The construction of country houses implies the presence of a second, and sometimes even a third floor. How to get "up" in another way, if not by stairs? For real owners-builders in this article, a diagram will be described in detail - how to make a staircase with your own hands. By the way, it finds application not only in suburban construction, but also in the now popular two-level apartments.

If we talk about the materials that are used to create the stairs, then figuratively there are as many as there are letters in the alphabet. In this case, wood will be considered, which has proven itself as a lightweight and durable (with proper processing) material, also appropriate in a residential building from an environmental point of view.

Wooden stairs have never gone out of fashion in terms of design solutions, and in terms of processing timber and boards, this is available to everyone who understands how to hold a plane and a screwdriver in his hand. To understand the described advantages of wood, it is enough to compare them with a concrete or metal staircase, requiring a welding tool or renting a concrete mixer.

Ladder calculation

Before building a staircase made of wood, you need to have a clear construction plan and a detailed calculation of the cost of consumables. Knowing the height from the floor of the lower floor to the top point of the ceiling, you can start designing.

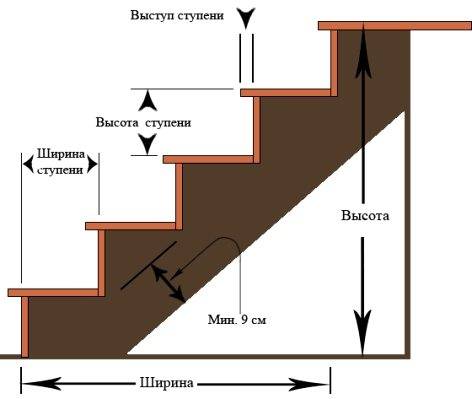

Usually, in country houses, ceilings are made no higher than 2300 mm, so the dimensions of the stairs will be 30-40 centimeters larger. Next, you need to determine how many steps the staircase diagram includes. It depends on the step height.

Tip: choose the optimal step height for the stairs within the range of 18-20 cm.

Illustrative example

Suppose that a step height of 18 cm is taken as a basis, then in order to understand how many steps to make, it is necessary to divide the total height of the stairs by the step height. As an example, with a ceiling height of 270 cm, we get: 270/18 = 15 pieces.

Of course, such calculations are not entirely accurate, because the thickness of the step absorbs a small step distance and much depends on the angle at which the stairs are installed and at what angle the steps are placed.

Tip: choose a tread width within 25-30 cm, but no more.

It is always recommended to take a little less, because children, pets, and elderly people who have poor vision will go down the stairs. In order not to stumble, we take a tread of 25 cm.It remains to multiply this figure by the number of steps and get the final projection of the staircase to the floor - 3m75 cm.

How to understand from this what the length of the staircase will be in the end? Imagine a right-angled triangle with leg 1 - the projection of the march to the floor, leg 2 - the height of the ceilings to the upper point of overlap.

According to the Pythagorean theorem, we calculate the hypotenuse, it is equal to 4m 62 cm, this will be our ladder in practice. Of course, the spiral staircase scheme implies a slightly different calculation, but parameters such as step height and tread width should be taken into account in this case as well.

Staircase installation work

The second stage involves construction and installation work, for which you will need previously purchased materials and improvised tools:

- Drill, brace - for making holes for hardware;

- A hacksaw for cutting wood or an electric saw;

Tip: It is better to have two, one with a large tooth, the other smaller, with two millimeters.

- A screwdriver and bits to it, which will be used during installation according to the diy ladder fastening scheme;

- Chisel;

- The hammer is "light", weighing up to 200 g;

- Planer for processing and fitting parts;

- Sandpaper for sanding steps and handrails;

- Measuring tool - tape measure, level, ruler;

- Bolts or screws for fasteners. They can be purchased at a furniture hardware store or at the construction market;

- As well as a pencil and gloves for work.

The correct choice of materials plays a very important role in this situation. Wood for these purposes is selected from the first grade, preferably from aspen or pine. Determine by weight how high the moisture content of the board is by holding it in your hand. Purchase ready-made planed wood for work, which does not have extra large knots and burrs.

Tip: make sure that the arrangement of knots is no more than 1 piece for each meter of the board.

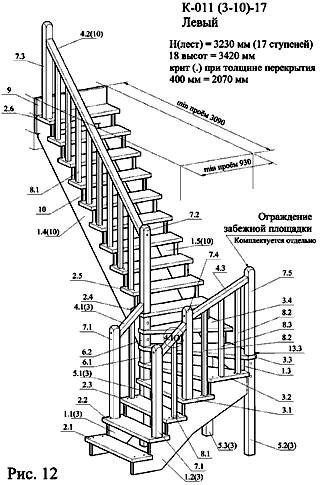

You should first think about how the staircase switch circuit will be located, what the width of the staircase will be, whether you need carved railings. Answers to these questions will allow you to calculate everything in advance and save money, but on the other hand, you cannot bring savings to recklessness and sacrifice safety.

First of all, we advise you to cut the kosoura from a 140x60 bar, and then make the required number of steps from a board, the thickness of which should be at least 30 cm. To them from the same material, or a slightly thinner board (up to 25 cm), cut risers.

Putting the ladder together

Recommendation for owners and builders: before proceeding with the assembly of the finished designer, it will not be superfluous to try on the parts and, if necessary, adjust them.

The same applies to the scheme of metal stairs.

Let's consider step by step the entire assembly and installation process:

- Grind, clean and bring the steps, railings, risers to normal condition. Particular attention should be paid to the ends;

- With the help of stain (or hot varnish) and wood varnish, the product is covered in two or more layers, as required by the instructions for the varnish. Cover the joints with tape so that you can then apply glue there;

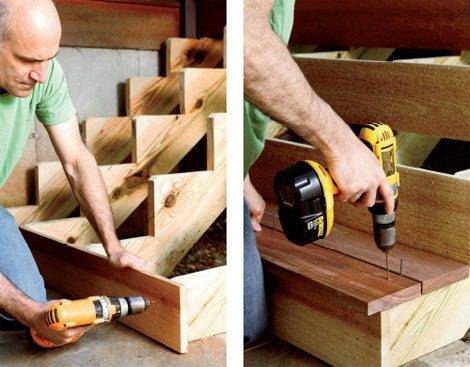

- Now, using a screwdriver, we fasten the surfaces to each other, having previously coated it with glue. In work, use only stainless screws, and both carpentry and ordinary PVA are suitable as glue;

- They start cutting grooves under the steps in the stringers. Here they use a chisel and connect a hacksaw;

- In the grooves, holes are drilled for bolts with a slot for a slotted bit. The hole diameter is usually 9 mm;

- Insert the steps into the grooves, marking the place for the bolt through the hole with a pencil;

- Take out the step and drill a hole under the turbo coupling for the M8 bolt. Hole depth 3-4 cm;

- First, the turbo coupling is screwed into the step, and then the structure is placed in the groove and fixed with a bolt;

- According to the same scheme, ready-made railings are attached, cut from a bar and assembled separately from the steps.

The chosen type of fastening of the steps is distinguished not only by the price, but also by the reliability of the connection of the parts: the ladder will serve you for many years. You can also use furniture screws, for this, preparing a hole in the step a couple of millimeters smaller.

As a result, you should get a ready-made ladder that is easy to assemble yourself, or to attract a couple of working hands for this work. As for the beautiful carved stair balusters in the railings, their owners often order them from carpentry workshops to order, choosing a shade to match the color of the stair steps, and then mount them as required by the staircase assembly scheme.

conclusions

As can be seen from the materials of the article, everyone can independently make a wooden staircase to the second floor, and for this it is not necessary to have a special education. As for more complex and combined schemes, for example, such as a staircase with a metal frame and wooden steps, then you should soberly assess your skills and level of skill.

In the video presented in this article, you will find additional information on this topic.