed - first the lower edge, then the upper one. With the simultaneous planting of the edges, the situation is quite real when the product will jam; if you land the top first, with a high probability it will simply fall off the tooth of the landing.

Correction of the position is carried out in the simplest and most affordable way - with a pair of crowbars.

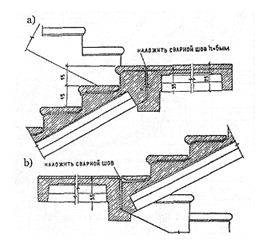

The dismantling of the staircase elements is, of course, also done with a crane. First, the upper edge is sling. It rises by 5-7 centimeters; a pair of crowbars are put under the march.

Then the bottom edge is strapped. The product rises about half a meter and is cleaned of the solution. After the slinging has been checked by workers, the structure can be moved to the storage location.

Gain

Why and how is the strengthening of flights of stairs carried out?

The goals can be pursued quite diverse:

- An increase in the bearing capacity of a structural element due to changed conditions. A typical example is the transformation of a former residential building into an administrative one.

- Partial reconstruction of a building with a long service life.

- Increase in seismic resistance of the building.

Depending on what goals are being pursued, the method of strengthening is also selected:

- Additional steel or reinforced concrete columns can be brought under the march and platforms.

- Kosoura can be reinforced with steel beams (I-beam or channel). Recently, a sticker of multilayer composite materials, including unidirectional carbon fiber, has also been used.

Reinforcement with steel beams. - Finally, the simplest reconstruction method is reduced to pouring over the steps of the stairs and platforms of a reinforced screed with a notch previously made on the concrete surface.

Monolith

How to pour a concrete staircase yourself?

What should be the formwork for staircases?

- The best formwork material is planed boards. OSB, QSB can also be used (it differs in the size of chips and the amount of resin) and plywood impregnated with linseed oil.

- The main problem is to securely fix the inclined shield, which will take on the entire mass of concrete and reinforcement. It is not enough to nail it to the side boards: you will have to build a complex structure from vertical supports.

- Before the installation of the vertical formwork elements of the steps, a reinforcing grid is laid on the shield. The distance between the reinforcement and the lower surface of the march is at least 30 millimeters. To provide a gap, the grille is laid out on spacers that are easy to bend from the wire.

- The density of the reinforcement depends on the planned load and the length of the march; in general, a mesh with a mesh of 10 cm and a wire thickness of 5-6 millimeters is sufficient.

- Used concrete grade not lower than M200. When self-preparation of the solution, 2.8 parts of sand are taken for 1 part of M400 cement. The addition of 3.8 parts of crushed stone is permissible.

Finishing

How to decorate a concrete staircase?

- The most obvious way is tiling. Clinker treads will be protected from wear for at least a century.

- The budget option is painting with alkyd enamels. On vertical and rear surfaces, PF-115 can be used, on treads - the more wear-resistant PF-266.

- Wallpaper for a flight of stairs is not a very good idea: even if only the back of the stairs is pasted over with them, the water spilled when washing the steps will leave untidy stains on them.

Output

We hope that we have answered all the reader's questions, in one way or another, affecting concrete staircases. In the video presented in this article, you will find additional information on this topic. Good luck in construction!