Before discussing the topic mentioned in the title, it would not hurt to determine what a staircase is (abbreviation LK). So, in the dictionaries, this phrase is defined as a set of vertical openings in the floors of the floors, which are used to install staircases there. Now, based on the definition given by authoritative sources, we will talk about some of the features of such structures, and also watch the video in this article.

Features of cells in buildings

Types and device

First of all, you should pay attention to the fact that staircases can be ordinary or smoke-free - these are two main types of classification

| Conventional cell constructs | Smoke-free cell structures | ||

| C1 | ... To illuminate the room, natural openings (glazed or open) are used for windows and doors in the walls of the building. Electric lighting must also be present. | H1 | The entrance is possible through the smoke-free outer zone from the side of the floor, where there are open passages. |

| L2 | To illuminate the room, natural openings (glazed or open) in the roof are used. Electric lighting must also be present | H2 | In the event of a fire, air is pressurized into the staircase with the help of forced ventilation of the room. |

| — | — | H3 | The entrance is possible through the vestibule-gate, which is available on each floor. In addition, in the event of a fire, air is pressurized from the vestibule (air pressurization can also occur continuously). |

Table of differences between staircases by their types

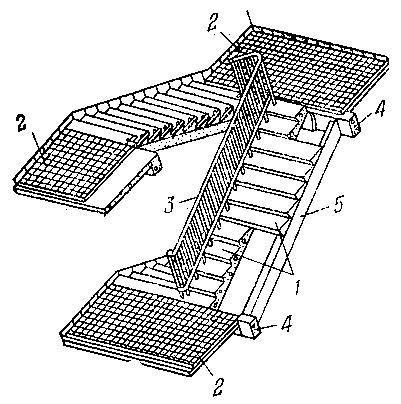

- So, first of all, let's imagine a device of the discussed structure, the construction process of which is shown in the photo above... Basically, the structure consists of four main parts, this is a load-bearing frame of columns and crossbars or load-bearing capital walls; marching stairs with steps; intermarch sites for crossings; railings or stair railings (most often made of metal). All of the above elements represent a kind of backbone, without which not a single construction of multi-storey buildings can do.

- All the load that the LM exerts on the LK is transmitted to the foundation through the walls, which also bear the load from the floors and therefore are called load-bearing... In the same way, this load can fall on the beams on which the staircases (LP) are held and the entire mass is transferred to the columns. In the photo above, you can see that the marches are additionally supported on telescopic racks, which are removed only after the concrete has gained the required brand strength.

- The concrete must set 28 days or four weeks at a temperature of at least 20⁰C for the process to complete, but there is not always time to wait... Therefore, after 3-4 days, when the concrete strength reaches 50%, they proceed to the construction of the next floor, provided that the retaining telescopic racks fully ensure the rigidity of the structure.

Recommended for private construction.

When arranging staircases and marches with your own hands in the private sector, instead of telescopic racks, boards of 150X50 mm are used, which are able to provide the rigidity of the formwork.

After 3-4 days, the flange is removed for grinding the steps, and the pallet, along with the racks, can be removed when complete solidification occurs, after four weeks.

- When designing staircases, a certain slope is set for the flights, which, when assembling the formwork, is important to maintain with an accuracy of one degree.... Otherwise, you will not be able to correctly set the design dimensions of the steps, moreover, the marches may not converge with the platforms.

- For the assembly of the formwork, in addition to telescopic racks, thick plywood and thick boards, for example, 150 × 50 mm, are used, as well as self-tapping screws, metal corners for fastening and, of course, reinforcement for the frame... Often, builders make it easier for themselves by using a "cold" seam for the junction of the march and the site, that is, one block is poured and when the solidification reaches about 30%, the next is poured.

Required condition. Before starting the casting of the formwork, it is necessary to expose the embeds for the balusters of the staircase.

They should be welded to the reinforcement cage approximately 4 steps apart, but at the corners such brackets should be present in any case.

- After four weeks, the telescopic racks and the entire pallet structure are removed - then the ladder is ready for use... But one should not forget that all floors are not poured in one day, so you need to either be equal in terms of the last pouring, or dismantle the formwork in stages. During construction, it is important not to forget that the temperature on the staircase when it solidifies should be at least 20 ⁰C, otherwise, the time required to reach the brand strength increases.

Basic fire safety requirements

- In addition to building codes and requirements, the fire safety of staircases must be observed, that is, this is a state when the flammability limits of marches and platforms correspond to load-bearing walls in accordance with SNiP I-A 6-70. Stairwells are equipped with natural openings with and without glazing. It is possible to build open LMs for lobbies and public buildings up to the height of the second floor, but if the walls in the room are made of non-combustible materials and doors are installed in the corridor.

- It is forbidden to equip any pipelines for flammable gases and liquids, as well as built-in cabinets on the stairwells, with the exception of cabinets for fire and electrical equipment and communications. Pipelines at the LK are allowed only as heating of stairwells. In buildings from 28m on the territory of the LC, it is possible to arrange a garbage chute.

- It is forbidden to equip any premises (such as an office) on the territory of the LC, with the exception of a room to guard the house. Under the marches of the lowest (first, basement, basement) floor, you can equip nodes for water supply control and electrical panel boards. The air temperature in the smoke-free staircase can be maintained by hot water heating devices.

- For communication with the territory adjacent to the building, staircase doors should be equipped, where passages to the lobby and exit to the outside should be provided. The exit for structures of type Н1 is limited only by external communication, but on each floor there must be window (glazed or non-glazed) openings (with the exception of type L2). Marches and kosoura platforms are made of fire-resistant materials, but the instructions allow them to be made of wood if the height of the building does not exceed two floors.

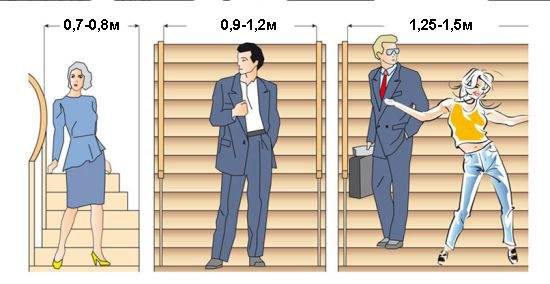

- To determine the width of the march, fire safety requirements play a key role, as well as the ability to transport any items along them. So, the minimum width of the march according to SNiP 21-01-97 * ("Fire safety of buildings and structures") will be 0.8 m, and the maximum - 2.4 m, but at the same time between the marches (U-shaped stairs) it is necessary to leave a distance of 5 cm and above for the fire hose.

- Exits to the roof from stairwells are provided in buildings higher than 10m with attics (access to the roof through the attic).In houses up to 5 floors, access to the roof from the staircase through the attic is provided through a hatch, which has at least 0.6 × 0.8 m (with a cover). A metal staircase must be attached to this hatch from the landing on the last floor.

Anti-smoke measures

- For a cage or staircase to be considered smoke-free, there must be no accumulation of smoke during a fire. For this, the fences are made of non-combustible materials (metal), and the flights, the slope of which is not more than 1: 1.5, are made of reinforced concrete. Also, to remove smoke on each floor, a walk-through door is created to communicate with the external airspace.

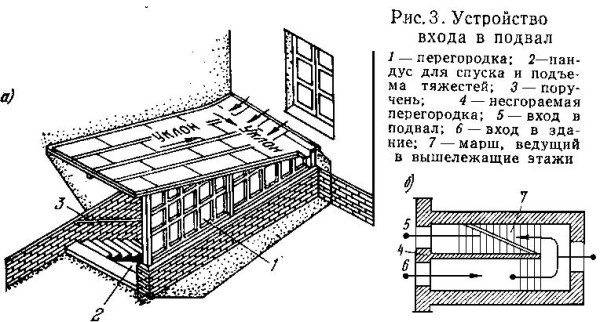

- Cages of this type provide conditions for the safe evacuation of people in case of fire, and exits there are installed directly on the street, bypassing all corridors and lobbies. But if the construction of the building does not allow creating such conditions, then the entrance is equipped through the vestibule, from where the air is pressurized. This very air pressure or forced ventilation should be carried out automatically, and for this purpose special sensors are installed that start the fan motors when there is smoke.

- For sectional residential buildings with a height of 10-16 floors with natural light, smoke hatches are provided, which are equipped either in the wall or in the roof of the LC. In such houses, transitions along balconies and loggias are provided as an emergency evacuation route, as shown in the top photo.

Advice for tenants. Balconies and loggias equipped with fire escapes, are provided for extreme, emergency cases.

When glazing loggias and balconies, some have a desire to dismantle such precautions.

Remember, the cost of not having an escape route equates to the cost of a human life!

- To ensure safety, every five years, according to NPB 245-2001 (entered into force on April 1, 2002), regardless of whether the operation was carried out or not, a regular control check of smoke-free fire ladders is carried out. Within the framework of a five-year test, bowstrings and steps are tested with a static load, which is regulated by the relevant standards. In addition, a visual inspection is carried out every year for the integrity of the welded seams and anti-corrosion coating and the quality of the bolted joints.

*Note. The + sign in the table indicates that the test should be performed, and the sign - indicates that it is not necessary.

- All tests should be carried out only by those persons and organizations that have the appropriate license and special equipment. The scope of the relevant tests is indicated in the table above and a report is drawn up in accordance with these requirements. If various cracks, ruptures and deformations are detected, after the specified loads or without them, the test is considered not passed.

- All information about malfunctions and / or damage to flights of stairs and landings that have not passed the tests must be brought to the attention of the personnel of the fire department serving the area. After the elimination of the defects revealed as a result of the check, all tests are repeated, in full.

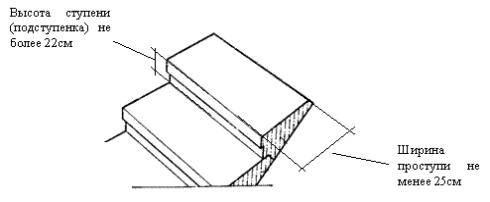

- To ensure the safety of everyday movement, and even more so, the emergency evacuation of people, it is necessary to observe certain dimensions of the steps. Thus, the step height should not exceed 220 mm, and the tread width should be at least 250 mm in order to provide 70% support for the adult's foot. The sum of the two steps height and tread width should be between 60 and 64 cm.

Conclusion

Stairwells for multi-storey residential buildings are an integral part of everyday life, which you have to deal with all the time. Therefore, their comfort and safety is on a par with the arrangement of the apartments themselves.