Historically, it so happened that mankind was required to periodically rise to a certain height. In the beginning, these were tree trunks, where the branches acted as handrails. After that, people hoisted themselves to create devices from longitudinal and transverse beams. This method has survived to this day and is actively used.

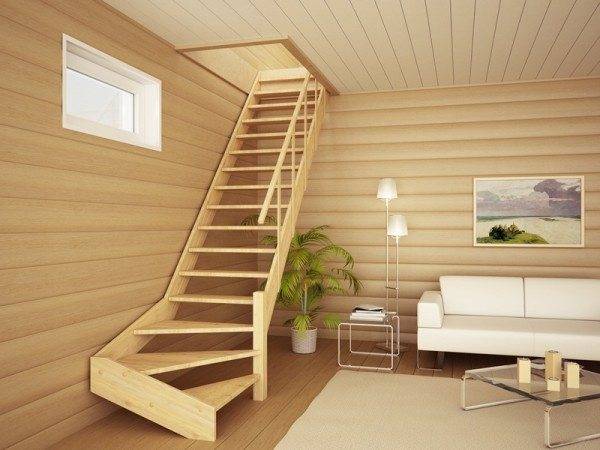

Nowadays, stairs from the category of necessary things began to resemble works of art more, which is confirmed by various designs in private households. In this case, construction is not limited to one floor, but combines an attic or several floors, a basement and other premises, between which it is necessary to move quickly and safely.

In addition, there are many owners who prefer making wooden stairs with their own hands. They become interior decoration, emphasizing their taste and individual preferences.

It should be noted that in many cases it is not always possible to establish standard designs. Therefore, when designing, architects devote a lot of time to this issue.

If you have some of the makings of a carpenter or desire to get them, you can make a ladder yourself. Thus, the design will become not only convenient and safe, but also the only one in the world. You can always visually show your friends or guests your talent, which they will surely appreciate.

In addition, making a wooden staircase with your own hands or repairing an old staircase will bring moral satisfaction to many, especially to those who like to independently achieve their goals. Moreover, today it is not difficult to find materials and tools for this.

Terms

Before starting work, it is necessary to study the terms that will be useful in the future.

Then, leafing through any literature, you can easily understand what is at stake.

- Flight of stairs - an inclined part of the staircase with steps.

- Tread - horizontal step platform. Its width is the distance between the edges of the steps.

- Riser - the vertical part of the step. Its height is the distance between two adjacent risers.

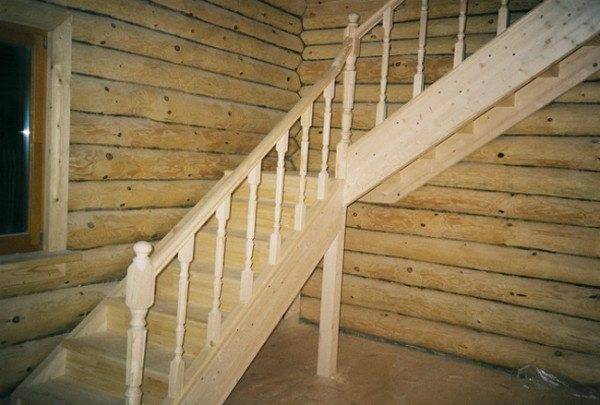

- Railings - stair railings.

- Handrail - the horizontal part of the railing.

- Rack - the vertical part of the railing. At the beginning and end of the march, support balusters are installed.

- Balustrade - railings from balusters and handrails.

- Stair slope - the ratio of the riser to the step.

- Bowstring - the bearing part of the flight of stairs, to which the steps are attached to the side.

- Kosour - the bearing part, to which the steps are fixed from above.

- Handrail height - distance from the horizontal surface of the step to the top of the railing.

Back in the 15th century, Henry Wotton formulated the main part of the rules for the manufacture of stairs, which are still used by modern builders. Among them are good lighting of the steps so as not to stumble or bump, sufficient headroom, wide steps and a slight incline.

Material

When creating stairs, designers use mainly reinforced concrete, metal or wood. The first and second are used mainly in industry, production, standard construction, the third - in private housing construction.

Wood can be easily processed with simple and affordable tools. The details of the structure are effortlessly connected to each other. With the help of paints and varnishes, it becomes possible to create a good decorative effect.

When choosing, for example, a staircase made of oak and softwood, it should be borne in mind that a staircase made of hardwood is strong and durable in use. But the price of such a design will be much more expensive.

Therefore, most of the stairs are made of coniferous trees. For example, a bowstring and a riser are made from larch, fir, spruce and pine, but on the steps they showed themselves not in the best form, as they quickly fell into disrepair due to the softness of the structure.

Advice: the boards should be free of knots or with a minimum amount, with a clearly visible structure.

Then the staircase after decoration will be able to fit well into the interior of the house.

The wood must be dry (the required moisture content is 8-20%), which can be determined using an electric moisture meter. For not having it, some use other methods, for example, crush shavings. If it crumbles, then the humidity is normal, if it wrinkles, you will have to dry the material. But you shouldn't be guided by them.

Tool

Before starting work, preliminary preparation should be made. In particular, put the tools in order.

You will need:

- Axe.

- Hammer.

- Hacksaw for wood, bow saw.

- Plane.

- A set of chisels and a chisel.

- A set of screwdrivers or screwdriver.

The cutting edges must be sharpened correctly.

In addition, a marking tool is also required:

- Square, goniometer.

- Roulette.

- Plumb line or level.

Recommendations

The stairs should be installed in a room in which, in addition to the first floor, rooms located above are used temporarily or permanently. It is necessary to install good lighting above it, especially above the first and last steps.

In order to feel comfortable on the stairs, the width of the staircase should be made from 0.8-1 m. Handrails should be equipped with structures that have more than three steps.

If windows are adjacent to the stairs, they should be securely fenced off. The height of the riser should not exceed 20 cm, and the width of the tread should not exceed 25 cm. The angle of inclination of the structure should not exceed 38˚, in some cases it can be up to 45˚. The use of slippery materials for the steps is not permissible, otherwise anti-slip pads should be installed on them.

Ladder with bowstrings

The design feature is that the steps are located between two boards 60-80 mm thick, the ends of which rest against the floor in the lower part and in the interfloor overlap in the upper part. For reliability, they are fixed with wedges, screws, bolts.

There are two connection options - cutting into a bowstring or into wooden blocks. In this case, the main boards are connected to each other with a metal pin with a thread, at the ends of which nuts are installed.

The first method is considered more reliable when not only the tread is cut into the bowstring, but also the riser. However, it requires the special precision that the triangular pattern provides. Very often they perform a marching wooden staircase without risers.

Ladder

It can be portable or docked. There are many types of them, but you can find out how to make a wooden staircase with your own hands below.

For this, two wooden beams 35x50 mm are taken. In them, grooves with a depth of about 2 cm are cut at a distance of 20-30 mm, but they can also be through. The beams are made of a bar of 30x40 mm and a length of 40 cm, at the ends of which spikes are made.

It should be remembered that landing in the bowstring will occur in an interference fit. In this case, the crossbeams should be inserted into the grooves halfway, and then, tapping with a mallet, fully install them in place.

The joints must be pre-treated with glue. The method is reliable, but for additional security, you can fasten the spikes with self-tapping screws. The design flaw is a steep slope, which makes it difficult to deliver goods.

Tip: After assembly, all sharp places on the stairs must be sanded with sandpaper.

Duck step

This type of wooden staircase is an improved type attachment option.

The instructions below allow you to do this:

- Make the sidewalls (ladder bowstrings). To do this, take two well-dried boards 3 m long and 60x400 mm in size.

- Make steps from a 40x300 mm board in the wide part and 150 mm in the narrow one.

- Secure the steps with 10x45mm rounded hardwood dowels.

- Drill 3 holes on the wide side and 2 on the narrow side.

- Lubricate the spikes and holes with synthetic or wood glue and connect the steps with a string.

- Take threaded metal pins on both sides and use nuts to make at least 2 ties.

- Attach the posts and railings directly to the string.

Tip: use the duck step staircase for rooms with a ceiling height of 2.75 m.

Output

You can make a wooden staircase yourself, but for this you need to have some carpentry skills. In the video presented in this article, you will find more information on this topic.

Regarding the ladder, I slightly disagree with the thickness of the bar 35 ″ 50mm. This size can be individual for most, but not for every person, as well as the steps of the stairs should be free of knots.