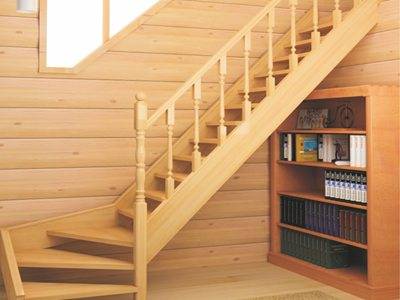

Individual construction in the modern world initially implies the presence of several floors, and for a comfortable movement one cannot do without a special structure. Most often, developers arrange a staircase in a wooden house with their own hands, and the main material is the same wood.

As for metal, concrete and stone, there are certain difficulties when working with them.

Characteristics

Choosing such structures as a means of moving to the next or previous level of the living space, the owners get live energy, natural smell and warm texture. In addition, the systems can be successfully combined with other materials if necessary. However, in everything there should be measure and professionalism, then the wood will demonstrate its capabilities.

The presence of important advantages

- Ecological cleanliness, provided by nature itself, in this regard, cannot pose a danger to the human body. Some breeds even have the ability to heal.

- Availability due primarily to the presence of vast forests on the territory of our state. For this reason, such materials are available on the market in a wide range.

- A light weight allows you to do without additional reinforcement of the bearing beams, and also provides an opportunity to reduce costs when transporting individual elements.

- The use of special operations such as patination or gilding can greatly expand design solutions.... In addition, the surface can be painted in any color.

Note!

Modern staircases in wooden houses are more and more often made of laminated veneer lumber, but other lumber made from valuable and durable species are also used in the process.

Negative points

- Weak level of fire safety, although recently, with the help of special compounds, this figure can be increased. However, then there is a need for additional processing.

- The tendency to decay increases only if the elements have not been coated with special biological protection agents. Usually their price is not that high.

- Changes in shape and size due to shrinkage, especially with severe fluctuations in air humidity and temperature. However, the premises, as a rule, have a favorable microclimate.

Attention!

Despite the listed disadvantages, such stairs for a wooden house can be protected with antiseptics, which can increase the operational period.

Design options

Before carrying out work, the type of structure is determined. The choice is influenced by the design solution of the entire room, as well as the size of the internal space. In total, there are three basic options, thanks to which you can carry out a comfortable climb to the next floor, while their appearance is quite good.

Main types

- Marching structures include inclined supports that serve as the basis for the steps. Two ladder bowstrings or stringers with kerchiefs act as structural elements.

- Screw assemblies fit into a circle with a small diameter without any problems. Placed in a circle, lifts minimize the use of useful squaring.

- Swivel stairs in a wooden house are installed when you need the opportunity to climb a step on a headland. The site in this case is a single attack.

Addition!

A widespread and at the same time the most convenient option for a room with a ceiling height of about 280 centimeters is a design with two flights and a quarter turn.

Manufacturing process

When purchasing processed boards, attention is paid primarily to the condition of the surface, which should not contain gray areas, cracks, roughness and other defects. The presence of fallen knots is allowed if their diameter does not exceed 1 cm, and the board itself will not be used as load-bearing parts.

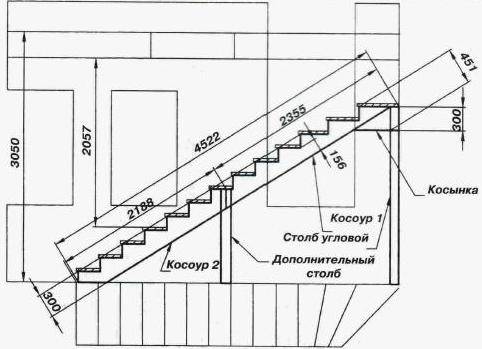

Design guidelines

- If a rotary staircase is arranged for a wooden house, then the optimal number of corner steps is chosen. It is recommended to do three lifts with a width of 80 centimeters.

- When the opening is located only above the upper part, the height to the ceiling must be taken into account, otherwise it will not be very comfortable to pass, especially if the distance is less than two meters.

- To calculate the size of the projection, you need to determine the width of the rise. As a rule, it is 250-300 mm. By multiplying the selected distance by the number of steps, you can get the final size.

Required tool

Do-it-yourself high-quality manufacturing of a staircase in a wooden house cannot be done without a certain set of equipment. A reliable and aesthetic design is erected only with the help of special tools.

If you do not impose special requirements, then it is quite possible to get by with a hammer and a hacksaw.

- Drill or screwdriver for the possibility of fastening using self-tapping screws.

- A hacksaw for cutting system elements.

- A plane to help ensure the fit of the component parts.

- Sandpaper for grinding components.

- Tape measure, ruler, square for measuring distances and pencil.

Note!

Depending on the chosen method of carrying out the work, operating conditions, as well as fastening the elements, the equipment may slightly differ from the one mentioned above.

Bowstring construction

Such stairs are arranged to a wooden house or to the second floor and represent a traditional variety. The advantage is a fairly high strength, but besides this, the structure looks quite decent.

It is used both in classic style and in modern decors.

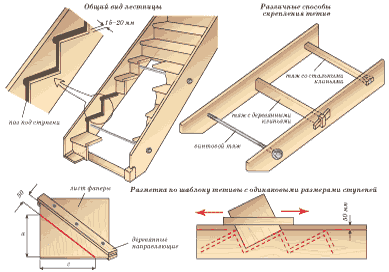

- Using a suitable tool (electric jigsaw or hacksaw), two or more bowstrings are made. Cutouts are made along the entire length with a chisel for steps or additional supports are knocked out.

- The fitting of individual elements of the staircase is carried out, which, if necessary, are adjusted to the required dimensions. Also at this stage, sanding is performed.

- The entire structure is being assembled using a screwdriver and self-tapping screws. In this case, it is recommended to lubricate the contact points of the components with wood glue.

- First of all, vertical parts are installed, and only then horizontal steps are installed, the protrusion of which can be from 2 to 5 centimeters.

- Installation is carried out using steel corners directly between the two floors, although the entrance staircase to a wooden house is installed in about the same way.

- The assembly of the railings and balusters begins. Depending on the stylistic solution, their appearance can vary greatly in each case, but the installation technology is the same.

Important!

If the baluster significantly exceeds the dimensions of the bowstring, then an additional board is fixed to the support bar, which makes it possible to expand by 20-30 mm.

Kosoura system

The load-bearing elements of such a flight of stairs are wide bars with a comb in the upper part for installing steps. When viewed from the side, the lifting end can be seen.

In modern interiors, such designs are quite popular.

- A blank is carried out along the length of the entire march, after which the angles of fit are calculated.

- After pre-installation in place, the steps are marked. With the help of a pencil, the main contours are drawn.

- Next, lines are marked along the supporting beams. Thus, the intersection with the horizontal stripe is considered the inner corner of the step.

- With a circular saw, cutouts are made strictly according to the marked markings for all ascents.

- Prepared stringers are fixed in place. At the same time, their placement relative to each other is checked.

- The cuts and vertical supports are placed on the cutouts made in the supporting strips.

Recommendation!

Experts advise, immediately before work, to create a detailed drawing of the future structure, where all restrictions and operating conditions will be taken into account.

Finally

A special video in this article will help to supplement the information on this topic. After viewing, you will be able to get answers to your questions while studying the instructions given. Before starting work, it is advisable to have an idea of \ u200b \ u200bthe creation of interfloor structures made of wood.