Spiral staircases are constructions, all steps of which are winders. Sometimes such designs are the only possible solution. For example, spiral staircases to the second floor can be installed in rooms where there is no room for other types of stairs.

General information

Types of spiral staircases

There are various options for spiral staircases:

- Steps cantilever mounted on the B-pillar.

- The steps are attached to bent bowstrings and railings with bolts.

- The steps are cantilevered on the support post.

- The steps are attached simultaneously to the support post and to the walls surrounding the structure... In this case, a special well is built.

Usually, even if bent bowstrings or ladders are used, the treads are attached to the center support on one side. In doing so, they are installed radially, thus forming a screw.

Dignity

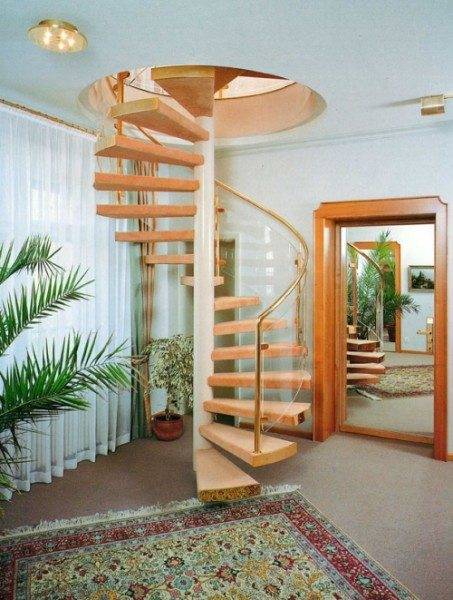

As a rule, a helical structure takes up one and a half times less space than an ordinary straight one. The radius of the circle forms the length of the tread. In addition to being compact, such designs have other advantages. In particular, they look very unusual and original, so they can become an interior decoration.

Advice!

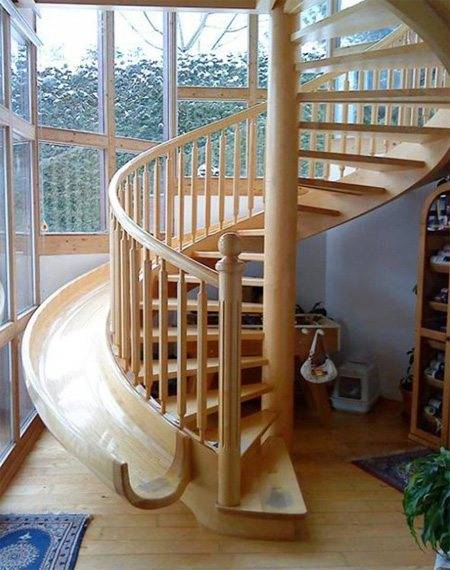

If you show creativity in the design of the structure, you can get an unexpected and very interesting result.

For example, a spiral staircase with a slide can serve not only as a means of climbing to the second floor, but also as entertainment for your child.

At the same time, the cost of a spiral staircase is much lower than that of other types of structures. Therefore, they are an excellent option for climbing the attic floor. However, along with the advantages, there are some flaws.

disadvantages

For all their beauty and compactness, such designs are not very convenient. In particular, they do not allow transporting cargo, with the exception of larger structures in which bent bowstrings are used, but in this case the occupied area is greatly increased.

Frequent spinning throughout the day can be exhausting and irritating. In addition, such stairs are quite difficult to make with your own hands.

Types of spiral staircases

With the support of steps on the console

This is the most common type of construction. The load-bearing element in this case is exclusively the central support. Most often it is a thick-walled pipe, the diameter of which must be at least 50 mm.

If you look at the product in section, it turns out that the steps for the spiral staircase and the pipe alternate. This is due to the fact that the treads on the narrow side have a hole with which they are pushed onto the post, and between them there is a sleeve made of a pipe of a thicker diameter than the post. If the steps are metal, then usually their frame is welded to the bushings.

Unlike the above designs, this one is not that difficult to do on your own. We will consider how to assemble a spiral staircase with a tread support on a console below.

Supported by handrails and bowstrings

This type of product does not have a support pillar at all. The design looks very nice and unusual, but it is extremely difficult to make it. The steps of the product are attached to the bowstrings wrapped in spirals.

It is almost impossible to make such a ladder on your own at home. This is due to the need for special equipment and experience.

With pinching of treads in the support

This type of construction is similar to the cantilever, however, the steps are inserted into the slots made in the support, rather than being put on it. Like all previous types of stairs, it does not require perimeter walls. Most often, it is based on a monolithic support post.

With the fastening of steps to the support and walls

This type of staircase requires the construction of a special well, which complicates the process of manufacturing the structure. But for that, such a product is reliable. In addition, it is possible to make long and wide steps, which makes the movement more comfortable.

Of course, in private construction it makes no sense to engage in such construction. In addition, the product will turn out to be very bulky.

Material

Spiral staircase structures are metal, wood and concrete. Each material, as usual, has its own advantages and disadvantages. Therefore, we will consider the features of each of them.

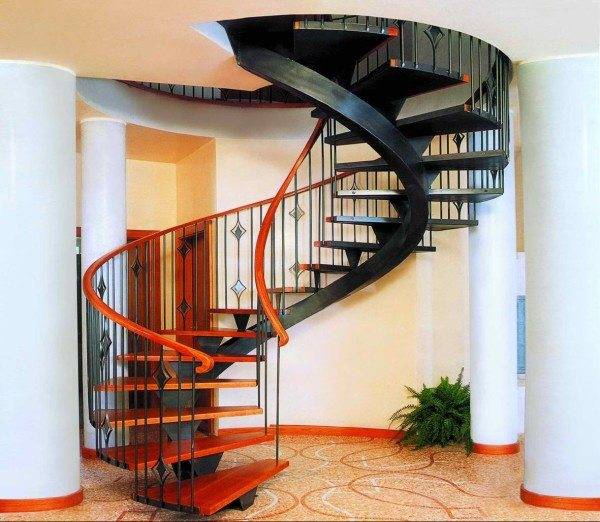

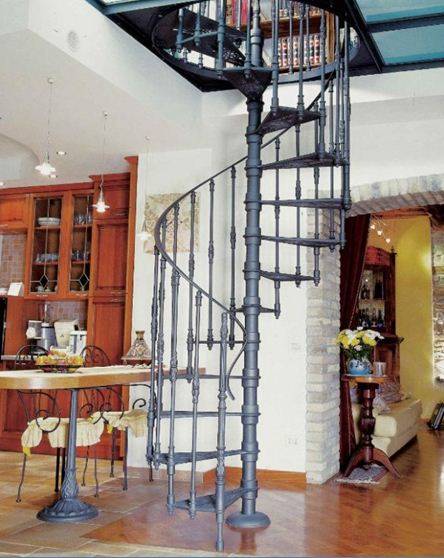

Metallic

Metal structures are quite easy to assemble, safe and comfortable enough to use. Most often, such structures have wooden treads that are attached to a metal frame.

For outdoor structures, treads are also boiled out of metal. Most often they are made from reinforcement rods.

Recently, finished metal products, especially Chinese spiral staircases, are gaining more and more popularity, since they have a low price. They are sold in a set that is assembled on site as a constructor, which is very convenient.

True, how much a spiral staircase of this type costs is rather difficult to say. It all depends on the quality of the material, as well as the size of the structure itself. Such "constructors" can be recommended to those homeowners who are not sure that they can make a staircase on their own.

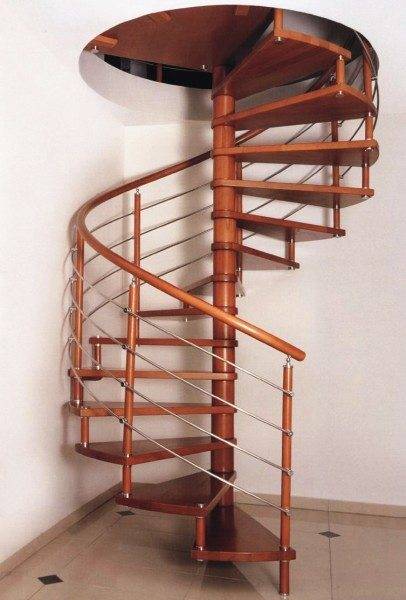

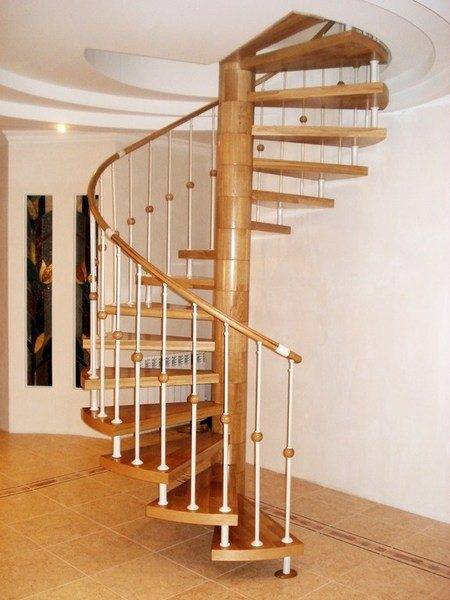

Wooden

In the manufacture of stairs from wood, only hard woods are used - beech, oak or ash. True, sometimes pine is also used, despite the fact that it is considered semi-solid. Its main advantage is its low price.

Wooden stairs are usually installed inside houses. The manufacturing principle is fully consistent with metal structures, with the exception of some fastening elements.

There is an opinion that a wooden staircase is less reliable and durable. However, if solid, high-quality wood was used in the manufacture, then the product will turn out to be very durable.

In addition, wood, as you know, is capable of imparting a special comfort to the room. Therefore, a wooden spiral staircase to the second floor can also become a natural decoration of the house.

Concrete

Monolithic concrete products have a number of advantages:

- They do not have elements that begin to loosen under the influence of dynamic loads.

- They do not make negative squeaking sounds, even if they are lined with wood on top.

- Not subject to fire.

- They allow you to embody almost any design ideas. Ladders can be either square or round-spiral. In addition, there are many options for cladding, which ensures good compatibility with other finishing materials.

At the same time, concrete structures are not too difficult to manufacture. The main question comes down to how to expose the formwork for the spiral staircase? This process is also not particularly difficult, but it requires some experience.

Advice!

To visually get rid of the bulkiness of a monolithic staircase, it can be sheathed with wood and use a neat, refined railings.

The material for the formwork is usually plywood or a thin edged board. In this case, it is necessary to use numerous supports and beams so that the formwork can support the weight of the concrete. Of course, such products have some drawbacks, first of all, they are weight and bulkiness.

The video in this article demonstrates the process of making a concrete structure.

Manufacturing and assembly of a spiral staircase

Manufacturing rules

Before proceeding with the calculation and manufacture of stairs, you must familiarize yourself with the basic norms and recommendations of specialists.This will allow you to get a comfortable and safe product.

They consist in the following points:

- It is better to refuse risers. This will allow people with large foot sizes to climb safely, and will also prevent slipping when accidentally stepping on a narrow part of the tread.

- Steps for spiral staircases on the midline of the movement must be at least 20 cm.

- The support leg must be at least 50 mm in diameter. Only in this case will the design be safe.

- The distance between the turns of the stairs should be at least two meters so that you do not have to bend over when passing over the next turn.

- Each complete turn must contain at least twelve steps.

- The length of the steps must be at least 0.8m

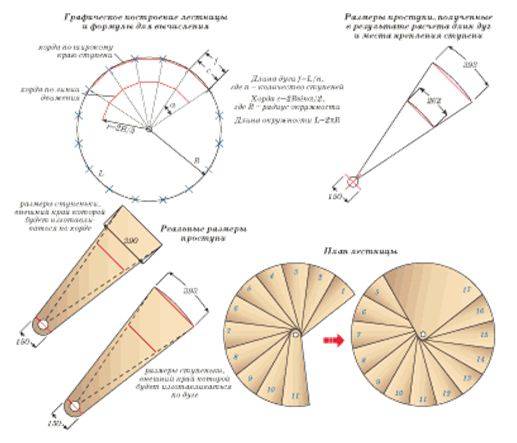

Payment

In order for the design to be convenient and safe, it is necessary to perform the calculations correctly. As an example, let's take a wooden staircase with a height of 3m, with a standard step length of 0.9m. The structure will be located on a central post with a diameter of 0.05m.

The calculation is performed in the following order:

- First of all, you need to calculate the total diameter of the product. To do this, add the two lengths of the steps and add the diameter of the rack. The result is the following calculation: 2 * 0.9 + 0.05 = 1.85m.

- Then you need to find one more value - the radius of the line of motion. To do this, add the radius of the rack to the length of the steps and divide the result by two - (0.9 + 0.05) / 2 = 0.47m.

- Next, you need to determine the number of steps per one turn. For this, we divide the circumference of the trajectory of movement by the average depth of the step: 2 * 3.14 * 0.575 / 0.2 = 18.055 ~ 18 steps.

- Now we need to determine the height of one step. To do this, divide the height of one loop by the number of steps: 2/18 = 0.11m. Now you can divide the height of the structure by the height of one step, which will allow you to find out how many steps the staircase will have: 3 / 0.11 = 27.3. Rounding off the resulting value, we get 27 steps.

Making stairs

Of course, buying a finished product and assembling it is much easier than doing everything yourself. However, the cost of spiral staircases on the market forces many to take up their own production.

In addition, the pleasure that you get when climbing a ladder made with your own hands cannot be bought for any money.

Advice!

The steps can be purchased ready-made, after which they can be adjusted to the required dimensions.

Note!

When installing, do not forget that the safety of your entire family depends on the quality of work.

Disregarding the rules can end tragically!

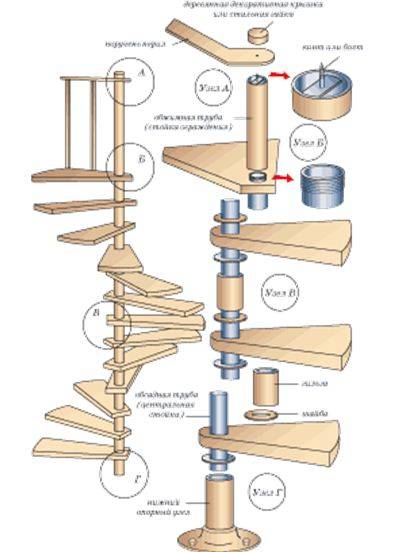

Brief manufacturing instructions are as follows:

- You can start making from the steps. The solid wood must be marked in accordance with the calculations and carefully cut out. On their narrow side, a hole should be made equal to the diameter of the rack.

- Then you need to make bushings, the length of which will correspond to the diameter of the rack.

- The rack is concreted and steps are strung on it, and bushings are installed between them.

- The steps are installed in the desired position and fastened together with racks.

- The last step is attached to the ceiling, and a decorative cover is put on the rack or a nut is screwed on.

- Then the structure is finished. There are a lot of finishing options, it all depends on your taste and the interior of the room.

Advice!

To avoid deformation of the wood at the attachment points, a wide metal washer should be placed between the bushings and the steps.

Output

Despite the fact that in many of their qualities spiral staircase structures are inferior to direct structures, in practice they have been widely used. In addition, such staircase designs allow home craftsmen to move away from typical projects and express their originality of thinking and emphasize individuality.