Now almost all developers are erecting even private houses on several levels, at least two, or even three. And many are reconstructing old one-storey buildings, building on one more floor. In one case or another, you will have to deal with the device of a ladder, which is necessary to move to different levels of your house. We will talk about this in our article, as well as how straight wooden ladders are made.

Why wooden stairs

Many developers ask this question while trying to find the best option for their homes. The best choice for private housing is still classic wooden stairs.

Still, natural material is recognized in many respects as the best building material for the entire home and in particular for stairs.

Wooden structures have several main advantages:

- Warm... You will not be afraid for your children, who can paddle the stairs with bare feet, and even just emerge from under the covers. The structure will not cool down so significantly in the cold season, in comparison with metal and reinforced concrete products.

- Consonance with almost any interior design solution... Having looked through samples of wooden stairs in salons, catalogs of firms selling finished products, you will undoubtedly find a design that is ideal for your home. It is easy to combine with other materials, for example, forged handrails of stairs on wooden railings fit perfectly into the interior.

- Practical... They are easy to remove; if necessary, it is not difficult to carry out minor repairs or replace a separate fragment. Although, in fairness, it is worth noting that a skillfully executed and properly processed wooden staircase will last you decades without repair. And the slightest chips that may form during operation are easily covered with special means.

- Available for construction even by people who have nothing to do with the construction industry... Of course, a beginner should not undertake the construction of a complex structure with his own hands, start with a simpler staircase: with straight flights.

Advice!

Also, a novice builder can cope with the installation of a ready-made, purchased structure.

They are always accompanied by detailed instructions for assembling and operating the ladder.

But if you are determined to do everything from manufacturing to installation yourself, this article is for you.

What are the stairs

Wooden stairs, as well as any others, can be constructively:

- Marching.

- Straight constructions.

- Wooden staircase with a turn of 90, 180 degrees.

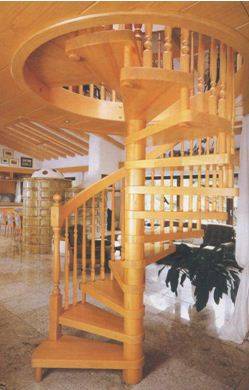

- Screw. If you have enough space to mount your ladder, you can play around with up to 360 degrees of rotation.

The last option looks very nice and takes up much less space than marching ones, but they are rather complicated in execution. It is better to entrust this design to professionals. It is clear that the price of a skilfully executed spiral staircase made of high-quality material can eventually compete with the cost of half of the house.

Therefore, for the experiment of the first manufacture of a ladder with your own hands, the best choice will be a simple marching structure - a wooden straight ladder.

Structural elements of wooden stairs

Before starting work, we will decide on the design of our stairs. Browse the sketches of wooden stairs, which are available in large quantities on the Internet. It doesn’t matter if you don’t find a design that is perfect for your case.

Use the most suitable design you like and modify it on your own. To do this, you need to figure out which nodes of wooden stairs you will have to make and assemble.

Classic stairs made of natural materials consist of:

- Marsha, which, in turn, is assembled from:

-

- Bowstrings or stringers. The difference in bearing elements is noticeable, if in the kosoura it is necessary to cut out under the tread and risers, then it is enough to make a groove in the bowstring.

- Steps.

- Fencing, consisting of:

-

- Pillars.

- Baluster.

For your information!

Balusters of staircase structures can be either single, for example, in the form of carved elements, or they can consist of vertical posts.

-

- Handrail.

- Transition sites.

All parts of wooden stairs can be purchased ready-made. But if you try, then it's not so difficult to make them yourself. The exception is carved support pillars and balusters, which can only be done by an experienced craftsman.

If you do not intend to give up beautiful carved railings, make a combo staircase with partially purchased ready-made parts. Take the rest into your own hands.

How to calculate the stairs yourself

In any case, before starting work, you must complete at least a simple project of your staircase.

What the project includes:

- Constructive solution.

- Calculation of all dimensions of the stairs:

- Tilt angle.

- Step width.

- The depth of the tread.

- Riser height (distance between steps).

- Height and frequency (number of balusters between support posts) of the fence.

- Ladder length.

- The number of steps in the march.

- Installation method.

- Deciding how to cover a wooden staircase.

We have decided on a constructive solution - one-flight straight staircase. Actually, you can measure all the necessary dimensions with finished products, choosing the height of the structure for the required size of your ceilings.

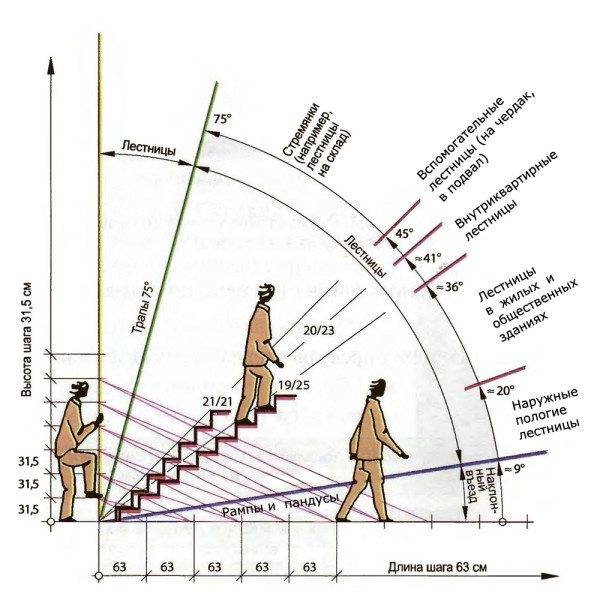

Tilt angle

We start calculating the dimensions of the stairs by determining its slope. For indoor staircases in residential buildings, the angle of inclination of the staircase should vary from 30 to 45 degrees. This range is considered the most comfortable and safest for people to climb stairs, especially for small children.

Climbing stairs at an angle that exceeds the upper comfort limit is tiring and unsafe. It is permissible to arrange such stairs only in small rooms (summer cottages, basements, etc.), additionally reinforcing the fence.

So, knowing the height of the floor and the dimensions of the platform on which the staircase will rest, using a simple graphical method, you can determine the most optimal angle of inclination and other parameters of the staircase.

Attention!

When determining the height of the floor, the thickness of the "pies" of the floor covering on the first and second floors (cement screed, insulation, tiles, parquet, linoleum and much more) should be taken into account.

Graphical method

This method is based on the ergonomics of human movement and is very easy to use.

- Arm yourself with colored pencils, paper and a ruler.

- Draw coordinate axes.

- Divide them into segments equal to the height - vertical, length - horizontal of a comfortable step. Remember to keep the scale.

- From the ends of the segments, draw lines parallel to the axes until they intersect with each other (blue).

- From the point of connection of the axes, draw the main line of the staircase (red), observing the height of the floor and its horizontal projection onto the plane.

- From the intersection points of the red and blue lines, we lower the perpendiculars to the axes (dotted lines).

- Draw steps along the dotted lines.

Changing the angle of inclination of the stairs, reducing or increasing the length of the projection onto the plane (the height of the floor with us is the same value), find the most convenient for you the values of the riser and the depth of the tread, the number of steps. But do not go beyond the recommended parameters for the comfort and safety of stairs.

You can make it easier - install a supporting beam in the opening according to the maximum allowable dimensions for you, that is, how many square meters you do not mind allocating for the stairs. After there is a support, which, of course, is trimmed in place, you can divide the existing clearance by the recommended riser height, taking into account the thickness of the tread. As a result, you will receive the required number of steps.

Other sizes

The size requirements for degrees are dictated by practical considerations. The average step of a person on a horizontal surface is approximately 600-650 mm, and the comfortable lifting height is exactly half that, that is, 300-325 mm. For ease of calculating the size of the steps, there is a formula 2A + B = 600-650 mm, where A is the height of the riser, and B is the depth of the tread.

Advice!

These are the average parameters of the step, but when calculating, take into account the physiological characteristics of all the inhabitants of your house and find the average value individually for your staircase.

As for the width of the steps, there is a fairly wide range of numbers. It all depends on the constructive idea, the area that you can have, the purpose of the stairs. For our simple single-flight staircase to the second floor, the minimum permissible width of 80-90 cm will be sufficient.

There are no strict requirements for the number of steps in a flight of stairs. Recommended from 3 to 18 steps in one flight, preferably always an odd number.

Finishing work and protection

How to process a wooden staircase is decided by the owner himself, depending on personal wishes and preferences in interior design. It can be paints of any color, varnishes, stains, impregnations and other materials.

The main thing is that the coating, in addition to the aesthetic function, reliably protects the structure from:

- Moisture penetration.

- Damage by pests.

- Possible exposure to fire.

Mounting

Finally, how to assemble a wooden ladder.

Having all the necessary nodes of the ladder, you can proceed with its installation.

- We install bowstrings or stringers (depending on what you have), fixing them on the floor, wall and ceiling - the floor of the second floor. Anchor bolts are used as fasteners.

- We put steps and risers on the bearing supports set at the level.

Important!

First of all, risers are attached to the kosoura, and the steps are already pressed against them.

- Then we install the fence posts at a distance of 0.6-1 m. The main posts are installed on landings, parapet steps or the floor, it is better to use steel anchors as fasteners.

- We fill the distance between the posts with balusters in the amount according to the project. Our advice is that you should not indent more than 15 cm between the decorative posts, this dimension is the most optimal for the operation of the stairs by children.

- A handrail is mounted on the support posts. It can be fixed either with glue, having previously made grooves in it, or fixed through the racks on self-tapping screws.

Decorate all visible attachment points and self-tapping screws using special wooden stoppers for stairs. Finish your staircase with some finishing work.

Remember, natural material is very sensitive to temperature changes in the room, so you will have to personally maintain conditions suitable for the existence of a wooden staircase.Otherwise, there is a high probability that the material will begin to disperse and deform.

Output

Now that you know how simple straight staircases are erected, especially if, after reading the above information, you had experience in practice, you can move on.

For example, study more complex types of stairs for the house, understand how they are made, and then try to make it yourself. In the video presented in this article, you will find additional information on this topic.

we made a wooden staircase instead of an iron one, of course, the room was transformed, but filled with new sounds - all this beauty creaks terribly, especially at night it seems that the whole house can be heard))

- all this beauty creaks terribly, especially at night it seems that the whole house can be heard))

For a house of wood or timber, you need to make a staircase of decent material. Then it will last a long time.

Anyway, you will have to hire masters, and this is already expensive.

Natalya, now a normal tree costs so much money that one can only dream of such a staircase. And it will be problematic to do it yourself, you still have to pay the masters. It is very expensive.

And in the bath we made such a staircase ourselves. Out of inexperience, they did not process or cover anything, so at the top of the step we started to rot, now we don't know whether to completely change the staircase or cover it with something?

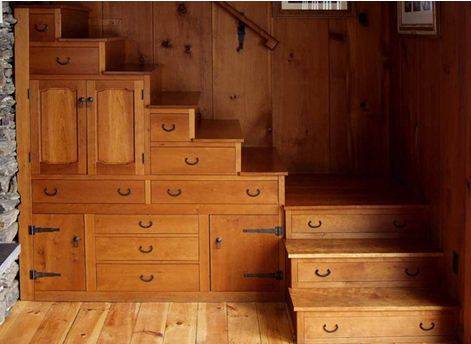

My husband gave me an awesome gift. While I was in the hospital, he built a staircase with built-in wardrobes. Everything is coolly furnished there and for books, and a bunch of all sorts of knickknacks can be placed. I also made a coating, it looks gorgeous. All friends are jealous.