The staircase is an obligatory element of any building with more than one floor. It is necessary to think about what it will be at the design stage. One of the most common and rational ways of constructing stairs is the use of ready-made flights, which are especially common in civil and industrial construction.

For private cottages, the LS 12 staircase is a more suitable option, with the help of which an individual approach and taking into account the characteristics of a particular house is possible. Using high-quality products made in accordance with GOST 8717.0-84, and observing the rules and sequence of installation, you can mount a capital, safe and beautiful staircase.

Reinforced concrete stair steps

Reinforced concrete stairs - an affordable and rational way to arrange interfloor passages in private housing construction.

The popularity of the use of reinforced concrete steps is explained by several factors:

- A fairly affordable way of laying, which in most cases does not require the use of special equipment. The means of small-scale mechanization, and sometimes the usual manual labor, are quite enough.

- The price for products and for the entire staircase structure as a whole is quite affordable and is one of the most economical options. At the same time, it is possible to arrange staircases of different types - traditional marching, parade marching swinging, in rare cases it is even possible to arrange spiral staircases, of course, subject to technology and strict adherence to design calculations.

- For aesthetic purposes and to match the interior solution, finishing with various building and finishing materials is allowed, the only requirements for which are a high degree of wear resistance and an anti-slip surface.

Steps are used for arranging stair flights inside premises, as well as for external structures on a load-bearing base, which can be used as steel stringers - channel, I-beam.

Manufacturing

Stair steps - elements for the set and installation of a staircase.

These reinforced concrete products are manufactured by the industry by types and sizes:

- with and without embedded parts;

- with and without reinforcing mesh;

- of different lengths, which is indicated by the numerical value, for example, the stairs of the LS 15 have a length of 1500 mm.

Attention! According to GOST, embedded parts are optional only in case of agreement on a project that makes it possible to do without such building parts.

There are steps with a smooth or rough surface. The latter are intended for further finishing, for example, ceramic tiles, marble, etc. Smooth ones do not require special processing, but for their greater strength, a mesh is used, which is located under the surface layer.

The main steps of the march with the LS mark are used simultaneously with the frieze steps for the top and bottom with the corresponding LSV, LSN markings, which should be looked for on the back of the product.

Several types of concrete can be used for production - light, heavy, silicate, but the class of concrete must be at least B15 (for steps with external operation, at least B25). According to the results of technical tests, a load of up to 600 kgf / m² must be withstood for a short time.

For the convenience of installing stairs with different directions of movement (clockwise or counterclockwise), embedded parts can be on the right side, and on the left, or on both sides.

Steel of АI-АIII classes is used as reinforcement, sometimes ВрI wire is used.As additional elements, a flat staircase (LSS) is used for the device of through flights and a stair landing insert (LSP).

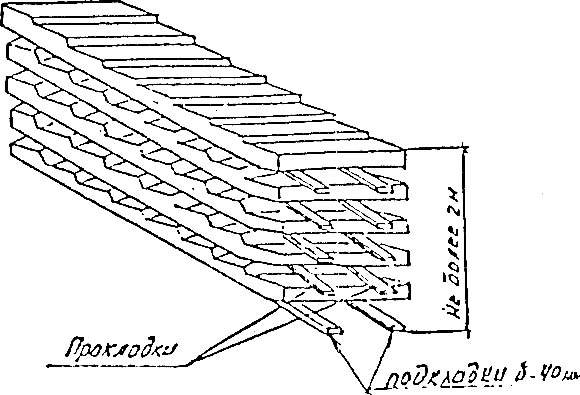

Features of transportation and storage

Particular attention should be paid to the transportation of these products, as well as to their storage at the construction site. The height of the rows should not be higher than five, with the obligatory spacer between the parts. Transportation is allowed only when laying longitudinally to the transport axis. On the construction site, a truck crane should be used for unloading by means of special attachments of packing packs or by means of mounting loops.

Various cracks of more than 0.1 mm are not permissible, and the accuracy and straightness of the dimensions should also be controlled. The deviations should not exceed an average of 2 mm, and in general, the permissible values are in the range from 1 to 5 mm.

The main stages of the construction of reinforced concrete stairs

The device of stairs using type-setting reinforced concrete elements, for example, ladder steps LS 11 11, must be carried out in accordance with all norms and rules.

Before starting work, the following activities should be carried out.

- Preparing the future staircase:

- laying or strengthening the foundation for it and bringing the level to the first site;

- during the reconstruction of the object, it is necessary to dismantle the old structure and prepare for a new staircase.

- The installation of stairs from steps should take place simultaneously with general construction work, and in the case of reconstruction of a building during capital work.

- All load-bearing elements for installation - stringers, beams, channels - are made according to dimensions in advance and are delivered to the site with finished products for installation work:

- all overlays must be welded on the stringers;

- holes are drilled on beams, channels.

- The device of each march should be carried out sequentially, having previously performed the following steps:

- the device of the scaffold;

- marking the levels of interfloor or intermarch sites;

- using a jackhammer, make nests for the beams on which the platforms will be attached;

- install platform beams;

- install stringers or other mounting elements for the stairs, using welding or bolting.

- The steps are laid manually, starting with the lower frieze and with the obligatory correction of the position accuracy using metal wedges.

- In the above sequence, further installation of the remaining marches is carried out, but at the same time:

- be sure to place wooden spacers under the scaffold supports to redistribute the load on the beams;

- lay the running boards;

- fill all the seams between the steps.

- Until the end of the plastering work, temporary protective structures of marches should be used with replacement for permanent ones upon completion of installation.

- You can do the installation work with your own hands, but you will definitely need help. Ideally, the job requires 2-3 fitters, one of whom is a welder.

Code of practice

The installation of stairs should be carried out in compliance with all the requirements of the technological plan, with a clear compliance with the project documentation. Before installation, be sure to check all dimensions for possible deviations and rejections.

Attention! For all products and parts for such a ladder, certificates of conformity are mandatory, in which all their technical parameters are indicated, and they themselves must be marked.

According to GOST 8717.0-84, the following maximum permissible deviations from the linear dimensions of the steps in any direction are established:

- no more than 5 mm along the length of the product;

- no more than 3 mm in width;

- no more than 2 mm in height.

Also, the instruction does not allow the installation of stair steps that have gained less than 70% strength. Separate requirements relate to the appearance and uniformity of the surface color.

Features of marking

In private housing construction, building a staircase from reinforced concrete steps and based on the size of the room where the formation of a staircase or the placement of marches is planned, products are selected according to the marking, which is easy to decipher.

These are alphanumeric designations, where the first group of symbols indicates the type and size, the second group is the concrete grade. For example, ladder steps LS 14 V15.

There may also be additional information about the embedded elements, the method of finishing and the type of product. For example, the letter "G" stands for a smooth surface, and the letter "W" for a rough surface.

The length is indicated by the number immediately after the letters LS:

- 11 is equal to 1100 mm;

- 12 - 1200 mm;

- 15 - 1500 mm, etc.

The depth of the steps for standard products is 330 mm, and the height is 145 mm. If the size is non-standard, these values are additionally indicated on the marking. For different types of stairs and their installation, see the video in this article.

Conclusion

Regardless of how the work is carried out - independently with the assistance of assistants or a specialized team - you must remember about safety and conduct work in compliance with all standards.

Instructions for the production of work related to the construction of stairs, including from reinforced concrete steps, are contained in SNiP 3.03.01-87 clause 3.3.