In most cases, as soon as it comes to a spiral staircase, it seems cast iron product, however, metal is far from the only material from which a spiral flight can be mounted, say, on the second floor of a house.

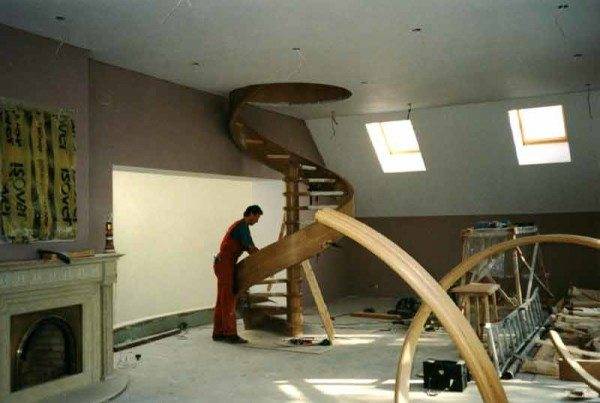

We build a screw structure

In addition to metal, today glass with stainless steel and wood are used in the production. It is the last option that is most accessible for self-construction.

Important!

If you have tools, and most importantly, a step-by-step guide, it is possible to build a screw flight.

Advantages and disadvantages

However, like every design, the spiral version of the staircase has both indisputable advantages and disadvantages.

Speaking of the pros, compactness is always put in the first place. Indeed, wooden and spiral staircases save usable living space, which is especially important in small spaces.

Important!

Interestingly, the total area of the structure that will connect the first and second levels of the house is, with a ceiling height of 2.5 - 3 meters, only 2 square meters!

In this case, it is possible to design both the required level of inclination and the required height of the steps.

The second huge plus is the relative cheapness of this option. And it is difficult to argue with this, because, in comparison with cast iron or glass, wood is a material that is several orders of magnitude more economically profitable! And the fact that the structure will be assembled in-house helps to further reduce costs.

In addition, a do-it-yourself wooden spiral staircase is also a significant saving in material. After all, if you count the area of an ordinary flight of stairs and a spiral staircase, then the difference is simply enormous!

The dignity can be safely attributed to the appearance. The aesthetic component of any staircase is always important, and wood is a material that makes it possible to embody many design ideas, coupled with screw mounting.

At the very least, you can guarantee that spiral wooden staircases for a summer residence, for example, will certainly be noticeable, if not the main elements of the interior.

The disadvantages always include issues of an ergonomic nature and movement.

Briefly, you can describe all the cons as follows:

- Inconvenience in operation.

- Lack of ability to lift heavy furniture, wardrobe, sofa up the stairs to the second floor.

- A more complex process of movement, it is always difficult to go up and down on a screw structure.

We can say that a spiral staircase made of wood + created with your own hands must necessarily imply the option of a normal, straight-line march, or other ways to raise the necessary pieces of furniture to the second level, for example.

Important!

When designing, special attention will need to be paid precisely to the width of the steps and their number, and, of course, to reliable fences.

Where does it begin

Any work on creating a staircase always starts with a drawing, a project, and before that - with calculations.

To begin with, you need to accurately calculate what dimensions the product will have, and you will have to take into account several nuances:

- Total area of the room... Ergonomic design principles must be observed.

- Options with raising bulky structures to the second level, the width of the stairs in a private house in this case will need to be calculated in large sizes.

- The height of the degrees... If children live in the house, it is necessary to take this moment into account, and design the march in such a way that it is convenient for everyone to move along it.

Next, you need a fixing solution.All do-it-yourself spiral staircases made of wood, or ordered from the manufacturer, can be attached to the support post. This is the most common and technologically correct mounting option.

Moreover, the support pillar can be located anywhere, respectively, it is possible to design the passage to the second level based on the capabilities of the spiral staircase.

In addition, it can be mounted to a wall. In this case, the wall will be an additional support element that will give the entire structure the necessary rigidity.

Calculations

Before approaching the calculations, it is worth mentioning a few main points in the choice of material:

- The treads are made of hardwood such as beech, maple or oak.

- Railings and bowstrings are made of glued wood.

- The post can be any, made of wood, iron, stone, but the most optimal option is a steel pipe.

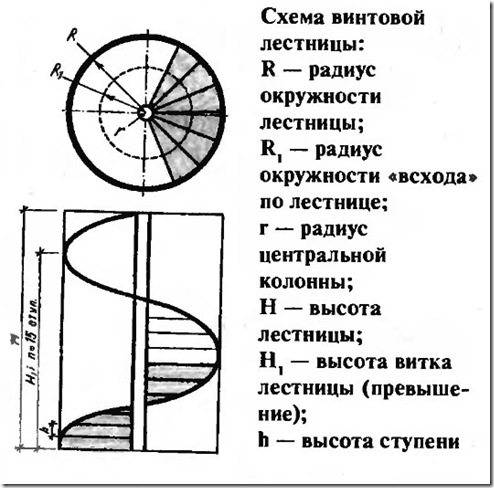

An instruction on how to carry out calculations can be demonstrated with the following example:

- The optimal staircase width is 0.9 meters.

- The height of the structure is 3 meters.

- Metal pipe with a diameter of 0.2 meters.

Important!

Calculations will be shown in relation to these figures, respectively, you can always replace this option with your own sizes and make an individual calculation.

- It turns out that the total diameter of the structure will be equal to twice the width of the steps and the thickness of the steel pipe - 0.9 x 2 + 0.2 = 2 meters, this is the diameter.

- Further, the radius of the circle along which the person will climb is considered. Here, the values of the sum of half the width of the step and the radius of the support pillar are taken - 0.9 / 2 + 0.2 / 2 = 0.55 m.

- The calculation of the steps assumes one turn of the staircase and is considered with the value of the radius of movement of a person and the width of the step (width 20 cm), 2 x 3.14 x 0.55 / 0.20 = 17.27. That is, 17 steps are required per turn.

Important!

Since a wooden spiral staircase can be made according to any calculated dimensions, the dimensions of the structure are selected based on the necessary requirements for the room.

However, the best option for the step width is 30-35 cm, and the radius of movement for a person is 0.8-0.9 meters.

Next, the height of the steps is calculated. Here you will have to take into account such an interesting indicator as a person's height.

Step by step, everything looks like this:

- The circle is divided into 15 equal parts by radial lines.

- The first step of the loop and the last one is a kind of line that determines the height of human growth. In this case, a small margin is made and another 15 cm is added.

- The height of the turn is calculated with an increase of 185 cm, a step thickness of 0.5 mm and plus a margin of 15 cm. The turn is 2.05 meters.

- The height of the steps in the loop is calculated, 2.05 / 15 = 13.67.

- Further, you can calculate the number of steps, for this, the height of the structure is divided by the height of the step. 3 / 0.1367 = 21.94, or 22 steps.

Steps and railings

You can make steps with your own hands using durable varieties of wood, and the easiest way is to purchase ready-made steps, from which you can make blanks of the required shape.

After the steps are adjusted to the desired size, they are finished, polished, rounded off the edges, then painted with varnish. After that, special bushings are fastened, it is with their help that the steps will be attached to the support post.

Railing balusters can be made from metal rods, but handrails work well if you use glued laminated timber or plastic. Handrails for self-assembly are easiest to use simple, rectangular, which are represented by bars of a certain size.

Assembly

Making wooden spiral staircases with your own hands involves three main blanks:

- Steps.

- Railing.

- Support post.

If you have all three, you can start assembling. Schematically, the assembly process for a home or for a do-it-yourself summer cottage can be displayed as follows:

- Ladder fittings, bushings, fasteners are fixed on the steps with bolts.

- Then, step by step is strung onto the support pillar.

- The post is installed in a pre-prepared place.

Important!

The base of the post must be on a solid foundation.

You can even pour part of the base separately, laying in it mortgages for fixing the pillar.

The support tube itself is bolted to the floor.

- The support pipe is fixed to the floor and ceiling.

- All steps begin to be located with a certain overlap of each other and are fixed with the help of bolts.

- Further, the balusters are attached to the steps.

- Railings are attached to the balusters.

Important!

The baluster of the first step in the structure should be of great length and becomes the base on the floor.

It is fastened to the floor, and this provides additional rigidity to the entire structure.

Output

The economic component of self-manufacturing of a screw structure is quite attractive. The price of work, materials, accessories, is quite low and allows everything to be done with minimal costs.

However, it is worth mentioning that this is a rather complex process, requiring accurate calculations, some knowledge of geometry, and the ability to work with wood. Drawings and assembly diagrams, of course, will help a lot, but the rest depends only on perseverance and attentiveness. And in the video presented in this article, you will find additional information on this topic.

Now we are building a house. Winter is over and a lot of activity will begin. Cool, of course, they told everything, but I agree that we must proceed from our plans and wishes. Personally, I don't really like these stairs. Close as for me, even if the size is increased, well, this diameter is still somehow not for me. We will have this family estate and I want to have space, but this option is cramped. Hots for someone can and will be acceptable, why not. Yes, and now a lot rests on money, everything must be really well planned. In general, it does not suit me, although the advice is really competent.