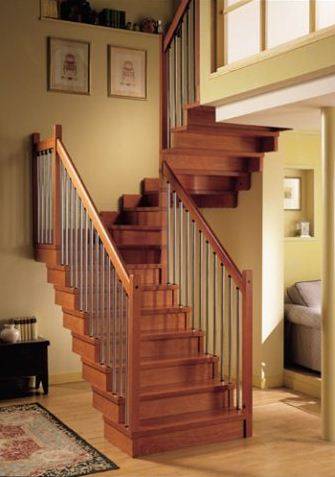

Wooden stairs are an integral part of the layout of any multi-storey private house. Despite the fact that a lot of different materials can be used as a material for assembling the transition between floors: from polished metal surfaces to glass inserts, natural wood remains the most preferred raw material for this purpose.

Since time immemorial, natural wood and stairs have been the most common combination - due to its unique characteristics, wood has been successfully used as the main material for assembling stairs. This trend is observed everywhere to this day - in modern private houses, wooden flights of stairs continue to delight the eye with their natural beauty.

Why tree

The indisputable advantage of wood is its natural texture, which has always been a sign of nobility and elegance. Blanks for wooden stairs practically do not need any additional coating other than colorless varnish, although of course this is a matter of personal preference of the owner and the general interior of the room.

An equally tangible plus is the price of the material - industrial wood, although it does not belong to the category of budget raw materials, has a completely democratic cost in comparison with other analogues. In order to save money, you can use premium grade plywood. Thus, you will lose a little in appearance, but at the same time significantly reduce the cost of purchasing the source material.

Also, the popularity of wood is explained by the fact that, despite its strength and reliability, it is quite easy to process it. This quality is especially important if you are assembling a staircase with your own hands - with other materials, the use of expensive specialized equipment is inevitable.

Marching stairs

Ladders of this type owe their name to their design; its steps are arranged in the form of a straight march. This is the most convenient and simple type of flight of stairs, which is maximally adapted to the characteristics of the human body. The maximum allowable number of steps on one march should not exceed fifteen units, otherwise climbing it will take a lot of energy.

Note!

If the length of the stairs is greater than the standard value and the steps are more than the permissible number, the flights are separated by staircases, the presence of which facilitates the lifting process.

Marching stairs can also contain in their design run-in steps, which are installed at bends and compensate for the absence of a landing. The steps are cut at an angle and completely cover the turn of the march. This solution, although it does not help to reduce physical activity when lifting, will appeal to lovers of non-standard solutions.

The design of the flight stairs implies the presence of a support for the steps, which will serve as the basis for the flight of stairs. The most common are three types of fastening - by means of stringers, on bowstrings and bolts for stairs.

Fixing steps

Kosour

Kosour is a longitudinal beam that is located under the stairs and serves as the basis for the entire structure. Most often there are two load-bearing beams - each of them is located at the edges of the flight of stairs.

On the stringer there are cutouts that correspond to the shape and location of future steps - the lower part of the beams rests on the first floor, and the upper part lies either on the intermediate post or on the upper platform.

Dignity

- Reliability... This type of construction is the most reliable of all existing analogues - thanks to the load-bearing beams, the steps of the stairs can withstand the maximum load;

- Simplicity of design... The steps lie directly on the supporting beams, so there is no need to install various kinds of fasteners and clamps - the instructions for installing stairs of this type have a fairly simple structure;

disadvantages

- Appearance... The ladder on the stringers is less aesthetic compared to the fastening on the bowstrings, since the beams remain in sight and it is not always possible to disguise them;

- Straightness... The presence of kosour implies the presence of right angles - the installation of smooth turns or complex figures will be accompanied by difficulties during installation;

Bowstrings

This is a more aesthetic method of fastening staircases - in contrast to the stringer method, the steps do not lie on top of the load-bearing beams, but are attached from the inside on the side. In this case, it is necessary to have two load-bearing beams along the edges of the flight of stairs.

Dignity

- Aesthetics... Since the beams are located on the sides of the steps, they do not need additional decoration or masking and are part of the interior of the staircase;

- Flexibility... Bowstrings allow you to form various directions and turns of the stairs without seriously complicating the installation process;

disadvantages

- Strength... The strength potential of steps for this type of fastening is much lower than the previous analogue, since the main load falls not on the supporting beams, but on the fastening of the steps. This disadvantage is not decisive, since the margin of safety is quite enough for the safe operation of the ladder, however, when transferring weights, it can make itself felt;

- Complexity of installation... For the installation of fasteners, various clamps and grooves are used, which greatly complicates the installation process;

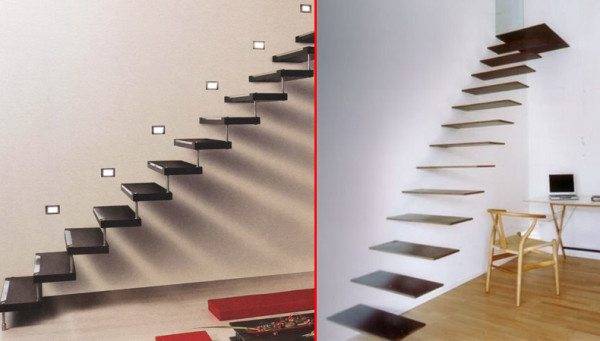

Boltsy

Boltsy is derived from the German word “bolz”, which means “pin” or “bolt”. This type of ladder is suspended on fixtures in the space of the room - a wall is used as a load-bearing base. The staircases on the bolts have a weightless and graceful appearance, which is their characteristic difference.

Dignity

- Aesthetics and compactness... The absence of external fasteners makes the ladder on the bolts the most aesthetic and original option. It also helps to save space, without losing convenience and comfort;

- No squeak... Since the steps are fixed on suspension mounts, there is no wood-to-wood connection, which prevents the occurrence of a squeak;

disadvantages

- Wall mount... The steps are fixed directly to the wall, that is, the flight of stairs can be located only near the load-bearing walls;

- Strength... Despite the fact that the mounts are designed for a certain weight, their potential is limited and is only suitable for daily use without the presence of additional load.

Outcome

Marching stairs made of wood are one of the most convenient and reliable options for communication between floors today. Correctly selected components will make its operation as comfortable and durable as possible. The video in this article will demonstrate visual information on the topic.

Very literate and at the same time not a standard solution with a run-in step in 4 fig. Looks very, very cool. there is only one thread on the support. How many I have already revised the options for marching stairs, and this is the first time I see it. But there is a problem here. such a staircase costs a lot, of course there would be money, there are no questions, but you only have to admire

I am used to doing everything in the house with my own hands, therefore, having considered all the options for stairs made of wood, I would choose a marching staircase. This option is the most affordable for making with your own hands and looks good. True, now any version of a staircase made of wood will not be budgetary, since wood, especially hardwood, is now expensive.

Will anyone really think of making a "boltsy" staircase in their house? Yes, it looks elegant in the picture, but these are all its advantages, and in the house it will certainly lead to injury sooner or later.

Wooden staircases have been built since time immemorial, not only because of their aesthetics, but also, most importantly, because of their low cost in comparison, for example, with metal ones. In addition, if properly processed, it requires less maintenance: it does not rust, the paint does not come off.