Perhaps it is difficult to find a farm that does not use a wooden ladder. This fairly simple device is capable of replacing a stationary staircase in many situations, and therefore, for private households, it is, without exaggeration, irreplaceable.

Also, ladders and stepladders are often used at construction sites, since before the construction of capital structures, it is necessary to climb the stairs to the upper floors.

In the article, we will talk about the requirements that such a staircase must meet, and also describe the technology of its self-production.

Construction requirements

Applicable standards

Very often, to climb to a height, craftsmen make the simplest structure - two rather long beams are taken, transverse boards are nailed onto them ... However, the operational properties of such structures can be very different, therefore it is better not to risk it, but to be guided by generally accepted standards.

The requirements for the production and operation of ladders, as well as the procedure for testing them for strength, are set out in a number of regulatory documents.

Among them:

- GOST 24258 - 88: Specifications for paving equipment and temporary structures.

- SNiP 12 - 03 - 2001: Labor protection in construction. General provisions (part 1).

- POT RM-012-2000: Regulations on labor protection during work at heights (intersectoral document).

However, the main GOST for the manufacture of structures of this type is still 26887-86 "Ladders and platforms used for installation and construction work."

The information in the above standards is partially duplicated, therefore, if you decide to make an attached structure for personal use, it is enough to familiarize yourself only with the last document.

Manufacturing restrictions

What are the main requirements for attached wooden stairs?

- The maximum length of the structure should not exceed 5 meters.

- The lower support end should be equipped with a special stop in the form of a steel plate or a rubber shoe. The upper part is additionally equipped with removable or stationary hooks.

Note!

Steel shoes are used when working on the ground, rubber - when installed on dense surfaces (asphalt, concrete).

Installation of removable linings is allowed.

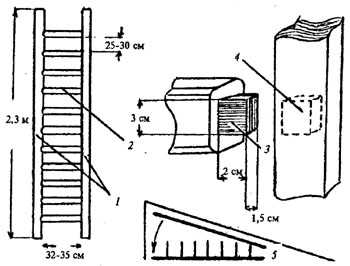

- The step between the steps should be between 300 and 340 mm. Step section - not less than 20x40 mm.

- Each step must be installed in a groove made in a vertical post of the structure (the so-called bowstring).

- Bowstrings are fastened together using tie bolts with a diameter of 2 mm or more. The bolts are placed under the upper and lower steps, as well as along the entire length of the structure in increments of no more than 2 meters.

- Only longitudinal cracks are allowed in wooden bowstrings and steps. The maximum length of the defect should not exceed 150 mm, and the depth should not exceed 5 mm.

Note!

The presence of transverse cracks, chips, as well as other defects that worsen the quality of fastening of elements or the general performance characteristics of the structure is not allowed.

If a ladder is used in production, then an inventory number must be applied to its bowstring, and the area on which it is listed is also indicated. Quality control and strength testing are carried out at least once every six months.

Making stairs

Connection types

Naturally, all of the above requirements apply to stairs used at construction sites and industrial enterprises.For a private house, a simpler design will be enough - but it also needs to be made correctly. Below we will tell you how to make a do-it-yourself wooden ladder. (see also Attic stairs)

To begin with, it is worth deciding on the very scheme of the stairs.

There are several ways to connect a bowstring to a rung, and below we will look at the most commonly used ones:

- Surface mounting... This method of connection is the simplest: boards used as steps are laid on longitudinal bars and fixed with nails. The disadvantage is that you have to stand on the edge of the board, which is very inconvenient.

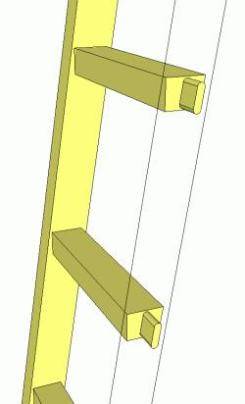

- Invoice with insert... With this method of fastening, the steps are not made from boards, but from square or close-to-square beams. A sample is made under each bar on the bowstring, into which a step is installed.

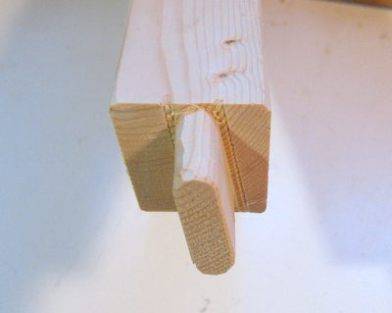

- Spike connection assumes the formation of protrusions at the ends of the steps - thorns. The pins are inserted into the grooves on the bowstrings, providing a secure fit.

Advice!

For the most durable fastening, the spike can be made not straight, but oblique.

Materials (edit)

What do we need for work?

The list of materials is very modest:

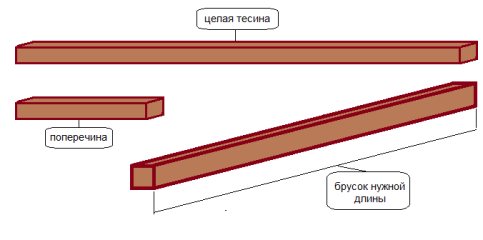

- First, we need two long sticks per string. Any coniferous tree is suitable, as long as it is even, without knots, cracks and oblique layers.

- If the dimensions of our product do not exceed 3 meters, then it is enough to take bars with a section of 40x50 mm. For longer stairs, it is worth using blanks of 40x80 mm: let their price be higher, but we will get a solid margin of safety.

- We also make steps from pine beams. The optimal section is about 35x40 mm. The wood requirements are the same as for the bowstring.

Advice!

For work, it is worth using dried wood, pre-treated with an antiseptic.

Blanks for elements

When the materials are available, you can start work and make the stairs.

The manufacturing instructions are as follows:

- We cut the blanks for the vertical uprights to the required size and process them with a plane. There should be no splinters, knots, etc. on the surface of the beams.

- We lay the workpieces so that the distance between the lower supports is about 400 mm, and between the upper ones - 300 mm. We connect the bars with fastening strips, preventing their displacement.

- We also smooth out the blanks for the steps with a plane. To ensure comfortable movement on the stairs, the corners of the bars are partially rounded.

- We distribute the steps between the vertical supports, observing the standard distance (from 30 to 34 cm). We number the blanks and cut them to length in accordance with the required dimensions.

- Using a furniture router or a circular saw, we cut out spikes 15x30 mm at the ends of the steps.

- Having removed the temporary fasteners from the bowstrings, we hollow out the grooves in them for installing the steps. The dimensions of the groove must be such that the spike enters into it completely with little resistance.

Assembling the structure

After completing these works, we proceed to the final assembly:

- Lubricate the spikes and grooves with wood glue.

- We insert the steps into the corresponding holes on the bowstrings, starting from the upper edge.

- In the assembled ladder, we drill holes under the upper and lower steps, and insert the tie bolts into them. We fix the tie with nuts with a wide washer.

- We also install screeds every 2 meters of the length of the stairs.

When the glue dries, sand the ladder and treat it with wood impregnation. The finished product can be varnished or painted.

Output

As you can see, a wooden ladder with your own hands is quite simple to do. The main thing here is not to take the path of least resistance, but to try to adhere to the requirements for the reliability of the product: this is the only way you can guarantee yourself safety when going up and down. In the video presented in this article, you will find additional information on this topic.