A beautiful wooden staircase will be an excellent decoration for any home. But, in addition to its attractive appearance, it must also have reliability and durability. All these qualities are endowed with beech wooden stairs.

To acquire such a design, it is not at all necessary to order it from a specialized workshop. This product is quite possible to make yourself. We will now tell you how to do this.

General staircase arrangement

To begin with, it is worth examining the device of this product. We will need this in the process of further work.

First of all, we note that the staircase is a prefabricated structure consisting of separate elements.

Let's call them:

- steps - are composite, have a top and side plane... The first is called a tread, the second is a riser. The step width is usually about 30 centimeters. The length ranges from 90 to 150 centimeters and sets the width of the entire staircase;

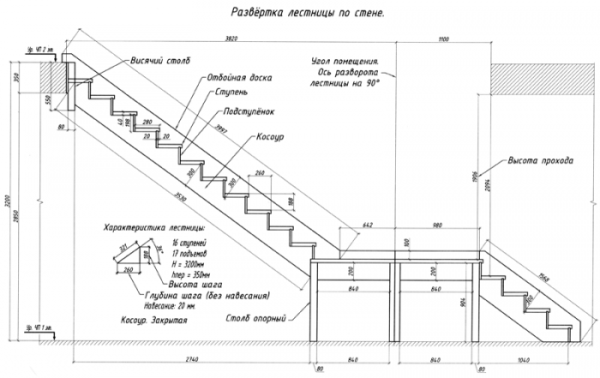

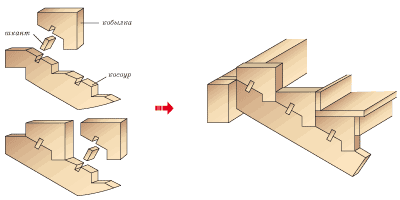

- support beams - perform a load-bearing function, since all other elements are attached to them... The beam can be in the form of a kosour, which has triangular cutouts for the steps of the stairs, or bowstrings, where instead of cutouts there are special grooves. The support post is another type of beams, the peculiarity of which is that it is used in screw structures;

- handrails - needed for the safe operation of the stairs... They consist of an upper part - a handrail and lower elements - balusters. Made of wood, they come in a wide variety of shapes, giving an elegant look to the structure. This is especially true when applied accessories for wooden stairs from beech.

One should also mention such a thing as a march. This is a certain number of steps and handrails connected together. There can be one or several marches throughout the structure. In the second case, they are separated by a staircase or run-in steps.

Why exactly beech

This choice is quite justified.

After all, this material meets three main criteria by which buyers evaluate this product:

- acceptable cost - beech is more expensive than a number of other types of wood, for example, conifers, differing from them in their durability and strength. And it's worth paying for;

- practicality - unlike the same pine or spruce, beech material can be used for intensive daily use. At the same time, it will not deform. He is also not prone to quick wear;

- attractive appearance - this material looks very beautiful and remains so for a long time

Nowadays, it is beech that is very often used in the creation of stairs.

This is explained as follows:

- it has excellent performance characteristics, lends itself well to heat treatment, is durable, capable of withstanding increased loads;

- the steps from it are very comfortable and practical;

- beech is a good alternative to oak, the price of which is very high;

- low porosity of the material prevents the appearance of cracks on the surface of the steps;

- noble texture allows you to implement various design solutions.

Beech wood stairs

We will consider the process of creating such a product using the example of making a flight staircase, since this is the most used type of structure. Their popularity is easy to explain, because they are reliable and easy to manufacture.

Advice!

Beech processing is a very time consuming process.

Therefore, details such as steps, handrail and stair balusters are best made from pre-purchased blanks.

You can buy them at a hardware store or a specialized firm.

This will save you a lot of time and effort.

Design

The first step in our process is design. It is very important. Any mistake made in the project is fraught with serious problems during assembly and further operation. Therefore, please be extremely careful about all calculations.

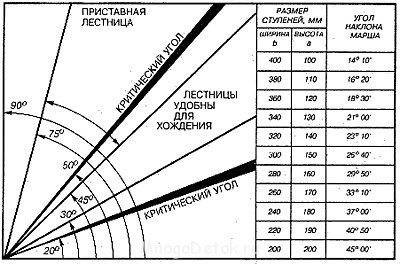

We have to develop three types of elements: stringers, steps and handrails. We'll start with the first item. We will calculate it using the following formula: 2a + b = 64 cm.

In this case, the variable "a" will mean the width of the stringer, "b" - its height. The second parameter is usually 14-17 centimeters.

First, we measure the height of the stairs with our own hands. Then we divide it by the value of the variable "b". This will allow us to get the number of rungs in the staircase.

Let's consider this with a specific example. Let's say we measured the overall height of the product and ended up with 240 cm.

We mark the height of the step at the level of 16 cm. Divide the first number by the second and get 15. This is the number of steps our product will have.

Now let's start calculating the parameter "a" from our formula, that is, the width. Since we know the variable "b", it will not be difficult to do this.

You can use another way. Namely, use the table below for calculations.

Advice!

The tread may have a slight protrusion above the riser.

Such a protruding part should not exceed 3-4 cm in length.

If it is larger, the steps will become uncomfortable for walking - it will be easy to trip over them.

There is one important pattern in the design of stair structures: the higher the beech steps for stairs, the smaller their width should be. But, at the same time, the upper part of this element should not become narrower than the side. Otherwise, it will be difficult for a person to climb up.

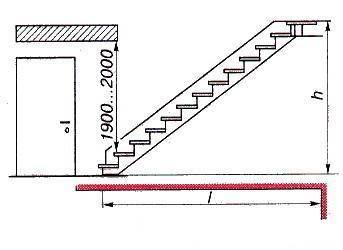

It is also necessary to take into account the following: the distance from the steps to the ceiling slabs should be at least 190 cm. This is necessary for the convenience of moving tall people.

Now we have to calculate the future horizontal size of the entire product. To this end, we multiply the width of the steps by their number. Do not forget to take into account that the first of these is gender.

If, according to the results of calculations, the total height of the building turned out to be too large, then you will have to make a staircase. To do this, we divide one existing march into two. Each of them will be 7-8 steps.

If you need a strictly defined number of them, then you can reduce the height of the riser. This step will help you place the pad.

Creation of kosour

For their manufacture, you can use ready-made elements of beech stairs, the dimensions of which will only have to be slightly adjusted. Alternatively, use appropriate boards with a thickness of 40 mm.

We carry out this work as follows:

- first, we will make a pattern that will exactly repeat all the bends of the steps. We will use it to mark the workpiece. We draw the lines in such a way that the resulting teeth are without an acute angle;

- we pick up a hacksaw or an electric jigsaw and start cutting out the edges. After completing the process and receiving the finished part, we use it as a template for creating the rest of the stringers.

We need 3-4 units of them. This number is enough to ensure the safety and reliability of our product.

We mount steps and railings

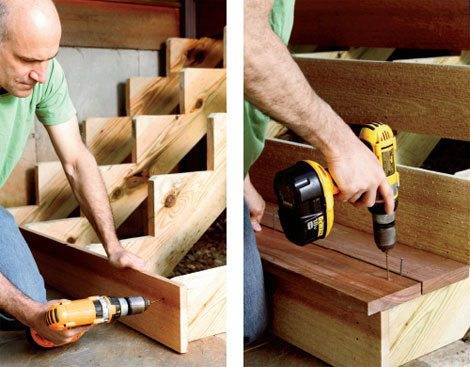

Our instructions for the manufacture of beech wood stairs, the next stage of work, installs the installation of steps and railings. We fasten the first of them with the help of special blanks - filly. You can do without them by fastening the elements directly.

But first you need to prepare the required number of risers and approaches. And only after that you can go directly to the installation process.

When creating elements, do not forget about the protrusions, as well as their sizes. Having started the assembly, we carry out it using self-tapping screws or nails.

The previously mentioned method of fastening using filly is more reliable. To do this, first we will make triangular blanks.

We will prepare grooves specially for them. Then, with the help of dowels, we fix the blanks in the grooves.

The connection will be even stronger if you use filly of complex shape. For them, special grooves are created in the stringers. After that, the elements are fastened with self-tapping screws and glue.

Having finished working with the steps of the stairs, you need to move on to creating the railing. Their installation begins with the installation of balusters. These accessories for wooden stairs can be of a wide variety of shapes. The use of certain stylistic elements will allow you to organically fit the building into the overall interior of the room.

The handrail is no less important here. We proceed to its installation after all the balusters are installed.

After completing the installation, let's move on to finishing the resulting product. Painting is mandatory in this case. After all, it will help protect the wood surface from various harmful factors that negatively affect the condition of the wood. These include dampness, harmful insects, and mold.

Output

The beech wood staircase stands out favorably against the background of other similar products. It is reliable, durable, and has a beautiful appearance. In addition, it is suitable for daily intensive use.

You can make such a design at home. To do this, first of all, you should do the design. Moreover, this process must be approached very responsibly and carefully. Errors are unacceptable here.

In the process of creating this product, it is worth using ready-made elements of a beech staircase. Their use will greatly simplify the course of this work. We also recommend not passing by the video in this article, which contains equally useful information for you.

I decided to build on a wooden staircase in a summer cottage on the second floor, did not pay attention to the distance from the steps to the ceilings and now I walk around with my head, but it doesn't matter when you realize what you have done with your own hands.

Beech is an expensive tree to process it is hard no one knows if birch is used for making stairs? There are a lot of birch trees in our area, but there is no beech at all. I don’t want to order it. What's the difference from what to make a staircase, our native birch will suit better than beech!

The beech, of course, has an attractive appearance and I also agree with its practicality, but the author clearly exaggerated the acceptable cost. Tips are good, but if I had such material, then I would have done better it seems to me