An alternative to traditional constructions are ladders on the bolts. The word "bolts" itself comes from the German word "bolz", which means "bolt". This type of stairs learned this name because its basis is the fastening.

Next, we will consider the features of such a design and the technology of its independent manufacture.

General information

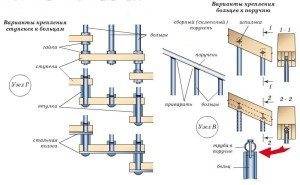

As a rule, on one side, the steps will be attached to the wall, and on the other side they are held by a handrail, which is a supporting part. If the wall is not strong enough, then the treads are installed on a stringer or bowstring. Sometimes the treads are attached to the bolts on both sides.

As a result, visually one gets the impression that boltsevo staircases are floating in the air. This effect is enhanced by the absence of risers.

Any type of structure can be built on bolts:

- Marching straight

- Marching U-shaped staircase,

- L-shaped;

- Screw.

Such stairs are especially well combined with high-tech interior style. Metal structural units and fasteners, which remain visible, become an element of its decor.

The design of the stairs on the bolts has one more advantage - it is maintainability. Any of the feet can be replaced without affecting the rest of the elements. In addition, such structures do not creak, since they do not have wooden joints.

Accessories and materials for stairs

The main accessories products are the following items:

- Bolza. They can be of different shapes.

- Balusters. They can be wooden or stainless steel.

- Steps.

- Handrails.

Material for steps

If the treads are made of wood, then they use durable types of wood, such as beech, oak or ash. The use of soft rocks can cause them to deform over time. The minimum board thickness should be 6 cm.

If the treads are made of glass, then tempered glass must be used. The disadvantages of this material include susceptibility to end impacts, which can lead to chips. Acrylic glass is more durable, but scratches appear over time.

Sometimes the steps are made of stone. In this case, quartzite or granite is used. For outdoor structures, stainless steel can be used.

Bolza

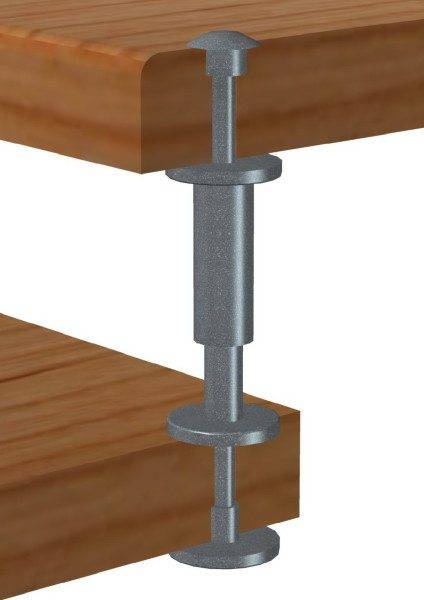

Boltz is a metal rod that is attached to the handrail at one end and to the step at the other.

When self-manufacturing the structure, it is better to buy ready-made bolts for the stairs. It should be borne in mind that they are in sight, therefore, they can also perform decorative functions.

Advice! In appearance, the bolt should be chosen taking into account the general appearance of the future design and the characteristics of the interior. Depending on the design, the price for their various types can vary greatly.

Create stairs

Payment

Before you start creating a staircase with your own hands, you need to make a calculation, as is the case with any other structure. This will make it as comfortable and safe as possible.

An example for the calculation is a boltsevo staircase with two flights. The spans will be at right angles to each other.

That is, it will be a rotary structure with an intermediate platform. The height of the product should be 3m, and the width of the march should be 1m.

The most comfortable and safe height of the steps is 15 cm, and should be based on this when calculating the required number of steps. By dividing the height of the structure by the height of one step, we get 20 steps.

As a result, for the first march, 9 of them will be needed, since the turning platform between the marches will serve as the tenth step.

From the site, at an angle of 90 degrees, another march with nine steps will be located. The tenth one coincides with the floor of the second floor.

The optimal tread depth is in the range of 25-40 cm. If the tread depth is taken as 25 cm, then the length of the marches will be 2.25 m. The intermediate platform will be square, with sides 1m wide.

With such parameters of the product, the opening will be 3.1 * 1.3m

Advice! The distance from the wall to the handrail must be at least 10 cm. Otherwise, you could injure your hand.

When calculating the depth of the tread, it is necessary to take into account whether they are mounted with an overlap. The front edge of the upper tread rests on the rear edge of the lower tread. If the overlap is 5 cm, then the width of the tread should be, not 25, but 30 cm.

Making a ladder with one bowstring

Suppose that a do-it-yourself ladder made on bolts will have a bowstring on one side, since this is the most common and simple design.

The instructions for its manufacture are as follows:

- First of all, you need to determine the size of the bowstring. In cases where winders are installed, the dimensions may differ in some of its parts (find out here what a ladder with winders is).

- Then you need to fix the string on the wall and attach the tread to it.

- Next, the balusters are installed. It should be borne in mind that they are a supporting element, so they should be fixed very firmly. The mounting of wooden posts is usually done with metal brackets.

- Next, a handrail is installed on the balusters. Supports are usually attached to it with bolts, studs, or threads. At the same time, in all cases, a prefabricated U-shaped handrail is used.

Note! Do-it-yourself ladders made on bolts can be shifted to the side, as a result of which the steps will fall out of the bowstring. Therefore, all parts must be especially secured.

If the handrail is mounted on studs, then holes must be made in it, which will coincide with the diameter of the holes at the ends of the supports. A hairpin is threaded through these holes.

If the fastening is carried out on bolts, then a metal handrail is used to which the bolts are attached. A wooden handrail is installed on top of it. Also, when using a metal handrail, the supports can be simply welded to it.

Output

Bolt-on structures have many advantages over conventional staircases, but their most important advantage is their unusual appearance. Wooden staircases on the bolts look especially interesting.

They seem light and airy, which is what draws attention to myself. Such a staircase can decorate the interior of your home (see also the article Stainless steel stair railings: nuances, types, production).