What can be the posts for wooden stairs? What are they needed for? What other functional and decorative elements are present in the construction of stairs?

What materials and what size can they be? Let's try to answer these questions.

Terminology

First, let's define the names. Staircase construction, like many other areas of construction, uses a fair amount of specific terms.

A spiral staircase is a structure with radial steps of a triangular or trapezoidal shape, resting on a central column or pillar. The main advantage of the structure is its compactness: it takes up a minimum of the area of the room and does not require an excessively elongated opening in the ceiling.

There are quite a few disadvantages:

- Due to the shape and traditionally small width of the steps, only one person can go up or down at a time.

- Transportation of furniture and other bulky goods is extremely difficult. For example, to bring a sheet of drywall 1.2x2.5 meters in size along a spiral staircase with a step width of about a meter is simply unrealistic.

- For people with reduced mobility, such a ladder can be an insurmountable obstacle.

In addition: the calculation of the structure is also quite complicated. You have to accurately calculate the width, height and position of the step. Otherwise, we risk getting an exorbitantly large or too small drop when entering the second floor.

The flight staircase is much simpler in design, stronger and more convenient in operation. There can be several marches; they can be connected by platforms or so-called winders. Two marches can be oriented relative to each other at any angle up to 180 degrees: everything is determined by the shape of the room.

The names of some structural elements also need clarification.

- Kosour - a bearing beam on which the steps rest from above.

- Bowstring differs from the kosour in that the steps are attached to it not from above, but from the inside by means of grooves or holes. It is clear that the grooves weaken the structure, so the bowstring requires a greater margin of safety compared to the stringer.

- Tread - horizontal step element.

- Riser - a vertical element connecting two treads.

Useful: the riser is optional; however, it stiffens the structure by supporting the tread.

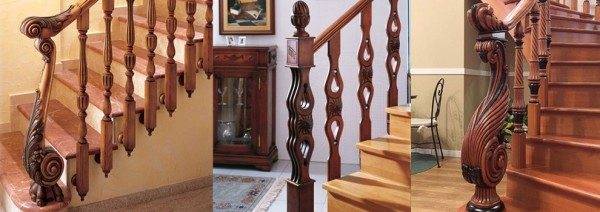

- Baluster - vertical element of the handrail, post. Usually it carries not only a functional, but also a decorative load.

- Balustrade - fencing of the staircase or balcony overhanging the staircase.

- Support pillar - a vertical load-bearing element that provides support for the landing, the entire spiral staircase or run-in steps. It often rises above the steps and is a support for the handrail.

- Finally, the entry stair post usually combines the functions of the supporting element of the railings and, often, the staircase itself, with purely decorative functions. In a broader sense, it is simply a massive baluster decorated with carvings or additional decorative elements.

Materials and options

Load-bearing elements

Since the pillar appears in the name, let's start with it and, in general, with the supporting elements of the structure.

The only strict requirement for the wood of the support pillar is the absence of cross-layer and large knots, which affect the strength of the structure.For the rest - a minimum of restrictions: support posts for stairs can be made of oak, beech, ash, larch, pine, spruce and other species.

It is clear that the price of a pine pillar will be incomparable with the cost of a product made of noble wood species; the owner will have to decide what is more important for him - economy or aesthetics.

Unlike purely functional support ones, staircase posts are usually made of rocks with a beautiful texture.

Weight options:

- Smooth posts are the cheapest. Turning and grinding are not time consuming.

- Turned products are noticeably more expensive: they are already piece goods that are made by hand, albeit using the same lathe.

- Finally, the top of the sophistication is carved products. A carver can spend up to a month to make a pillar. The pillars can be symmetrical, complex artistic compositions, or even full-fledged wooden sculptures.

Note! On sale it is easy to find curly poles, balusters and handrails made of pressed wood impregnated with protective and strengthening compounds. Their production is noticeably more technological, which has a positive effect on the cost; the material is more durable and much stronger than ordinary wood of the corresponding species. The only drawback is the limited choice of product shapes.

The requirements for the material of stringers and bowstrings are no different from the requirements for posts: any high-quality wood without defects is used for them.

Fencing

Balusters and handrails are products in which decorative qualities are usually more important than functionality. In fact, with a baluster pitch of 15-20 centimeters, it is not difficult to provide strength with respect to horizontal load when using any type of wood. The beautiful texture of the handrail will inevitably draw attention to itself.

Traditionally, handrails and balustrades are made of ash, which has a very beautiful texture pattern with outstanding strength and durability. However, after impregnation with an antiseptic and varnishing, pine railings are hardly inferior to ash ones in terms of service life.

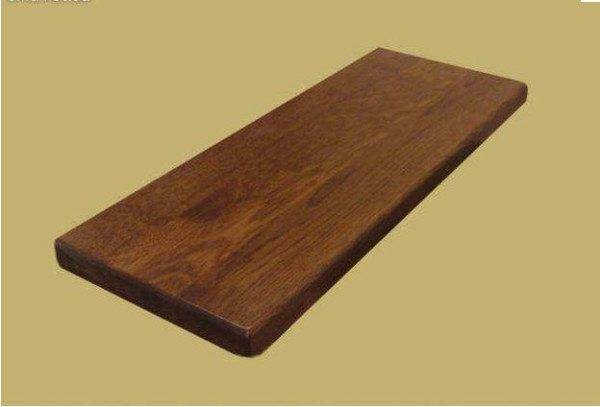

Steps

Unlike other structural elements, they are subject to mechanical wear. Note that even along the internal interfloor staircases, the inhabitants of the house do not always move in slippers: stilettos and hard heels are also present.

Hence the instruction for the selection of wood species:

- Exceptionally dense and durable oak, ash and maple are most preferred.

- Larch resists rotting well and is strong enough for our purposes; at the same time, it is noticeably cheaper than wood of noble species.

- Pine and spruce are budget materials with limited mechanical strength. A dense varnish coating can partially protect them from numerous dents and scratches. Parquet polyurethane varnish is best suited for its role.

It is applied in 5-7 layers with complete drying of each of them. At least after applying the first layer, the surface is sanded with zero-grade emery paper: the varnish layer raises the pile, which makes the surface rough.

By the way, to achieve maximum uniformity of the coating, it is better to sand all layers except the last one.

All paintwork is carried out after a thorough cleaning of dust.

Dimensions (edit)

What sizes of the main elements should you focus on when making a wooden staircase with your own hands?

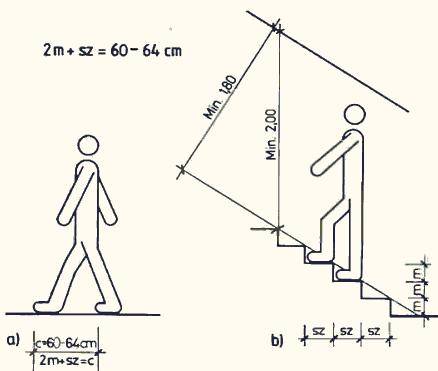

- The optimal step size is 300x150 millimeters (width / height). In this case, we get a quite convenient staircase slope of 1: 2. A height range of 150-200 millimeters with a width of 260-350 millimeters is considered comfortable.

On a steep incline, older people may have trouble getting up; if the width of the step is too low, it is easy to fall from it during descent, and even during the ascent, the legs will be in continuous tension.

- The comfortable ratio of step height and width is related to human anatomy. The most convenient step is the sum of the width and doubled height of which is equal to the step length.

For reference: the stride length of a person of average height is 60-64 cm.

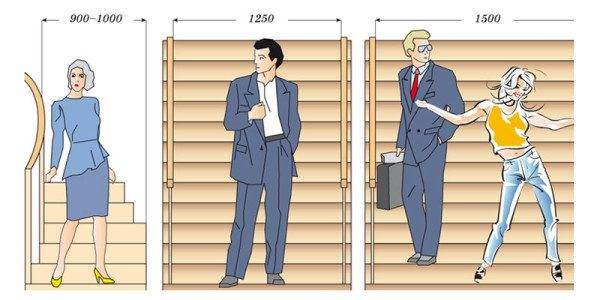

- The optimal height of handrails and balustrades is 900 - 1000 millimeters. At the same time, according to the current SNiP, the fence must withstand a horizontal load of 100 kgf.

- The same SNiP recommend, for safety reasons, to install balusters with a step of 15 centimeters.

- The standard section of curly balusters is 45x45 millimeters, lead-in posts - from 80x80 to 100x100 millimeters. The support post for the stairs usually has the same section.

- Kosoura and bowstrings are usually made from a board 50-70 mm thick and 250-300 mm wide. To ensure maximum rigidity of the structure, it is installed vertically.

- The minimum width of the flight staircase, designed for the passage of one person - 900 mm, for two - 1200 (optimal - 1500) mm. The typical width of the spiral staircase from the center column axis to the edge of the step is 1000 - 1100 mm.

Output

We got acquainted, albeit very superficially, with the basics of designing wooden stairs. In the video presented in this article, you will find additional information on this topic.

Good luck in construction!