Owners of summer cottages and private houses often have to make something with their own hands. Many people start to like it so much that over time it becomes necessary to build something really serious. For example, turn a nondescript attic into an attic living space.

It's time to think about such a question as making stairs with your own hands. We will talk about this in this article.

Construction of stairs

Building a staircase is not an easy task, it will require skill and some preparation from you.

Of course, if we are not talking about a simple staircase to the basement or to the attic, the price of which will not exceed 500 rubles.

Know! The construction of a staircase in a house, first of all, implies obtaining a safe and reliable structure at the exit - along which children will run in the future, as well as elderly people carefully descend.

If you are confident in your abilities and take responsibility for the benign manufacture of such a complex design, the instructions will certainly be useful to you.

Choice of design

The idea of \ u200b \ u200bthe construction of a staircase should begin with the choice of material and construction. More often than usual, such a popular material as wood is chosen for the manufacture of this structure.

A wooden ladder is easier make at home than, for example, an aluminum step ladder. The latter will be more reliable and easier to order from a manufacturer that specializes not only in production, but also in assembly.

So, structurally, staircase structures can be divided into two main categories:

- screw;

- marching.

For the manufacture of a spiral staircase at home, we do not recommend you undertake. This will require you to:

- complex calculations;

- professional provision of maximum stability of the rack (bearing) throughout the entire service life;

- reliable fastening of the steps.

Marching stairs are divided into:

- single-marching;

- two-march (it depends on the layout of the premises).

In addition, on:

- straight;

- swivel.

Beginner craftsmen should opt for the construction of a direct structure. They are easy to manufacture and, at the same time, reliable. Nevertheless, if there are more than ten steps, it is recommended to divide the staircase with a platform.

In this case, the structure of the staircase will already be rotatable. In accordance with the pivoting angle, structures are also divided into:

- quarter-turn (90º - angle of rotation);

- semi-turn (180º of rotation);

- circular (360º rotation - which is already a conventional screw design).

Wooden ladder

Making a ladder with your own hands - a great alternative for novice craftsmen. This construction is quite simple.

To begin with, you need to prepare bars from coniferous trees, best of all from pine. For a ladder of three meters in height, you will need bars with a cross section of 50 x 40 mm, but for a five meter high - 80 x 40.

Its useful to note! Thick bars make the structure very heavy, and too thin - make it weaker. Try to find the best option. Bars of wood must be free of knots.

Let's see how to directly make the attached model itself:

- first we cut off two bowstrings, adjusting them to the size of the desired section;

- now we round them and lay them out on the floor in such a way that the upper part is slightly narrower than the lower one (the distance between the two centers of these two bowstrings: bottom 40 cm, top - 30 cm);

- further, we fix the structure with temporary slats;

- the steps should be 35 x 40 mm, the corners are rounded as on the bowstrings;

- the distance between the steps is no more than 25 - 30 cm;

- steps and bowstrings are best numbered at both ends to match when assembling;

- we cut out the thorns at the ends of the steps in order to then insert them into the necessary sockets on the bowstrings (a thorn 40 mm in length, 30x15 mm in section);

- we remove the temporary strips and prepare the grooves for the thorns on the bowstrings - according to the numbers affixed in advance;

- we insert the thorns as tightly as possible, but not allowing the tree to split on the bowstrings;

- we prepare tie rods (with a diameter of 8 mm) with threads at the ends - their number depends on the total length of the structure and they are located no further than 200 cm from each other. We place the extreme studs along the upper and lower steps (there will be 3 of them in a 3-meter staircase, and 4 in a 5-meter staircase);

- each spike is greased with glue and, starting from the top, we insert according to the step numbers on the first string, then on the other;

- after assembly, holes are drilled for the studs, the ladder is tightened with nuts;

- we sharpen the lower ends of the bowstrings so that they can then be upholstered with metal nozzles;

- the next day we sand the ladder and cover it twice with linseed oil (every other day).

The main elements of marching wooden stairs

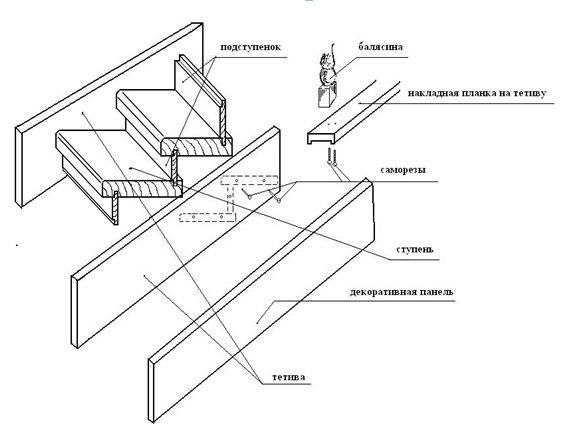

Such structures are composed of the elements shown in the figure below.

Stair steps

The standard version of the stage assumes the following parameters:

- step width - 30 cm;

- length - from 80 to 120 cm;

- thickness - standard option - 30-40 mm (20 mm for facing or in the case of concrete risers).

In the event that the manufacture of risers is not planned, then the step itself should be no more than a meter in length, with a thickness of at least 25 mm, but with an additional bar that will give rigidity to the entire structure.

Advice! Such an option is also possible: with a step length of 100 cm and a thickness of 30 mm, the stringers move towards the center, which ultimately will allow to distribute the load more evenly.

Risers

The riser is not always an obligatory element of any design. Nevertheless, if it is nevertheless provided, we do not recommend using a sawlog for its manufacture. We recommend using only the material that has increased strength.

Bowstring

In structures made of concrete and aluminum, this element is not used at all. For a wooden staircase, a bowstring - this element is required, its dimensions are directly related to the design of the entire structure.

In particular, the straight model must be fitted with a maximum bowstring size. The building materials market is widely represented by bowstrings of standard dimensions:

- width - 280 - 350 mm;

- length - 300 - 485 cm;

- thickness - 3.8 - 4 cm.

Support posts

For fencing, as well as giving rigidity to the entire structure, support pillars are used. They are mainly produced by turning.

There are standard sizes for this element:

- cross-section - in the range from 70 by 70 mm to 120 by 120 mm;

- height - 100 - 130 cm.

Props, handrails and balusters

It is a known fact that balusters are designed to protect a person from falling, therefore, the distance between the centers of these elements should not be more than 15 cm.

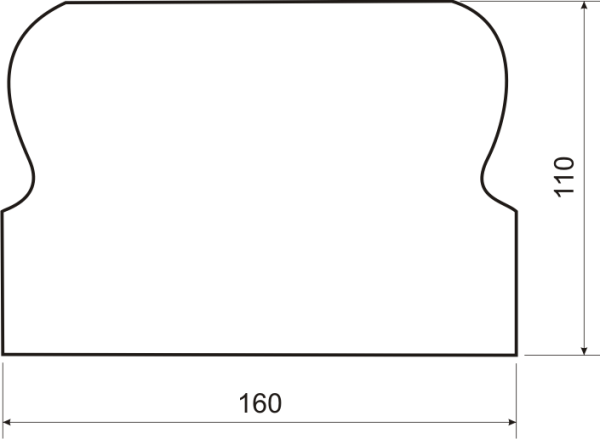

Balusters are made in various design styles, and their dimensional characteristics range from:

- in thickness from 30 to 80 mm;

- in height - from 800 to 900 mm.

You can buy balusters already made, or you can start producing them yourself.This requires special tools and equipment.

With the help of a support rail, the baluster is fixed from below. This element is used when installing a baluster, the dimensions of which overlap the width of the bowstring: the sub-rail is used as an expander.

This complete set is completed by a handrail. The more convenient this element is, the more comfortable all members of your family will feel, going up and down the stairs you have built from day to day.

<h2Reinforced concrete stairs - a beautiful and practical architectural element "href =" https://flwn.imadeself.com/33/betonnye/40-zhelezobetonnye-lestnicy "> about the advantages of reinforced concrete stairs).

It is worth starting to make sure that making a staircase is a completely simple process!