What can be used for internal and external stair treads? Wood, steel, glass, concrete ... And if you use clinker tiles as a coating? Let's try to weigh the pros and cons of this solution.

What it is

What is clinker? This is an ordinary clay that has been fired at a high temperature. It is the high-temperature firing that distinguishes clinker tiles from ordinary tiles: at 1300-1400 degrees, the mineral particles that make up the clay are reliably baked together.

The resulting material is superior in strength to many types of natural stone and at the same time is deprived of their main vulnerability - the ability to accumulate water in cracks and faults. Stone erosion is primarily associated with the destruction of the surface layer due to the crystallization of water: ice, after all, has a greater volume.

Clinker has water absorption no more than 3%; as a result, the material boasts excellent frost resistance - at least 100 cycles, which in practice corresponds to the period of operation without destruction in 250 - 300 years old.

It is worth clarifying: clinker with frost resistance F 100 is considered budgetary. For clinker steps of German and Italian production, frost resistance of 300 cycles and higher is considered the norm.

Advantages and disadvantages

Let's try to evaluate the consumer qualities of clinker as a finishing material for steps.

pros

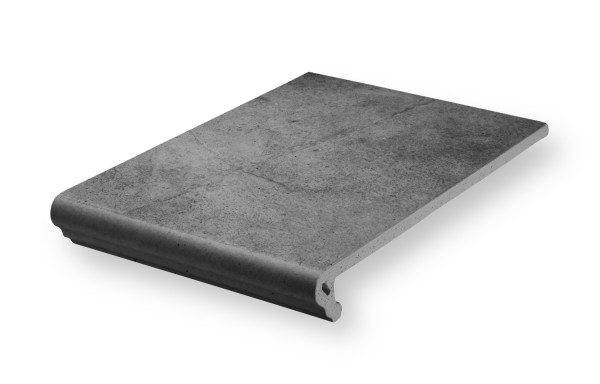

- Great appearance. Thanks to the addition of mineral dyes, modern clinker steps are in no way reminiscent of the dull tiles in the bathrooms of our grandmothers: the exterior of the porch covered with clinker cannot be called otherwise than exquisite.

- The material is extremely durable. Believe me: with the usual mode of operation for a residential building, some signs of wear on your porch will appear unless your great-grandchildren.

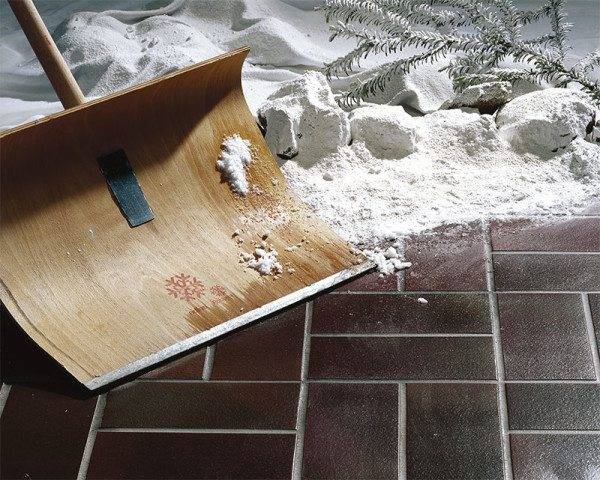

- Any changes in temperature and humidity are not terrible for the clinker coating. There is no need to be afraid of cracks or erosion.

- Clinker tiles for stairs have a characteristic rough surface, on which it is impossible to slip. If the porch is steep, and there are elderly people among the tenants of the house, there is no problem: it is easy to find steps on sale with a notch, with which even ice is not terrible.

- Easy surface care - another undoubted advantage of the material. The extremely dense surface prevents dirt and dust from entering.

You can wash the clinker using any cleaning agent: to leave traces on it with an abrasive powder, you will have to spend more than one day. Of all household chemicals, only concentrated acids can leave traces on it, and then with prolonged exposure.

Minuses

Does the solution have any shadow sides? Perhaps only a fairly high price. One step measuring 325x325 millimeters can cost the buyer 300-600 rubles. For comparison - the same is the price of a square meter of high-quality floor tiles, which fundamentally differ only in firing at a lower temperature.

As an excuse for manufacturers: the consumption of thermal energy with an increase in the firing temperature increases non-linearly. During firing at 1300 degrees of fuel, it takes four times more to maintain the operation of the furnace than at 80 ° C. Taking into account the duration of the operation in tens of hours, the difference in costs becomes more than tangible.

Summary

Clinker steps are a practically eternal solution that does not have any drawbacks, except for a rather high cost. If she does not bother you, you should definitely not look for other options.

Application

How to prepare the base and lay the clinker steps with your own hands? The instruction is no different from laying any other frost-resistant tile.

Preparation of the base

- The surface is carefully leveled. Peeling plaster is removed with a pick and steel trowel. All protrusions are cut off with a chisel; it is better to fill significant depressions with cement mortar (if necessary, with a closure of broken stone or brick). Of course, nothing prevents you from filling them with tile glue, but in this case, the costs will increase significantly: high-quality glue is not cheap.

An important point: if you are going to decorate an old concrete porch-staircase with clinker with your own hands, which has managed to become covered with a network of deep cracks for decades, do not be too lazy to put a reinforced screed under the tile. In most cases, opening the porch, you will find inside not reinforced concrete, but brick or masonry on an order of sagging soil.

- Remains of dirt, dust, grease and paints are removed from the surface of the reinforced concrete porch-stairs. Bare concrete does not need additional processing, but any absorbent and dusty coatings (yes, it is not always possible to remove dust completely) must be primed. The best soil for our purposes is the one that gives a rough surface with excellent adhesion "concrete-contact".

- The tile adhesive is mixed in strict accordance with the instructions. It is not necessary to determine its consistency by eye or, contrary to the guidance, add water to the mixture, and not vice versa. The mixing utensils must be clean: lumps will interfere with the application of the glue in a thin and even layer.

Styling

When it comes to outdoor stairs, the glue is only frost-resistant, even if you live in Crimea.

- The glue is applied with a trowel and leveled with a 6x6 - 8x8 mm comb-type trowel. The steps are neatly tapped on top with a trowel handle and checked with a level. 5 mm expansion joints remain between the tiles; for control, crosses of the appropriate size are used.

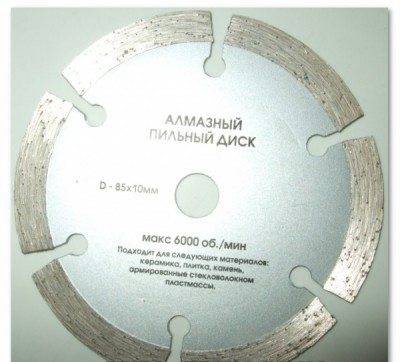

- A tile cutter or a grinder with a diamond disc is used for cutting. Cutting clinker tiles with an ordinary cutting disc in stone is a hopeless undertaking.

Output

As you can see, the advantages of clinker as stair steps are undeniable, and its installation does not present any particular difficulties. In the video presented in this article, you will find additional information on this topic (also learn about the advantages of dielectric ladders).

Good luck in construction!