Each planning, design and construction of any structures is a multi-stage process, even from the point of view of its competent and professional technological support.

Our people have a wise saying, they say, one jump at the top of the stairs will not be. So the manufacture of the stepped structure itself, which is spoken of in this folklore, consists of certain stages that must be correctly and competently overcome in accordance with GOST and SNiP in order to get not only a beautiful, but reliable and safe product in operation at the output.

A short algorithm for such a process is as follows:

- Measuring or setting the dimensions of the space of the future staircase, the place where the staircase will be located.

- The choice of building material, shape and type of stairs, fasteners.

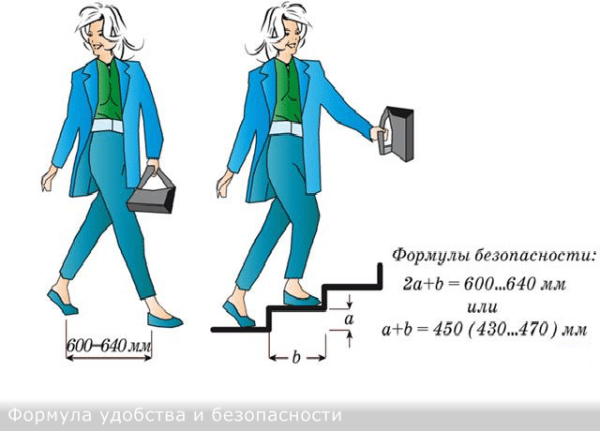

- Design and calculation of the entire staircase and its constituent elements, with drawing up spatial diagrams, sketches and drawings for production workers.

- Direct production of stairs, its elements, fencing and their installation on site.

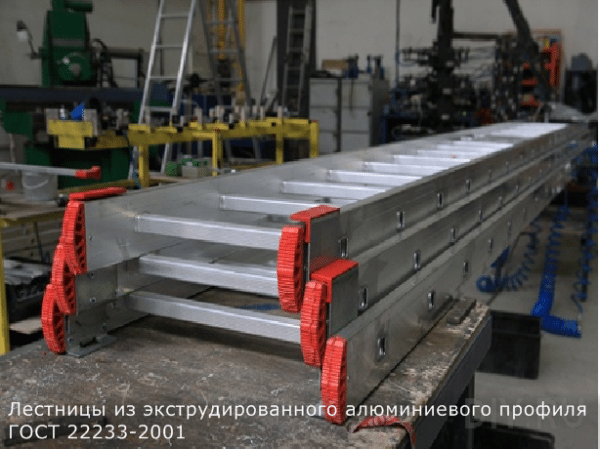

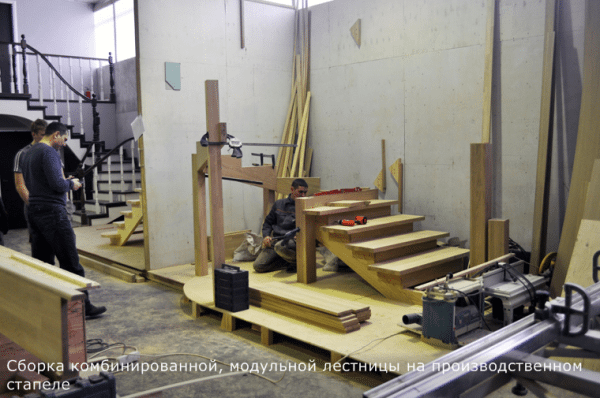

Nowadays, industrial or small-scale production and assembly of ready-made elements and ladder modules with the use of fastening points adjustable, for example, in height and direction, is gaining great popularity.

Note!

At all sites and stages of this creative and production process, first of all, one must not forget and follow the requirements and recommendations of construction documents, standards, norms and rules.

Documents you need to know and apply in the production process

So, remember that the requirements for stairs in production must comply with the current regulatory building documents.

Note!

When home craftsmen design and build similar structures with their own hands, they should also know and take into account in their activities the urgent recommendations of SNiP, GOST, NPB, because the convenience and safety of using their creations is first of all.

The difference in materials (wood, metal, glass, polymers) when creating flights of stairs and structures, in which both gluing and welding and a number of other technologies are used, implies the compliance of such a production process with the requirements of a large list of regulatory construction documents. Consider all the production of stairs, their elements and the technologies used on them, so to speak, against the background of regulatory documentation.

We list the basic building codes, rules, standards and guidelines that the production of flights of stairs, structures, their fences must comply with, with a brief announcement of their content.

Fire safety document to be observed by the manufacturer

SNiP 21 - 01 - 97 - in these norms and rules you will learn about the fire-technical terminology and classification of stairs and staircases, their fire resistance characteristics, and the main requirement for such building structures, their fences in terms of fire safety and possible evacuation along them of people.All this must be taken into account by designers, manufacturers and builders.

So that there are no problems with technical supervision of stair railings

GOST 25772 - 83 - in this state standard, read, pay attention, and most importantly apply in production practice the recommendations on the required standard sizes of steel fences of stairs and their platforms, get acquainted with their types and types (by purpose, by filling the frame) and the corresponding designations.

In the same document, you will find a table of the maximum distances between the balusters, depending on the types of steel railings. For the ultimate loads that fences must withstand, this standard advises manufacturers to refer to SNiP 2.01.07 - 85.

The production of metal stairs and railings made of metal, according to the conformity of the material for them and the rules for their welding, must be checked, as the GOST under consideration strongly recommends, respectively with SNiP II - 23 - 8 and SNiP III - 18 - 75.

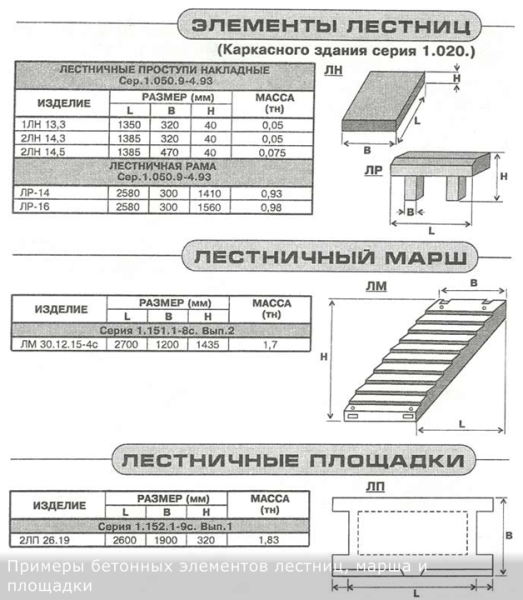

Document for the production of concrete stairs

GOST 8717.0 - 84 - provides regulatory information for the production of internal and external stairs from concrete (reinforced concrete) on a solid base.

This standard covers:

- weight characteristics (mass) and standard sizes of various types, brands of concrete (reinforced concrete) steps;

- approximate consumption of materials during their production;

- methods of their testing, control and acceptance according to the strength indicators of such concrete products.

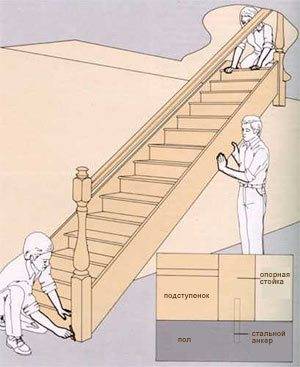

A brief instruction is given - a recommendation for fastening fences and stringers to embedded products in reinforced concrete products.

Wood coating and GOST

GOST 24404 - 80 - this standard for the finishing stage of production, when wood staircase products are covered with paints and varnishes (LKM).

It provides the following useful information for manufacturers:

- instructions for visual control of the quality of paintwork;

- tolerances and standards for coatings of classes I to V.

The GOST defines the classification of the coating of a wooden product with paintwork materials:

- by its appearance (by its optical properties - transparent, opaque, and by the degree of gloss - matte, glossy coatings);

- according to operating conditions - resistant to external climatic factors or in special environments.

Note!

There are many options for finishing industrial finishing of wooden stairs and railings with different coatings: protection - with oils, varnishes; tinting - stains, varnishes of colors; application of the firing method; artificial aging by patination; ordinary painting with paints - the choice is yours.

We glue and bend, and also according to GOST

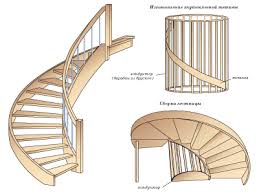

GOST 20850 - 84 - the standards of this document should be taken into account in the manufacture of glued staircase components and stairs and fences erected from bent-glued structures.

The price of a ladder made of bent-glued veneer (or solid wood) is high, its design and calculation is complicated. Although, of course, the output is very exclusive, beautiful and prestigious products.

In general, before you undertake to master such production of stairs with your own hands, you need to objectively assess your skills, experience, capabilities with your architectural and design needs and desires.Although, as Leonardo Da Vinci said: "Any obstacle is overcome by persistence."

Attention!

The production of spiral staircases and other curved structures of flights is well-established, for example, using cold-glued bending technologies, the process is very laborious, complex, requiring additional equipment (conductors), clamps and large production areas.

Norms and rules for the manufacture of wooden stairs

SNiP II - 25 - 80 - building codes and regulations for the manufacture of wooden structures, which will help in the production of wooden flights and more complex stair structures:

- find out the regulatory guidelines for the design of staircase structures made of wood, including glued and bent;

- choose the desired material from wood, based on their characteristics;

- competently and professionally to calculate the elements of stairs made of wood and their connections;

- find out in the appendices to the document the necessary initial data for the calculation.

A universal document, mandatory for all industries

SNiP 3.03.01-87 are truly universal norms, rules for all manufacturers who make different types of stairs and their fences, using various technologies.

In this construction documents, general instructions are also given that are useful when installing different types of stair structures:

- concrete and reinforced concrete (prefabricated);

- steel and wooden components;

- light fences.

Clause 8 gives general provisions for the organization of welding, which are often used in the production of metal stairs and railings. In general, a truly universal document.

Note!

If, for example, in order to save money, you are going to assemble the components of stairs and railings purchased from the manufacturer with your own hands, without having sufficient skills and experience, follow the attached assembly instructions in detail or get comprehensive advice from his representative, use only the fasteners recommended by them.

You can get more information on the topic by watching the video in this article.

conclusions

All stages and technologies for the manufacture of stairs, fences, their finishing and subsequent installation must comply with the current construction documents (GOST, SNiP).