The time when the entrance to the attic was done separately seems to have gone forever. Indeed, it is easier to climb to the one and a half level on a convenient internal stairsThat is, even a screw, than to climb there along the attached structure, risking to look for support in the air.

Wooden stairs for home and summer cottages are the main theme of this material.

From species to techniques

The choice of wood as the main building material is not accidental, the material itself is relatively cheap, environmentally friendly, the appearance of the products (with the right approach) is incomparable with anything, it is easy to work with wood.

You can also add here that any staircase can be made from this material, judge for yourself:

- Outdoor staircase... In some houses, the ground floor level is raised relative to the ground level. For normal access, a small staircase is installed with several steps.By all the laws of the genre, a wooden frame requires a wooden staircase, although frankly, wood is a universal material and, if properly impregnated from rot, bark beetles and mold, the tree can last a very long time. A wooden veranda with carved columns can be a decoration of any home, even a stone one, even a prefabricated one using sandwich technologies;

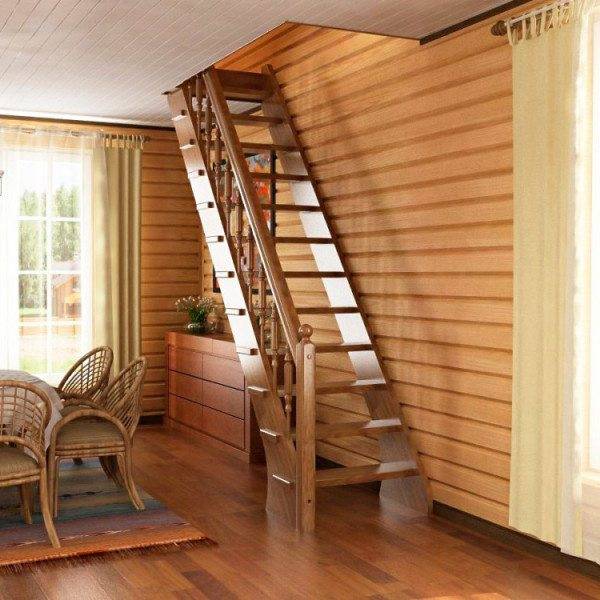

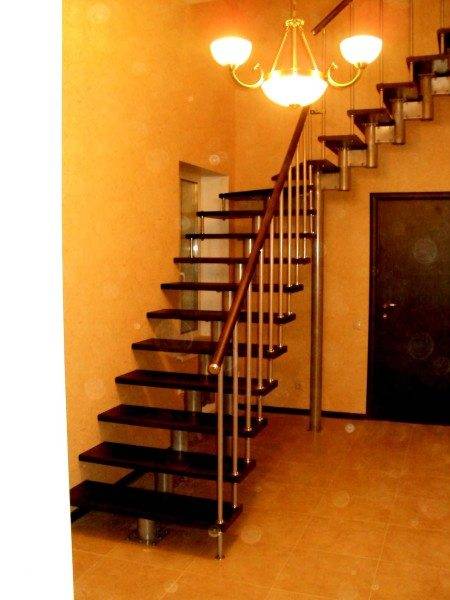

- Internal stairs... It is in the plural, since wooden stairs in private houses can have as many types as the imagination of designers and engineers is enough for. When choosing a solution, much depends on the volume of the room that you are ready to allocate for this structure, the need to use additional materials (for example, for decorating handrails or balusters), as well as the financial capabilities of the customer;

- Attached analogs... Although this view is not considered in this material, for the sake of completeness, of course, we will mention it. Let's say more, not so long ago attached wooden ladder in the house was the only option.

Interesting to know!

In some sources, you can find information that wooden stairs in the house can also be attached, while their appearance is no worse than stationary ones, except that the rise can be somewhat steeper.

Now is the time to move from species to used techniques. Currently, there are three such techniques, everything else is either their derivatives or combinations.

So:

- A wooden staircase to the house can be on kosoura;

- Wooden stairs to the house are exposed on bowstrings;

- Spiral staircase made of wood, as a separate type of product, which has its own technique of execution.

Techniques are different, principles are unshakable

The options for wooden stairs in the house may be different, but the principles by which they are designed and assembled remain unchanged: convenience, safety and aesthetic component. If aesthetics and decoration are a creative component, then safety and convenience, in this case, have a well-defined mathematical expression.

And it is measured by three parameters:

- A step is the width of the step itself, on which a person's foot is placed;

- A riser is the height of the distance between two adjacent steps from each other;

- The angle of inclination of the stairs. This parameter is calculated experimentally and hammered into the canons of ergonomics in the range from 25 to 45 degrees.

Note!

All the numerical values given by our instruction were determined experimentally and have a fairly clear scientific and practical application.

Now you can go through the numbers and get the benefit that has names: safety and convenience:

- A tread falls under the above criteria if its width is in the range from 20 to 40 cm;

- The riser also has its own comfort limits - from 12 to 20 cm;

- The angle of inclination can be primary and proceed from the existing structural features and the structure being erected, where using the banal trigonometric function of the tangent of the angle, you can determine the distance between the steps or the width of the steps themselves (the tangent of the angle will be equal to the ratio between the riser and the tread). Or it can be secondary, when the volume of the room is sufficient and allows not to save on safety and comfort of ascent and descent.

Ergonomists went even further, and calculated several acceptable options for stairs, expressing them with the same ratio of risers and treads and giving them the following definitions and numerical expressions:

- The optimal option is the ratio of 17 to 29 (all dimensions are given in cm);

- An economical solution - 19 to 22.5;

- Comfortable proportion - 13 to 32.

And in order to completely close the calculation topic, we give a few more interesting figures that can have both cognitive and practical value:

- A safe step is one in which the sum of the riser and tread is 46 cm;

- The same criteria apply for a value of 12 cm. In this case, the riser height is subtracted from the tread width;

- The size is 63 cm. These are two tread sizes and the total tread width.

These parameters can be considered control or verification, deviations from them in the design of stairs are quite acceptable.

Kosoura - special areas

A wooden staircase for a house requires serious fasteners, this applies not only to the bearing beams themselves, but also directly to the steps. In the design of these stairs, there are either one or two bearing supports, in which the cuts of the cell are prepared in the form of a ladder.

It is in these cells that future steps will be attached. This technology is as simple as it is reliable.

For your information!

Even in this technique, there are recommended parameters for the supports.

The step board should rest on prepared bases, the thickness of which is at least 100 mm, and the height of the support beams is from 100 to 150 mm.

The technological aspects of the assembly are as follows:

- In the supporting beam (s), cells are prepared in the form of a ladder, in which the steps will be installed;

- The beams are fixed permanently in such a way that the places for fastening the steps in the double-girder version are at the same level. Checking with a building level with your own hands will not be a problem;

- The steps of the stairs are installed from below and go up, with each subsequent step overlapping the inner edge of the previous one by 3-5 cm;

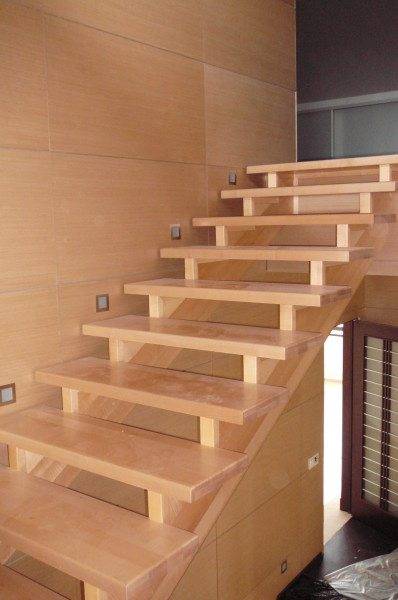

- In the absence of risers, the strength of the structure will not decrease. For lovers of air products, this option will be the most suitable. If you plan to make a niche under the stairs, then it is better to "walled up" it completely.

Bowstrings as a form of fastening

This technique is somewhat more complicated than the previous one; it requires skills and special equipment. Difficulties, albeit conditional, nevertheless exist. The fact is that in this case it is necessary to prepare a place for a step in the beam itself, and for this it is necessary not only to correctly outline the place of wood extraction, but also to choose it.

Moreover, the structure is assembled and then installed on a stationary place, in narrow places: corridors, hallways, this does not always work out. And the last difficulty lies in the fact that no matter how tight the step fits into its groove, the tree deforms over time, and this connection must be additionally fixed either with metal brackets or pins with threads at the ends and nuts.

And in all other respects, the technology is also simple:

- The supporting beam or board is sawn at the required angle and the contours of the grooves for treads and risers are drawn in the body of the material;

- With the help of tools, grooves are prepared, it is mandatory to control not only the correctness of manufacture, but also the symmetry of the grooves in two beams;

- Further, there is an external reinforcement of the bearing beams by attaching similar ones;

- Each span must be reinforced with staples or pins for one flight, 2-3 fasteners are enough.

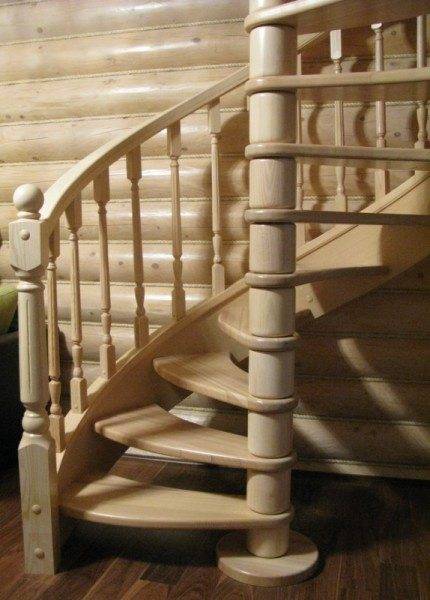

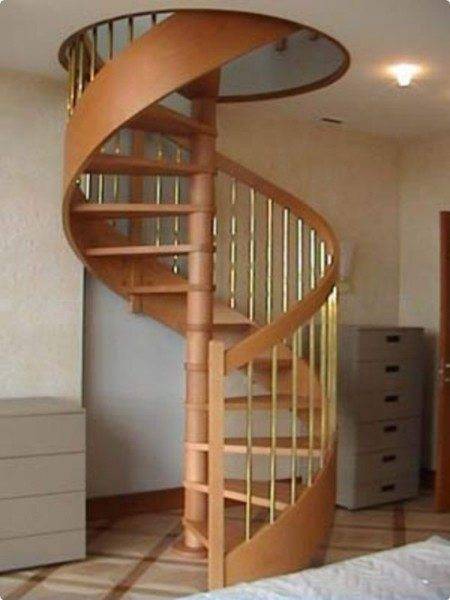

Spiral staircases

These designs are perhaps the most economical among all the options. Only ladders with a steep ascent angle can compete with them, but you will never wait for the aesthetic pleasure that the screw analog guarantees you from the added version.

Recently, it is customary to replace the basic structural element of the central pin with a metal product, and fasteners for steps are also made of metal, although all this can be done from wood.

So, the simplest option is combined:

- Supports for the steps are put on a metal pin, which are represented by a piece of pipe of a larger diameter, equal in length to the height between the steps, on which the support (s) for the step is welded;

- Steps are attached to the supports and they are divorced so that the 18th step is above the first. In this case, 17 steps evenly fill the entire circle, while the height of the step will be within 15-18 cm;

- Fencing. This option is optional, but can be made from any material. The element itself is often more decorative than a supporting one. And in the decor you can use any materials.

Finally

A staircase often becomes a work of art, although the price of this work will be corresponding. The video in this article has prepared its own thread on the topic.

my husband built the simplest wooden staircase in the hallway, and I painted it under Gzhel) such beauty turned out! the main thing is not afraid to experiment