In the modern world, many are wondering how to make a staircase to the second floor yourself, because the presence of the upper level is not uncommon these days. At the same time, I want to create a structure that will have a moderate cost and originality, and in the case of an order in a specialized company, this is difficult to achieve.

Although the construction of such a structure is considered not so easy, it is quite possible to carry it out with your own hands.

Preliminary calculations

When determining the bearing capacity, all structural elements of the system are divided into single-span and cantilever beams, the number of which is calculated using special formulas. Due to the presence of dynamic loads, quite serious requirements are imposed on the rigidity of the bearing parts.

Thus, the calculation takes into account the dead weight of the structure and temporary loads from 300 kg per square meter.

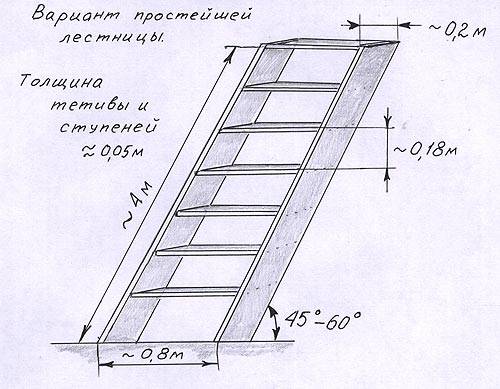

- The width of the flight of stairs for easy passage of one person should be at least 80 cm.

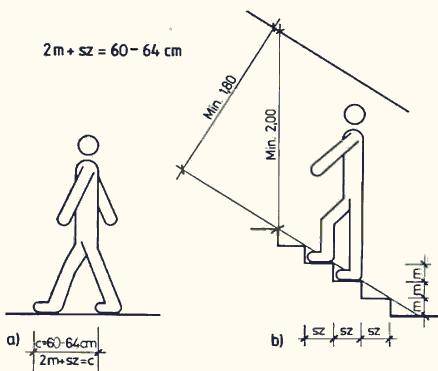

- The size of the tread is chosen so that the leg can rest with a full foot... Typically a distance of 200 to 320 mm is ideal for this. With other indicators, people may go astray.

- The optimum lifting height is 150 mm... Low steps can significantly lengthen the system, making it compact, and too high can make movement inconvenient.

- The overhang of the tread over the previous rise should not exceed 50 mm, otherwise there is a risk of getting caught by the foot... A similar protrusion is usually made when it is not possible to increase the width of the step in another way.

- The most convenient angles of the structure are in the range from 23 to 37 degrees.... The occupied area largely depends on this factor.

- The number of steps is determined by the height of the floor and the slope of the structure, but it is recommended to make from 3 to 18 pieces.

Note!

Having familiarized yourself with the above dimensions, you can easily understand how to correctly make a staircase to the second floor.

However, in addition to theoretical aspects, detailed manufacturing information will be required.

Design options

Most often, when building an interfloor system, two materials are used: wood and metal. Despite the final choice, several types of stairs can be distinguished, based on the design features. Both metal and wood products have a similar structure, but different methods of fastening the elements.

Systems on stringers

The supporting elements are wooden bars or metal beams with special cutouts for the steps of the stairs. Of course, everyone decides for himself how best to make a staircase to the second floor, but thanks to the support racks, this structure acquires visual compactness and extraordinary lightness.

If necessary, it can be decorated with impressive decorative components.

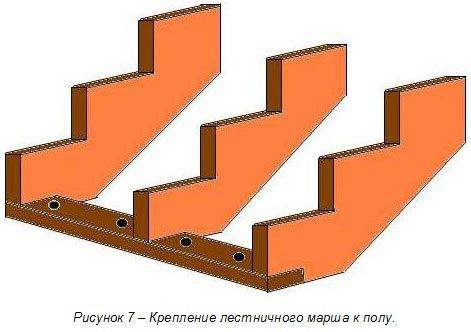

- From a bar with a section of 60 × 250 mm, cutouts are made for the steps from the side of the end part, so that a kind of kerchiefs are obtained. It is advisable to completely treat wooden parts with protective compounds.

- Ready-made stringers are installed in the opening area using self-tapping screws or ordinary nails. In some cases, reinforcement can help provide metal parts.

- From the boards of the required thickness, parts are cut to close the rises from the horizontal and vertical sides, or fragments of metal are prepared.

- The elements are fastened in any of the many ways, while it is better to install the perpendicular planks first. It is advisable to cover them after.

- Railings are made, consisting of separate posts and handrails. Support balusters are made more massive in contrast to intermediate counterparts.

Addition!

Above, it was outlined how to make a staircase to the second floor using kosour.

If this option suits someone, then it can be realized using wood, metal and other materials.

Structures on bowstrings

Support beams are used for the device, but unlike the previous analogue, the cutouts for the steps are made from the inside. That is, the ends of the ascents are completely or partially hidden by the inclined bar.

In order to avoid skewing of the structure, special attention must be paid to the accuracy of the grooves made.

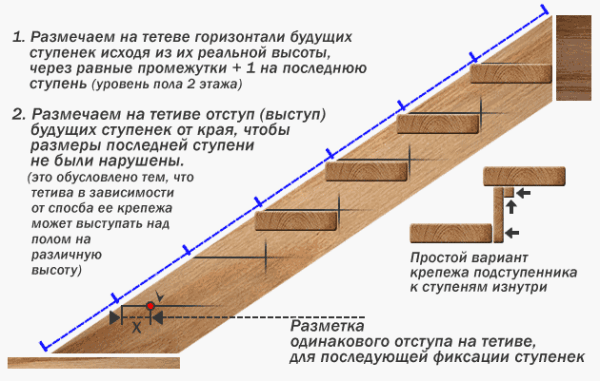

- Two bowstrings are cut to size. To do this, they must be installed in the place where the new staircase will be located.

- The location of the steps is determined, after which special grooves are cut out for horizontal elements.

- Side holes are drilled for the tie rods, which will not allow the support legs to disperse.

- The second bowstring is pre-installed, but not completely fixed, after which the boards for the steps are inserted.

- After completing all the actions indicated in the previous paragraph, use a wooden hammer to knock out the entire support post.

- The inclined elements are pulled together, for which washers and nuts are placed on the studs.

- The remaining holes are closed with special plastic caps, which must match the color of the tree species.

Attention!

Above, it was described how to make a wooden staircase to the second floor, however, in the case of metal elements, special supports for steps can be welded to the stair stringer.

Analogs on bolts

Initially, such structures were used when it was required to build a convenient ascent to the attic or descent to the basement. However, gradually they began to be actively used in residential buildings, due to their originality and aesthetics.

Various materials make it possible to choose the appearance of the system: elite wood species, metal, stone and glass.

- First, rubber gaskets are installed in the side plane of the room, after which large bolts (bolts) are inserted, to which the steps will be fastened.

- After completing the marking, the installation of the support balusters of the stairs begins, which are fixed as reliably as possible. The fence posts are attached to the ceiling with special metal brackets.

- After carrying out the work associated with the installation of balusters, the handrails and bolts are assembled, which combine the fence posts. The leading edge of the higher step rests on the back of the lower riser.

Note!

The above is information on how to make a staircase to the 2nd floor yourself using bolts.

In the process of work, there is no need to use any scaffolding, since the flight of stairs is going from bottom to top.

General recommendations

- When constructing structures equipped with winder steps, the geometry of the stringers is different, therefore, the cutouts must be marked according to the size of each rise.

- If the kerchiefs turn out to be rather deep and to some extent weaken the system, then it is advisable to increase their number. For example, make three or four support legs with cutouts.

- It is better to fix the steps to the racks themselves in a hidden way, then the aesthetic component will not suffer. You can also improve the appearance by using carved elements.

Important!

The presented instructions should help you choose the best staircase design for a residential building, having previously looked at the manufacturing technology.

Finally

Viewing the thematic video in this article will allow you to understand this topic as accurately as possible, so it is recommended that you familiarize yourself with it after studying the text information.In order for the final cost of the structure to remain minimal, it is necessary not only to independently perform the work, but also to choose the right materials.

yes, my husband’s hands would grow from the right place. it would be not bad to save money on the masters. damn it is so offensive, you find articles on the Internet that all this is not so difficult and it could not be so expensive if someone showed a desire to do something himself ...