Two-storey private houses have become an especially popular type of construction in the last 10-20 years. Even on a small plot of land, it is possible to build housing that will have sufficient area for an average family, while saving several tens of square meters of territory.

As a rule, in such houses on the first floor there are a kitchen, a dining room, rooms for receiving guests, and on the second there are bedrooms, children's rooms and study rooms.

Low-rise private house - the best solution for a family

When building two-story houses, it is necessary to take into account and implement one very important condition, namely, it is necessary to build a staircase that will provide convenient and safe access to the second floor or attic.

Since the modern building materials market meets the demand for almost any goods as much as possible, you can buy ready-made copies in specialized stores, and you just have to mount the staircase and install it in your home.

Unfortunately, ready-made solutions do not always suit the homeowner completely, and there are several reasons for this:

- sizes do not fit;

- not satisfied with the design;

- don't like the material or finish;

- high price.

Choosing the design and material for the stairs

Since the staircase in the house is vital, and there is no suitable ready-made structure on sale, you will have to make it yourself. This will require some tools and skills to handle them.

Before starting work on the manufacture of steps, balusters, railings and other elements, you need to decide which type of staircase is most suitable for your home, and from what materials you will make it.

When deciding on the choice of material, you, first of all, will depend on your financial capabilities.

Possible options:

- wood,

- metal,

- reinforced concrete.

Wood is the most environmentally friendly and preferred material, but oak or beech used to make parts is very expensive. Therefore, if the question of money is acute enough for you, you can dwell on structures made of metal or concrete.

Such stairs are as strong and hardy as possible, and if desired or necessary, they can be decorated:

- less valuable wood species;

- laminate;

- ceramic tiles;

- any other facing materials.

Attention! To avoid injury, it is recommended to choose anti-slip tiles for stairs. This condition is especially important for stairs located on the street (porch), and in the hallway, where water from the street may appear on the floor.

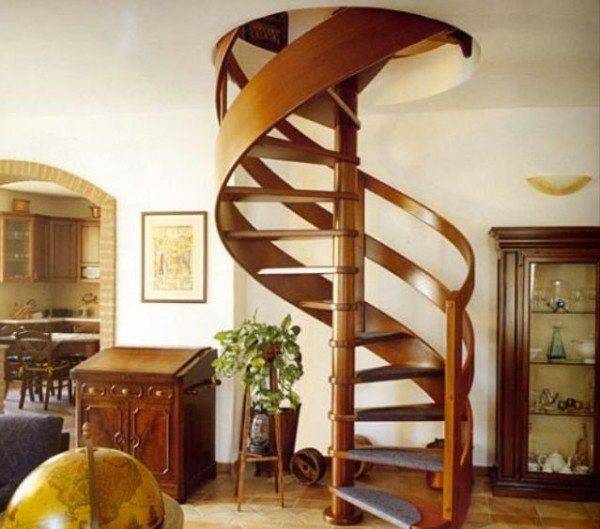

Structurally, stairs can be divided:

- one-march,

- two-march,

- swivel,

- screw.

Most of the space in the house is occupied by a single-flight staircase, while it is the single-flight and double-flight stairs that are most convenient for movement. Screw, takes up less space, but at the same time it is not very convenient and practical, and its daily use can cause a number of inconveniences.

How stairs are arranged

Marching

Any staircase, no matter what its design and size, has common elements.

So, in any case, she has:

- marches,

- steps,

- railings,

- balusters,

- playgrounds.

The staircase is located between the upper and lower platforms and is the main element, and the convenience of using the entire staircase depends on the correctness of its calculation and manufacture.

The device of flights of stairs is reduced to the correct calculation of the angle of its inclination, the length of the bowstring or stringer, the number of steps and their dimensions, as well as the method of fastening the entire structure.

It is recommended to do no more than 17 steps on one march, but 12 are considered the optimal number. Moreover, the height of each of them should not exceed 19 cm, and the width of the staircase for the most comfortable movement should not be less than 80 cm.

In addition to marches, fencing elements are an important component. They are necessary for the safety of movement of people, and also have to perform the function of increasing comfort, since, relying on the railing, it is much easier not only to ascend, but also to descend.

In addition, the device of the handrail on the stairs should not only be effective and reliable, but also have an aesthetic function, since the effect produced on people by the appearance of the entire structure depends on the design of the handrail and balusters. But do not forget about the direct purpose of the railings, therefore, their correct and reliable installation is very important.

Railings are fixed with pillars and balusters. Pillars are installed at the beginning and end of the march, and balusters are placed in between. The main difference is the fact that there can be only two pillars on one flight of stairs, but the balusters can be either 1 or 2, or 10, and sometimes 15.

Attention! For a more reliable arrangement of stairs, it is recommended to mount the fasteners in the wall during its construction. If the staircase is built into an already finished house, it is fraught with rather large destruction and loss of reliability.

Screw

The device of spiral staircases can be described as follows:

- Column,

- steps,

- railings,

- balusters.

First of all, you need to make a reliable base for the column. For this, a concrete block reinforced with metal rods is poured on the ground floor. In most cases, the base has a square shape with sides of 80 cm and a thickness of about 50 cm. The diameter of the reinforcement should not be less than 10-14 mm.

To the column, which in most cases is a metal pipe with a diameter of 100 mm to 150 mm, step pads are welded in a circle with a certain pitch. There are screw structures that do not have a central axis, but due to the complexity of calculations and production work, they are difficult for self-production.

These parameters are more than enough for the ladder to be securely fixed.

The device of a spiral staircase does not allow the use of a riser, since it will only complicate the ascent by reducing the area of the step. The steps themselves are wedge-shaped with a narrow part at the point of attachment to the column.

The following values are considered the optimal dimensions of steps for spiral staircases:

- staircase width 65-80 cm;

- the width of the step at the column is 10-15 cm;

- the widest part of the step is 25-30 cm;

- the thickness of the step is at least 4 cm.

- step platforms are made of metal corners and welded to the column,

- the distance between them in height should be from 16 cm to 19 cm,

- along the axis, each new step must begin where the previous one ended.

Thus, it turns out that there should be about 15-19 steps to climb to the second floor.

With such parameters, the operation of a spiral staircase will be most convenient, but still this type of construction has certain limitations. For example, it is impossible to lift bulky things along it, and ascent and descent require a certain skill and expenditure of energy.

Monolithic stairs

The most durable structures are obtained only if reinforced concrete is used as the main material.

In principle, the construction of a monolithic staircase is more complicated than an ordinary wooden staircase, but the use of concrete has several advantages:

- maximum strength and durability;

- the ability to manufacture stairs of any type, configuration and type;

- fire resistance;

- a monolithic base can be finished with any materials.

Among the shortcomings, one can single out the large weight and the problematicness of dismantling in the event of redevelopment of the house.

The manufacturing instruction says that at the first stage it is necessary to make a formwork that will completely repeat the appearance of the future staircase. You can make it one or two steps, with winding steps or a landing. It all depends only on your desire and the area of the house allotted for the construction of the stairs.

The device of monolithic stairs is not fundamentally different from any other reinforced concrete structures. All marches and platforms are reinforced with metal rods with a diameter of 10-14 mm, after which the structure is poured with concrete, the steps are carefully leveled, and after 14 days, the formwork is removed. The ladder can be fully used for its intended purpose 3 weeks after its filling.

Stairs in cottages and mansard houses

Small cottage-type houses with an attic, as a rule, are equipped with non-bulky stairs. In most cases, the construction of staircases in cottages differs only in the material used.

It can be either wood or a metal frame, which is then sheathed with decorative material. For the rest, these are, as a rule, two-flight staircases, for which it is enough to allocate a platform with a size of 2x2m.

The best material for making attic stairs is undoubtedly wood. Moreover, if you are on a limited budget, it is not necessary to use oak or beech for this. Even varnished pine boards will faithfully serve you for more than a dozen years.

The device of the stairs to the attic practically does not differ from ordinary wooden ones. Depending on the lifting height, you can choose a one- or two-flight, half-pivot structure.

If the dimensions of the opening allow, then one or more stringers made of boards are installed, after which they are sheathed with steps and risers. Balusters and railings are installed last.

Outdoor metal stairs

In the event that it is necessary to install a staircase outside the house, there is no better material than metal. The device of a metal staircase is perhaps the simplest of all possible designs.

Ladder construction:

- supporting beams of the frame made of a profile pipe with a size of 100x50 mm;

- from a corner 35x35 mm vertical and horizontal steps are welded to the profile. Their height and length are calculated in the same way as for any other type of stairs. The most optimal degree sizes are determined by the following parameters:

- the width of the steps is 85-90 cm;

- depth 27-28 cm;

- height 17-18 cm.

With such dimensions of steps with an angle of inclination within 35-45 degrees, the movement on such a ladder will be as comfortable as possible.

After the frame is welded and installed on metal supports, steps and platforms are sheathed with iron sheets and covered with several layers of paint, which will protect the metal from corrosion.

Conclusion

When designing stairs, one must not forget that they can be not only a transition from floor to floor, but also a decoration of the room. In the video presented in this article, you will find additional information on this topic.