In each multi-storey building, both private and public, flights of stairs of various designs must be installed. They are provided even during the design of the building and are mounted as the building is being erected with the mandatory fulfillment of the requirements of GOST for flights of stairs and landings... Thanks to modern finishing materials, stairs, in addition to practical functionality, also have an aesthetic component.

Elements of reinforced concrete stairs

Reinforced concrete stairs structurally consist of several basic elements:

- reinforced concrete staircase marches;

- interfloor areas;

- overhead treads;

- fences of stepped marches.

All elements of the staircase can be made both in the left and in the right version.

Decorative finishing

If necessary, staircase elements can be made with front surface finishing and represent:

- smooth surface using heavy concrete and ordinary cement;

- polished mosaic surface of the structural decorative layer, using concrete, as well as ordinary, white, colored cement and marble crushed stone;

- surface tiled with ceramic tiles.

Long service life, relatively low price, high durability, as well as ease of installation make marching sections and platforms indispensable building elements of any multi-storey residential or office building. Moreover, such stairs are quite beautiful.

Requirements for ladder elements

According to the standard, the elements of the stairs must meet all the requirements for:

- actual strength and density of concrete;

- waterproofness;

- frost resistance;

- strength of reinforced and embedded parts;

- according to the permissible deviation of the thickness of the (protective) concrete layer to the working reinforcement;

- anti-corrosion resistance.

The main element of the staircase

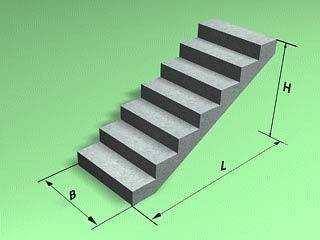

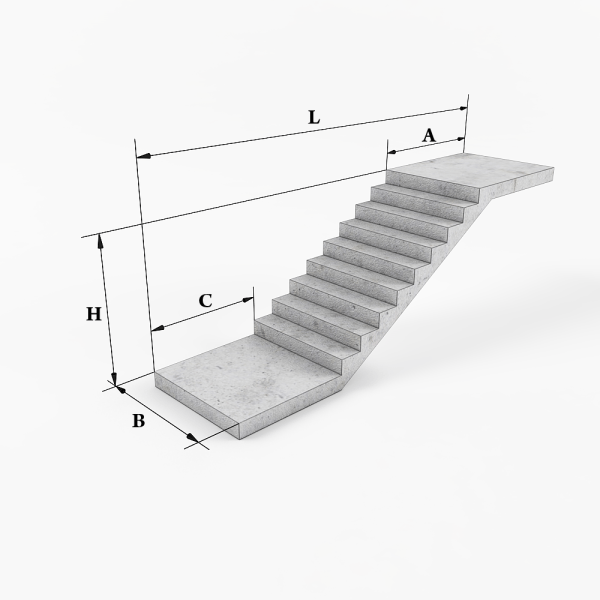

The basis of each reinforced concrete staircase is made up of flights of stairs. Structurally, they are made of load-bearing beams and rows of steps resting on them. The number of steps can be from three to eighteen.

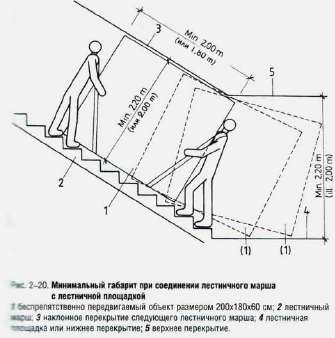

During installation, the stepped marches are connected to the interfloor areas, thus forming an integral structure.

The state standard - GOST 9818 85 for stair flights and landings applies to the step sections, as well as to all reinforced concrete products, which regulates such issues as:

- design and manufacture of different types of sections;

- basic design and coordination dimensions and parameters of products;

- requirements for the materials used, as well as their reference consumption;

- rules for the acceptance of finished products;

- control methods, as well as the procedure for testing strength and compliance of the marching sections with all requirements;

- labeling rules;

- transportation methods;

- storage rules for products.

To ensure complete safety during the long-term operation of buildings, it is necessary to comply with all drawings in accordance with GOST for flights of stairs. Departure from the requirements of the standard entails liability in accordance with applicable law.

GOST for the manufacture of stepped spans

A high margin of safety of staircase sections and increased resistance to loads, both mechanical and thermal, is achieved by using high-quality material and, first of all, by using reinforcement of a reinforced concrete structure.

For the manufacture of staircase sections used:

- heavy concrete - according to GOST 26633;

- lightweight concrete according to GOST 25820.

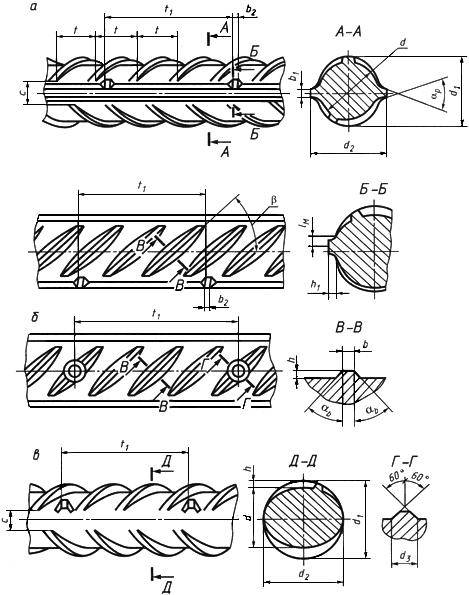

Reinforcement of stepped spans is carried out using:

- rod hot-rolled reinforcing steel (class AI-AIII) in accordance with GOST 5781;

- rod thermomechanical hardened reinforcing steel (class At-IIIС, IVС) according to GOST 10884;

- wire of class Вр-I, according to GOST 6727.

GOST on the dimensions of flights of stairs establishes requirements that relate to reinforced concrete stepped sections, interfloor areas and overhead treads, which are made using both heavy and lightweight concrete with a density from 1600 to 2000 kg / m3

All spans and platforms used for the installation of stairs are designed to operate under the following loads:

- for private (residential) structures - 360.0 kgf / sq.m;

- for industrial, public and industrial buildings - 480.0 kgf / sq.

All staircases and landings that are planned to be operated in environments characterized by an aggressive degree of impact on reinforced concrete structures are subject to the requirements of the regulatory document - SNiP 2.03.11-85.

Staircases

According to the state standard 9818 85, flights of stairs are made in several versions:

- flat, without frieze steps (LM);

- ribbed with frieze steps (LMF);

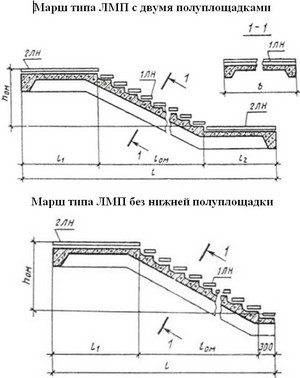

- ribbed, having half-areas (LMP). A ladder section can have two (upper and lower) half-platforms, or it can be manufactured without a lower half-platform.

Interfloor platforms

GOST for landings provides for the production of the following types:

- flat - for flat, without frieze steps, marching sections (1ЛП);

- ribbed - for flat, without frieze steps, marching sections (2ЛП);

- ribbed - for ribbed marching sections with frieze steps (LPF);

- ribbed platforms (half-platforms) for ribbed marches (BOB).

Overhead treads

It also provides for GOST for marching stairs and several types of overhead treads:

- 1LN, which are designed for stacking on ordinary and lower steps of the section;

- 2 LN, are intended for installation on the upper steps of the flight of stairs, as well as on the upper and lower platforms.

Marking of building elements

Gost to the staircase, as well as to the stepped spans, provides for a unified alphanumeric marking of architectural elements.

The first group of symbols indicates the type of stair element and its overall dimensions (length and width) expressed in decimeters. For marches, the coordination height (vertical projection) is additionally indicated.

The second group of marking symbols indicates:

- for platforms and spans - calculated live load;

- for treads - left-hand design, as well as the type and method of finishing the front upper surface.

The third group of marking symbols means:

- for platforms and spans - left-hand design, as well as the type and method of finishing the front upper surface;

- for platforms - support brackets, garbage holes, reinforced support marching nodes.

The marking of architectural elements that are intended for operation in an aggressive environment additionally contains an indicator characterizing the permeability of concrete.

Installation of stair sections

When building a country house, step spans can be installed with your own hands. The instructions below contain the main steps to ensure complete safety during the installation and further operation of the steps.

Preparatory work

Staircase steps are installed in the staircase when building walls of the house. For this, appropriate markings are made on the walls.Before starting the installation, all dimensions of the stair elements must be verified exactly.

It is also necessary to provide for special crane equipment to ensure the installation of the step sections.

Installation work

- At the first stage of installation in the staircase of the house, a layer of mortar is applied to the supporting places, then an intermediate platform with the first stepped section is installed;

- It is imperative that before the solution hardens, it is necessary to carefully verify the accuracy of the installation of the first element using horizontal and vertical levels. Before the mortar sets, the sections are amenable to adjustment;

Advice! Sections of steps must be transported and stored in stacks in a strictly horizontal position, always with steps up. Only in this order is the integrity of the structures guaranteed.

- Then it is necessary to check the installation of the first section with the project documentation. If it turns out that the top of the intermediate site turned out to be higher than the design mark, then it is necessary to raise the floor level, despite the fact that these works are associated with additional financial waste;

- The next section of steps must be fed with a special tap. The grip can be done using a sturdy four-branch sling. In this case, two branches are made shortened to give the section the necessary slope;

- The steps must first be rested against the lower platform and only then the emphasis should be placed on the upper platform. Otherwise, there is a very high probability of march failure;

- Before installing the section of steps, it is necessary to apply the required amount of mortar to the supporting places, which is carefully leveled;

- To ensure the safe installation of the steps, a minimum of three workers must be involved. One installer is on the lower platform. He accepts the section and controls the stop of the steps in the slab, correcting its position if necessary. A second installer at the top platform will ensure that the stair spans are accurately fixed to the top platform;

Output

Staircase elements manufactured and installed in strict accordance with the state standard guarantee their long-term and safe operation. When properly finished, stepped sections will brighten the interior of any building. In the video presented in this article, you will find additional information on this topic (read also GOST on fire escapes).