Outdoor stairs for a home are an important element of any building. Since almost all foundations raise the house above ground level, and there are elevation differences on the site, you cannot do without such a rise. In addition, they sometimes perform the function of an attic entrance, emergency or basement descent.

Varieties of outdoor stairs

Regardless of whether external staircases connect floors, combine landscape drops, perform auxiliary functions or are an element of an entrance group, in skillful hands they can significantly transform the exterior of a building.

However, at the same time, it is a complex design that must combine several characteristics:

- Descent and ascent safety;

- Reliability and durability;

- The convenience of use;

- Competently executed binding to the supporting structure of the building and the ground.

External stairs are distinguished, depending on their characteristics, into several types:

By form or number of marches:

- 1, 2 or 3 marching or more;

- Straight;

- Swivel.

By location:

- Profile (installed parallel to the facade);

- Frontal (located at an angle of 90 degrees relative to the facade);

- Combined (if several flights are perpendicular).

According to the shape of the landing:

- Square and rectangular;

- Round;

- Oval;

- Faceted.

Design features

Regardless of whether a modest outdoor attic staircase or a massive concrete entrance, in addition to its decorative qualities, it must comply with all technical standards.

- You can make a porch both at the same time as building a house, or attach it and then... If the main entrance to the building is made on the north side, then usually they do not make large external stairs for the porch, but build a terrace with a wide rise on the south side. Technical stairs are usually located at the end or at the back of the building, and make their design invisible.

Terrace with a comfortable rise

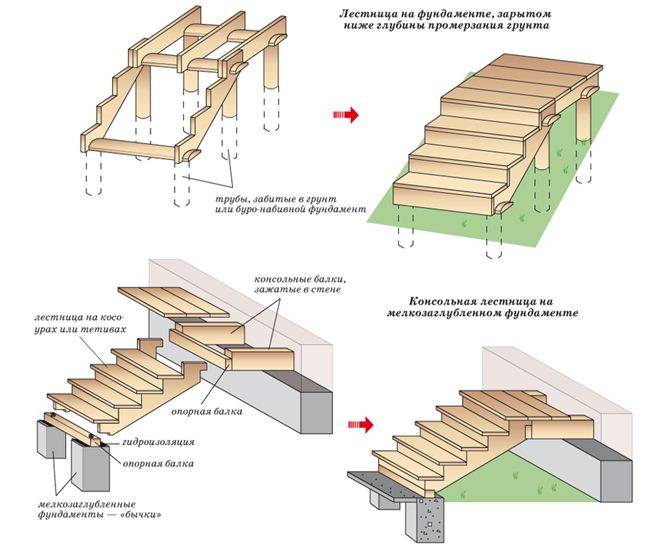

- To ensure the stability of the structure, it must be placed on a separate foundation or the base of the house.... If a few steps are enough to climb into the dwelling, then most often a monolithic porch made of reinforced concrete is poured, it will be quite stable due to its area of support on the ground.

- If you start building a lift into the house after it has been built, you may have problems due to its shrinkage.... To prevent the staircase from warping or cracking, it must be built independently. If the foundation of the house is too high, then you need to make a foundation separate from the building, which will support its edges. There should not be any anchoring to the main foundation.

- As for dimensions, external open stairs have the same requirements as internal ones: the width of the tread should be 29-33 cm, the height of the risers should be 15-17 cm, the width of the steps should be at least 80 cm... The only thing to add is 1-2 degrees of inclination of the steps of the stairs so that water does not accumulate on them. A platform should be made on top, more than half a meter wide.

- To reduce the impact of the effects of the external environment, it is recommended to make a visor or a canopy above the stairs, and make it from moisture-resistant materials.

Choosing a material

Unlike internal types, external stairs must meet a number of requirements:

- High resistance to environmental influences: high humidity, temperature drops;

- Strength;

- Durability.

Most often in individual construction, they are made of concrete, stone, brick, metal and sometimes wood.

Wooden stairs

Despite the fact that wood does not withstand a long stay outdoors, this material is quite popular for the construction of staircase structures for home and garden. First of all, this is facilitated by its low price - this is the most economical material. It is also easy and quick to handle, no special tool is required. An external staircase to the second floor of wood can be made in just a couple of hours.

A varnished wooden carved baluster can embellish any home.

For outdoor use, it is best to use dense wood species: oak, larch, wenge, bamboo. To increase their useful life, you need to treat them with an antiseptic and cover them with a waterproof varnish.

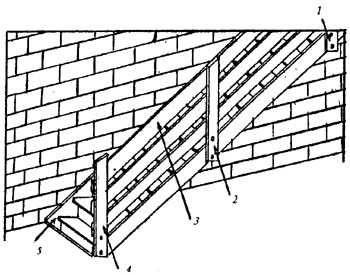

Installation of light wooden stairs is done on a columnar foundation. The pillars should be dug in below the freezing level of the soil so that they are not pushed out by the frost heave. If the installation takes place after the construction of the house, then installation on loose bulk soil should not be allowed.

It is convenient to make shallow foundations from asbestos-cement, steel pipes, immersing them in drilled wells. You can also make a base from bored piles. To protect the pipes from being squeezed out by frost heaving, they are wrapped with a layer of waterproofing and sprinkled around with sand, and the bottom of the well is made wider than the diameter of the hole.

Metal stairs

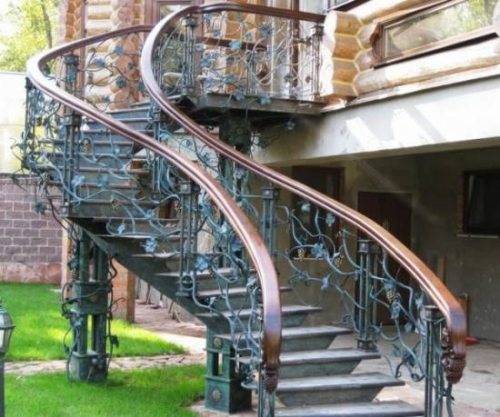

External metal stairs are equally well suited for structures for any purpose: for the front entrance, emergency exit or ascent to the second floor. Depending on the purpose, they are made of steel pipes and sheets, stainless steel, cast iron, brass decorative elements.

Outdoor staircases made of metal allow you to bring to life any design delights, and staircases can take almost any shape: straight, spiral, curved.

The parts are firmly connected by welding, and as a result, a light-looking openwork structure is obtained, but withstands a high load.

The video in this article will show you how to assemble and install an outdoor metal staircase with your own hands.

Stone stairs

This large group includes luxurious marble and granite staircases that adorn the entrances to cottages, restaurants, hotels, as well as brutal structures made of natural stone.

The cost of monolithic stone stairs is quite high, so not everyone can afford it. Their most popular construction is from concrete, cinder blocks or bricks. To save money, sometimes they use a combination of a metal frame and stone steps, or facing a concrete monolith with porcelain stoneware, clinker or floor tiles.

Brick steps

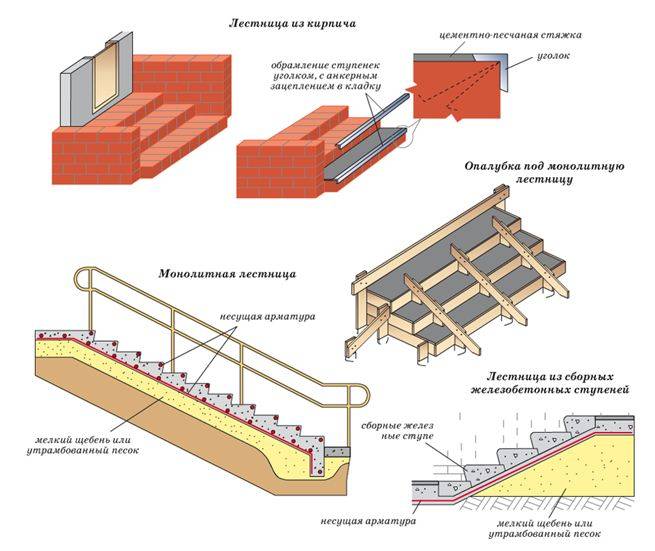

A brick staircase is certainly not the best option, but this material can be used for a small climb. Single or double hollow bricks are used, depending on the required riser height.

At the same time, keep in mind that an additional layer of mortar must be added to the height of the steps, which is usually 1 cm.Combining the position of the masonry rows, you can achieve the optimal height of the risers, which should be in the range of 12-20 cm.

The optimal tread width that is comfortable for a person should be about - 34 cm. If we add it from the nominal dimensions of a brick, then we will not be able to get it: it will be either too small or too big. The way out of this situation is simple: after laying the first step, the next rows can be slightly shifted relative to the edge of the first step, and get the width we need.

Advice!

To check if you have successfully chosen the height and width of the tread, use the formula 2 a + b = 60-64 cm, where a is the height of the riser, and b is the width of the tread.

If the result will fit within the 60 to 64 centimeters range, then the dimensions you choose will fit.

Instructions for creating brick steps consists of the following steps:

- A brick staircase is most often installed on a concrete foundation in the form of a reinforced monolithic slab. It is poured into the formwork on a sandy substrate 10 cm thick, after removing the vegetative soil layer.

- First, the first step and side walls are laid. Fine crushed stone is poured into the resulting box.

- After tamping, the second step is placed on a part of the first step and crushed stone, and the depression in the middle is also covered with crushed stone. Step by step, in this way, the entire staircase is laid out.

If you do not protect brick treads and seams from moisture, they quickly collapse. The main disadvantage of such a staircase is that the concrete screed or cladding does not hold well on the brick. To partially correct this, the corners are framed with a corner, as shown in the photo.

A concrete outdoor staircase can also be made with brick framing on the sides for beauty. In this case, the end walls are laid, crushed stone is also poured and monolithic concrete steps are poured. Or a ramp is poured, and type-setting concrete steps are attached to it.

Fencing of external stairs is usually made in the form of a massive brick wall, lattice metal railing or a balustrade. If you plan to make a metal fence, then you need to provide for this during the installation of masonry or foundation: you need to leave the embedded elements.

Overhead steps

For facing external steps, slabs made of natural or artificial stone, at least 3 cm thick, are suitable, and for risers, slabs of 2 cm or more can be used.If during the construction of the base the slope of the steps was not provided, then it should be done manually by 1-2%, with using cement mortar.

Laying should be done in such a way that an overlap of 2.5-3 cm remains on top of the riser, which will hide the joint so that the cladding looks monolithic.

To climb safely, you need to choose a non-slippery cladding material: the plates should be with a rough or corrugated texture. If, nevertheless, you decide to use smooth porcelain stoneware for finishing, then you need to provide rubber or metal nozzles with grooves at the corners, or special abrasive belts.

Conclusion

It is recommended to build external stairs to the second floor during the construction of the house, or to provide for it in advance with a single foundation with the house. If you will be installing it after installing it at home, you need to provide a floating mounting system.