Almost no building can do without such an architectural element as a staircase, regardless of its purpose. Precast concrete stairs are fire resistant and functional in use.

They bring elements of individuality and originality into the design of the house. They do not require any additional maintenance and are durable in use.

Features of precast and monolithic concrete structures

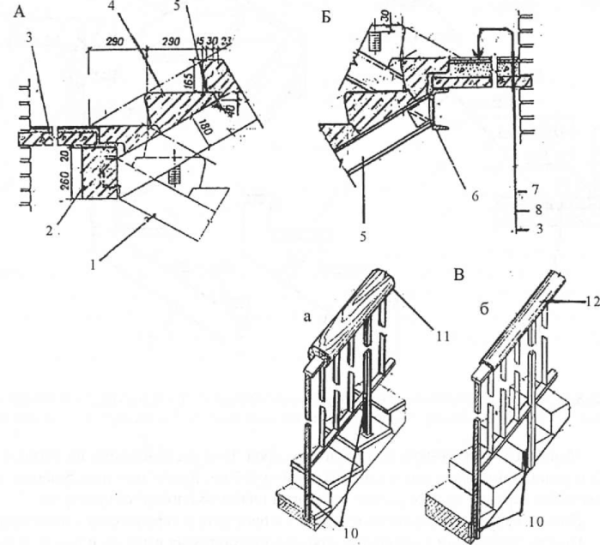

Prefabricated structures are used in buildings with transverse load-bearing walls, since reinforced concrete structures with their ends, as well as cantilever protrusions, must rest on the load-bearing walls of the building, which is called the staircase.

If there is sufficient space and equipment for lifting loads (crane equipment), the optimal solution would be a monolithic reinforced concrete staircase or steps in the form of large reinforced concrete elements. In this case, the assembly of the structure is significantly accelerated.

For private houses and cottages, developers most often prefer:

- standard (typical) reinforced concrete stairs with a slope of flights of 1 to 2;

- steeper sections that take up significantly less space. The slope of such elements is 1 in 1.75 (1.50).

The production of reinforced concrete stairs is carried out at the factories of reinforced concrete products. To ensure safety and quality control in the manufacture and installation of reinforced concrete architectural elements, GOST is provided for reinforced concrete stair steps.

All prefabricated, as well as reinforced concrete monolithic stairs, even before the start of work on the construction of the house, must be reflected in the draft floor plan.

The design documentation for the installation of steps must indicate:

- required elevation marks;

- horizontal (vertical) dimensions;

- all mounting clearances;

- dimensions of reinforced concrete steps for stairs.

Staircases

Steps are made in several versions:

- flat (LM) without frieze steps... Such stepped spans are made on a flat reinforced plate;

- ribbed (LMF) with frieze steps... In this version, the steps are made on two reinforced concrete beams, which are called kosoura;

- ribbed (LMP), having one upper half-area or two half-areas.

Flat and ribbed spans are representatives of solid reinforced concrete structures. The steps in them are cast together with the slab (kosoura).

Ribbed LMP marches are larger RC elements.

One such construct contains:

- steps;

- stringers;

- one or two half-platforms for steps.

Supports for reinforced concrete steps

Reinforced concrete staircases are also produced for each standard span of steps by precast concrete factories:

- flat 1LP - designed for flat flights of LM;

- ribbed 2LP - used with LM marches;

- ribbed LPFs, which are intended for use with LMF marches;

- ribbed BOBs for LMP marches.

All sections of steps, supports and marches are manufactured by factories, both with right and left execution, as well as with lifting for or counterclockwise.

Metal stringers

A staircase with reinforced concrete steps along metal stringers is the best option for buildings in which it is not possible to use large-size reinforced concrete structures, as well as in buildings with non-standard dimensions, built according to special projects.They are mainly used inside lobbies, as external entrances, basement marches, etc.

Such stairs can be with or without frieze steps. Fasciae give the stair supports a rectangular shape, and the upper and lower steps become part of the site. The price of such a ladder is slightly higher than the standard one.

Installation of reinforced concrete elements

When building a private house, many developers are faced with the problem of installing a reinforced concrete staircase with their own hands. To ensure complete safety during the installation and operation of the steps, it is necessary to strictly follow all the stages of installation.

Preparatory work before installation

It is necessary to install the stairs simultaneously with the construction of the walls of the house.

Advice! For the safe installation of reinforced concrete steps, at least three people are required. One installer will be on the lower floor and the other on the upper floor. The third person operates the crane equipment.

Before starting work with reinforced concrete sections and supports, it is necessary to measure their dimensions and prepare a wooden template, which will be an exact copy of the profile of the supporting part of the stepped span.

Installation work

- Places for the installation of reinforced concrete structures are marked on the walls of the staircase, a layer of cement is applied and platforms are mounted;

Advice! The installation of each slab must be checked with a wooden template and constantly checked against the construction plan. The goal is to achieve the design position of each element. Otherwise, the flight of stairs will be installed crookedly with a bias.

- Further, a cement-sand mortar is applied and leveled to the supporting places of the slabs (half-sites);

- With the help of crane equipment, sections of steps are fed for installation;

Advice! The flights must be lifted with a sling of four branches, two of which are shortened to give the section the required slope. If the stepped flights are not equipped with mounting loops, then a fork is used.

- Installers located on the lower and upper floors take the flight of stairs and control its position relative to the base plates. First, the lower and then the upper end of the march is installed in place;

Note! With the reverse sequence of installing the reinforced concrete structure (first at the top and then at the bottom), a possible breakdown of the march from the upper plate.

- If inaccuracies were made during installation, then the position of the structure can be corrected with crowbars;

- After giving march the desired position, the joints between it and the plates are closed with a solution;

- At the next stage, an inventory fence is installed;

In the video presented in this article, you will find additional information on this topic.