In cottages and houses with an attic, the staircase is an extremely important structure. Moreover, it plays not only the role of a functional element of the building, but also an interior decoration. To make the structure look attractive, the material from which it is made is especially important, and in this regard, an ash staircase looks the most advantageous.

Ash features

In addition to appearance, characteristics such as depend on the material of construction:

- Environmental friendliness;

- Lifetime;

- Labor intensity of manufacturing, etc.

For these indicators, ash is also a very attractive building material. In addition, due to the natural design with a pronounced structure, ash wooden staircases do not need special decor. These stairs are beautiful in themselves. It is enough just to cover the structure with colorless varnish, and it will decorate the whole interior.

The advantages of this wood include:

- High strength;

- Flexibility;

- Impact strength;

- Plastic;

- Ease of sanding.

Ash in many of its properties is not inferior even to oak. It is just as strong and hard, besides the wood is very resistant to deformation. Therefore, among connoisseurs of beauty, builders and home craftsmen, ash is deservedly loved.

This type of wood will be especially the right decision if you want to build a structure with an unusual shape, since ash is able to bend and at the same time maintain its strength. Thanks to this property of the material, almost any architectural idea can be realized. In particular, ash is often used to create curved handrails or for the bowstring of turning stairs.

Finally, I must say about one more important advantage of ash - it's environmental friendliness. Even after several years of operation, wood does not emit any substances that could cause allergies or somehow adversely affect health.

Note! With all these advantages, the price of an ash staircase will be 30 percent lowerthan the same oak staircase.

A minor drawback of this wood is a certain color variation from dark to light tones. However, with careful selection of blanks, it can be easily eliminated. And with color tinting, it doesn't matter at all.

Making stairs

The technology for building a staircase from ash does not differ from the manufacture of products from other materials, with the exception of the possibility of bending some elements, as mentioned above. If you want to create a structure with your own hands, then the small instructions below will certainly be useful.

Staircase project

First of all, it is necessary to decide on the type of construction, since there are a great many of them:

- Marching with a staircase (such designs are both single- and multi-march).

- Marching run-in;

- Screw;

- Duck Walk.

In addition, they differ in the type of device:

- Bowstring

- Based on kosour

Also common are combined structures with a metal frame and sheathed with wood. Next, we will look at how to make a ladder made entirely of ash, since you do not have to resort to welding for this.

As a rule, one of the main requirements for a home staircase is compactness. A spiral staircase takes up little space, but it is very difficult to manufacture. The Duck Walk ladder also takes up little space, but it is less comfortable to use.

Therefore, the best option would be a marching staircase, and to save space, instead of a platform, you can make run-in steps. Then it remains only to choose the type of construction - on kosoura or on two bowstrings. It all depends on your taste.

It should be noted that the bowstring will always be in sight, and the stringers are hidden. If you plan to make winding steps, then it is better to give preference to the second type.

Payment

It will not be difficult to make the necessary structural calculations, knowing the basic requirements:

- The tread width must be at least 200 mm and not more than 300 mm;

- The optimum riser height is 150 mm;

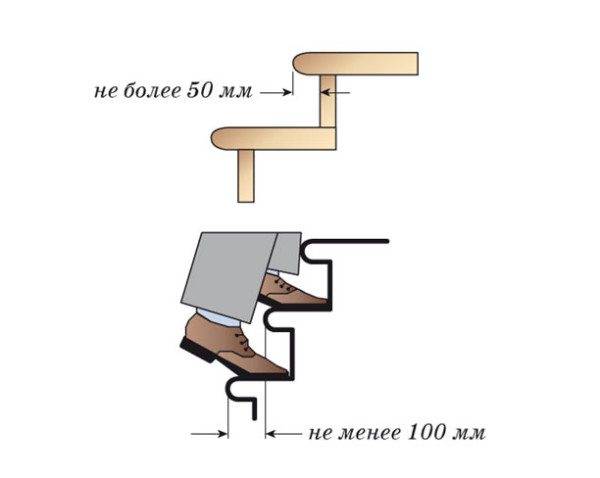

- The height of the overhang of the tread over the lower step should be no more than 50 mm;

- The minimum width of the winder at the narrowest point must be at least 100 mm.

- The optimal angle of inclination of the structure lies in the range of 23 - 37 degrees. If you need to make a steeper slope, you will have to design a ladder of the "Duck Walk" type.

- The optimal march width is 90-100 cm.

Based on these data, it will not be difficult to complete the drawing and the calculation of the structure.

Instruments

To make an ash staircase with your own hands, you must have a certain set of tools:

- A circular saw;

- Belt sander;

- Manual router with a set of cutters;

- Jigsaw;

- Electric drill with set;

- Hammer;

- Plane;

- Hand saw;

- Screwdriver;

- Building level.

If all this tool is available in a complete set, then the manufacture of the structure will take a minimum of time and effort.

Manufacturing of structural elements and installation

First of all, it is necessary to make supporting elements, in our case - stringers... To do this, you need boards with a width of at least 250 mm and a thickness of at least 40 mm. The workpieces should be accurately marked and stepped cuts should be made on which the steps will be installed.

Advice! The first kosour can be used to mark the second workpiece so that the elements are absolutely identical.

If the staircase has a twist, then you will need four stringers. In this case, it is necessary to install support pillars to which the supporting elements will be attached. Fastening is carried out using self-tapping screws and mounting glue.

When the supporting parts of the structure are installed, it is necessary to make risers with steps and install them on the stringers. After that, the balusters are mounted with studs and the railings are attached to them.

The finished product should be sanded and varnished or painted.

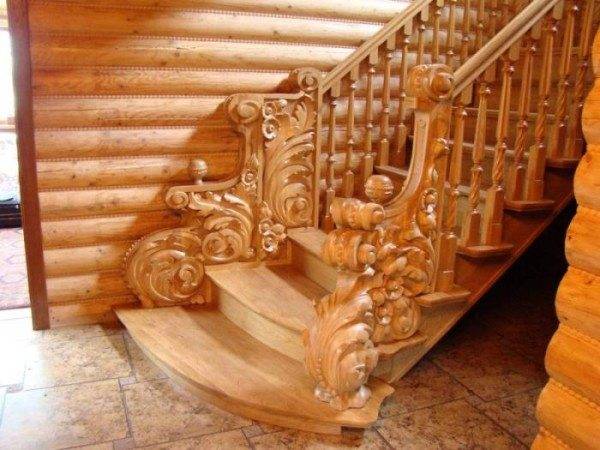

Note! The carvings will make the staircase exclusive and add flavor to the interior of the house.

Output

Ash structure is the most optimal option for an internal staircase for two-story houses. Having the skills to work with wood, it is not difficult to make a ladder yourself, while it will meet all individual requirements.

You can get more information on this topic from the video in this article.

I made a similar staircase from ash in my country house, ash as a material is good from the ratio of price to quality. and it was beautiful and there were no special difficulties.