In the article, we will explore everything related to stair steps - their optimal dimensions, the correct names of the elements and the materials used. Can stair treads be made of agglomerate, glass or plywood? What are treads and risers? How should width and height relate?

We will try to answer all these questions.

Terminology

Let's start by getting to know the terms used by builders to designate structural elements.

- Tread is called the horizontal part of the step, on which, in fact, we put our foot when walking.

- Stair riser - a vertical element connecting two treads. It performs not only decorative, but also load-bearing functions. However, many designs do just fine without it.

- Kosour - a beam on which the steps are supported from above. Usually, there are two stringers on a straight march, but there are structures with a central location of a single load-bearing beam.

- If the steps of the stairs do not rest on the load-bearing beams from above, but in one way or another are fixed between them, a different term is used.... In this case, the beams are called ladder bowstrings.

- A flight staircase has one or more straight sections connected by landings or so-called winders with a trapezoidal tread... Each straight section is called a march.

An important point: according to the current SNiP, the march can include no more than 18 steps, and the platform connecting the marches must have a length of at least not less than the width of the stairs.

This instruction is related to safety when descending: in the event of a fall, the landing will make it possible to stop, avoiding serious injuries.

- The helical structure is assembled around the support column... The steps are the same and have the shape of a trapezoid or triangle.

- middle line - a conditional straight line or curve, which, contrary to the name, is not always drawn in the middle of a step. It is assumed that a person descending or climbing the stairs will move along it. For triangular or trapezoidal treads, the midline runs closer to the wider edge.

- Railings - a set of balusters (vertical posts) and handrails. In addition to providing safety, in some structures, handrails are part of the supporting structure. For example, at spiral staircases, the outer edges of the steps are often connected by elongated balusters: this is exactly the structure we see in the previous photo.

- Balustrade - fencing of the staircase or the inner balcony.

Dimensions (edit)

Of course, most of the parameters are selected in each case individually. And the distance between the slabs, and the size of the opening, and the requirements for compactness can vary greatly.

However, there are some optimal sizes and proportions dictated by human anatomy; in addition, a number of requirements for internal staircases are dictated by fire safety rules.

Let's look at the problem from both sides.

Convenience

Please note: the above parameters are tied to a person's height (more precisely, the length of his legs).

For a very tall or very short inhabitant of the house, the stairs of the sizes below may well seem uncomfortable.

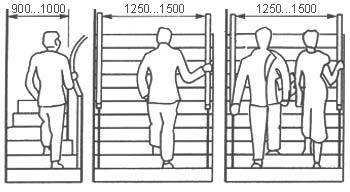

- The optimal step width for a staircase designed for the ascent or descent of one person is 90 centimeters. If the ladder is supposed to be used by two people at the same time, it is recommended to stick to a size of 125-150 centimeters.

For attics and basements, however, it is permissible to build a ladder with a width of only 50-60 cm: for the sake of compactness in this case, you can sacrifice convenience, because it is quite rare to go up to the attic or go down to the basement.

- The optimal depth of the step of the stairs should allow you to put your entire foot on it. The heel hanging down when lifting will keep the ankle muscles in constant tension; when descending, a narrow step can lead to the fact that you will find yourself at the bottom of the march much faster than you would like.

The optimal tread is 30 cm; a range of 260 - 355 mm is permissible. The exception is, again, attic and basement ladders. - The vertical step of the steps of the stairs should, on the one hand, not force the knee to be raised too wide when climbing and not create problems when descending; on the other hand, in conjunction with the depth of the tread, it allows one to overcome one step in one step.

There are two rules here:

-

- The height of the riser must be at least 15 and no more than 20 cm.

- The width of the tread and twice the height of the riser should be equal to the length of the middle step (usually 60-64 centimeters). So, with a tread width of 30 cm, the optimal height is (64-30) / 2 = 17 centimeters.

- The slope of the stairs, which makes it the most comfortable, is 1: 2 (30 degrees to the horizon). A slope in the range of 30-45 degrees is considered convenient; at 25 degrees or less, it is recommended either to build a ramp (a kind of staircase without steps, an inclined platform), or to break the staircase into several flights with a standard slope and wide horizontal platforms.

And here the attic and basement ladders keep aloof: an angle of up to 75 degrees is considered permissible for them.

Fire safety

What should be the steps to the stairs from the point of view of fire safety?

In general, the requirements do not at all contradict the wishes for comfort already stated by us. This is quite understandable: the stairs will be safe if it is convenient to go down.

Let's still mention the main points.

- At least one staircase between the floors of the house must be 90 cm or more wide.

- Let's admit a slope of no more than 40 degrees. Evacuation in case of fire should be quick, but not head over heels.

- The steps must be of the same size along the entire staircase. Otherwise, it will be easy to stumble in a smoky room.

- The tread should protrude no more than 50 millimeters beyond the riser. In this case, there is less chance of catching on the heel when descending or stumbling when climbing.

- The staircase (primarily the first and last steps) should be brightly lit.

- The depth of a triangular or trapezoidal step on the midline should not be less than 20 centimeters. The width of the narrow side of the trapezoidal step is also regulated: at least 15 cm.

- The minimum height of handrails and balustrades for stairs no more than 6 meters high is 90 cm; over 6 meters - 100 cm. At the same time, the strength of the fences should allow them to withstand a horizontal load of 100 kgf.

Materials (edit)

What steps can be constructed from? Let's try to analyze the properties of some popular materials for their creation.

Reinforced concrete

The material is perfectly familiar to any inhabitant of an apartment building.

Excellent load-bearing capacity and durability are right there; in a private house, reinforced concrete steps are much less popular:

- The huge mass makes serious demands on the strength of the floors. Houses with floors on wooden beams fall away immediately; in the case of a monolithic or slab floor of the same reinforced concrete, a calculation of its bearing capacity is required.

- When pouring stairs on the spot, a long waiting period is rather inconvenient: concrete gains strength for about a month; you can walk up the steps no earlier than 3-4 days later.

Exterior staircases on a metal frame and entrance staircases stand apart.There, concrete steps are in demand due to their resistance to humidity and temperature changes.

Useful: in this case, concrete of a grade not lower than M200 is used.

For its self-preparation, cement M400 and sand are taken in a ratio of 1: 2.8.

The addition of 4.8 parts of crushed stone is permissible.

Outdoor and indoor concrete stairs are often covered with tiles (usually clinker tiles, which are extremely wear-resistant).

Steel

Steel stair steps are a rather dubious solution for the interior; for outdoor stairs, this material is deservedly popular.

Steel stair treads have only two major problems:

- Corrosion. Alkyd primer and enamel coating will protect the steel from it, but the surface will need to be tinted from time to time.

- Noise. The fact that you are climbing an all-steel outdoor staircase will be known not only to your family members, but also to your nearest neighbors.

What type of coating can be used?

Several options are possible:

- Inlaid tread from a bar or reinforcement.

- Cut sheet. Like the previous solution, it is good in that it will not accumulate water (and, accordingly, ice in the off-season) and slip.

- Corrugated solid sheet. The corrugation will make the surface less slippery; however, in this case, there is no escape from water and ice, and the price per square meter of such a coating (and, accordingly, the cost of steps for a staircase) will be slightly higher.

Wood

The most popular material for interior stairs is, of course, wood.

There are a lot of reasons for this:

- Wood is easily handled by hand using the simplest tools.

- The most common species - spruce, pine and larch - are more than inexpensive.

An important point: the material received directly from the sawmill needs a long drying time.

The raw step will inevitably lead.

- The connection of load-bearing elements with steps and railings also presents no problems.

- Finally, the low thermal conductivity and heat capacity of wood means that wood steps will always be warm to the touch. If you like to walk barefoot, you can not expect any discomfort in this case.

Ladders can be solid wood; in addition, wooden steps are often anchored to a steel frame or concrete base.

What breeds are preferred?

- The optimal choice of hardwoods - oak, beech, ash and maple. They have a beautiful texture, which will be emphasized by the lacquer coating of the steps of the stairs; in addition, these types of wood are strong and durable.

- Birch treads are also residually strong, but lack a pronounced texture. In addition, birch rots easily: an antiseptic treatment and a waterproof coating are required.

- Budgetary solutions - spruce, larch and pine - have already been mentioned. The steps made of their wood easily leave scratches and dents. However, a durable, wear-resistant coating for stairs (for example, polyurethane parquet varnish in 5-7 layers) completely solves the problem.

Plywood

With a width of more than 50 centimeters, plywood steps for stairs are made either with a riser, or on a steel frame from a corner or professional pipe. The fact is that plywood tends to bend under load and, worse, retain deformation.

The thickness is determined by the dimensions of the step and the presence of stiffeners:

- If a steel frame around the perimeter serves as a support for the tread, you can limit yourself to 12 millimeters.

- For fully plywood steps with an emphasis on the riser, a reasonable minimum is 18 mm.

- Steps resting on bowstrings with a width of 40 - 50 cm are best made of 22 mm plywood.

Exotic

Some materials are moderately popular due to their high cost or related problems; however, they deserve a mention.

- Tempered glass is used in combination with a steel frame or so-called bolts - metal elements that connect the ladder into a single self-supporting structure. The material looks impressive; however, the slippery surface and extreme injury hazard are not very conducive to him.

- Agglomerate (artificial stone) is strong and beautiful enough, but quite expensive. In addition, it is cold to the touch: walking barefoot on its surface is rather unpleasant.

- Natural stone as a material for steps is a prestigious rather than practical solution. Let's put it this way: if you are not going to host friendly foreign delegations, it is better to forget about it.

Output

We hope that we have given the reader a general idea of the general principles of staircase construction. In the video presented in this article, you will find additional information on this topic. Good luck in construction!

Steps made of artificial or natural stone on a metal frame look very stylish. But wide wooden staircases with carved railings are closer to me. I made just these for myself, of course they are less compact and cost more expensive, but beautiful and convenient!

Total: oak, beech or ash is needed to last longer