In a private home building, you always need to make non-standard decisions and this is one of the aspects of the individuality and attractiveness of such a building. One of these problems may be the question of how to weld a staircase from a metal corner or other profile for the interior, while retaining all the design possibilities.

Also, a video in this article will tell you about stairs and welding work with them, which will be here as an addition to the material.

Materials and work

To determine the cost of welding a staircase, or at least draw up an action plan, you need to determine which structure you want to install in your home (or at home). Depending on the design of the arrangement, you will need certain materials, and even their number will differ significantly, because the entire staircase is not only steps.

Types of ladder structures

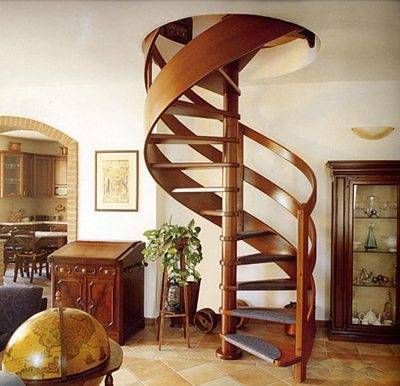

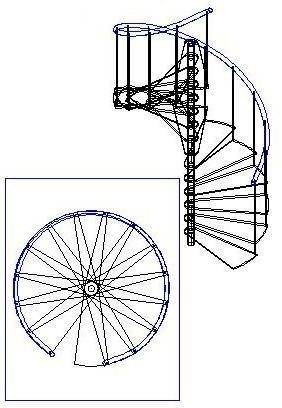

- If the steps of the stairs are located around a vertical rack or, as it is called, a casing (an example is located in the photo above), then such arrangements are usually called spiral or screw... Such marches do not need additional fasteners, but there is a difference between them, so if the spiral structures are located only on vertical supports, then the screw ones can also be held on kosoura or bolts.

- The bolt-on structure (bolted or bolted) has an invisible step fastening system. It turns out that the steps themselves are held by rubber gaskets inserted into the wall and the steps are held on to them and on the balusters, which, in turn, are attached to the railing... Due to the ease of projects of this kind, they are quite in demand in modern design, besides, the total price of all materials is not too high.

- A stringer is a supporting beam for stair flights, on which a comb is mounted on top for mounting steps (most often two such beams are installed - on each side of the steps). Such beams can be straight, rounded or jagged, which ultimately denotes the shape of the entire staircase, that is, it can turn out to be straight, broken (jagged) or curved.

If two kosour are involved, then the design is usually quite massive and suitable for large rooms, but the use of kosour in the singular, as can be seen in the top photo, allows you to minimize the dimensions.

- Folding or retractable structures are more suitable for entrances to the attic from the side of the apartment or for the street... As a rule, such an arrangement is very simple in execution and is made either from wood or from metal, but sometimes materials are combined.

Advice. When you choose the type of stairs for your home, you will have to pay attention not only to its design, but also to the possibility of placing it in one or another part of the room.

After all, even a spiral structure, which takes up a minimum of area, may simply not fit in size, but in the same place you can place steps on kosoura - thanks to the slope, the marches bypass obstacles.

Metal staircase on kosoura

Let's figure out how to weld a metal staircase with our own hands on kosoura, because now there are all the possibilities for this. We are talking about tools for processing profiles - we offer side grinders (grinders), electric drills and, of course, electric or gas welding - having such an arsenal at our disposal,you don't even need a hacksaw for metal.

First of all, we need to make a frame or kosour and the best profile for this is an I-beam or channel, but other configurations can be used. (see also Stairway rungs: protection, decor and comfort)

- Sawtooth shape of the bowstring;

- Bowstring made of sheet metal;

- Serrated section;

- Channel bowstring;

- Box-shaped kosour;

- I-beam kosour;

- Kosour without brackets;

- Kosour with brackets.

Thanks to the top schematic drawing, you can decide how to weld the frame for the stairs, that is, choose the right bearing elements for the steps. Such a design can serve both for the street and basement, and inside the apartment, if it is given the proper design.

For treads, any safety instructions will recommend you a corrugated surface, so corrugated sheet steel is convenient for indoor use, but undesirable for outdoor use.

The fact is that the snow that remains on the metal surface will crumble and, thus, the treads will turn out to be slippery, that is, traumatic. Therefore, for arranging street steps, it is recommended to use corrugated reinforcement, welding it to the kosour comb with a step of 5-7 mm - snow will fall into these gaps and the plane will remain clean (not slippery).

The safety of operation is influenced not only by the mechanical qualities of the profile, but by the rationality of the design, since you can weld a ladder with your own hands in different ways. This, first of all, applies to the manufacture and installation of stringers, because the profiles have to be cut in certain places, weakening their strength. (see also Wrought iron stair railings: types and styles)

Therefore, the shelves of the channel or I-beam must remain intact even if this interferes with the installation of the treads (the tread may protrude beyond the shelf, then not the shelf should be cut, but the tread).

Also, metal processing is of great importance for safe operation, because after such a process, burrs and sharp edges remain, which are often the cause of injury. Particular attention should be paid here to handrails and balusters, that is, those places where the most frequent contact with the human body takes place.

When this is neglected, not only arms, but also legs can be injured, as well as cases of falling (loss of orientation from painful shock) are possible.

- Kosour from the channel;

- Sheet metal treads;

- Brackets for attaching treads and risers (optional);

- Bracket fixation points (welding or bolts (bolts));

- Tread fixation points (welding or bolts (bolts)).

Pay attention to how the comb is made on the stringer (schematic image above) - metal triangles are welded onto the channel, which are best made from a hollow rectangular profile, for example, 2040 mm - such a bracket will not bend. In addition, from the same profile, you can weld a base for a tread, although reinforcement is also suitable for this.

Advice. Do not forget that a hollow profile is always better than reinforcement in terms of mechanical bending strength, although it is much more expensive financially.

If you still make triangular consoles on a comb from reinforcement or a metal strip, then you can compensate for their strength, as well as the strength of the tread, with a riser. That is, do not make it solid, from the top tread to the bottom, but simply weld a strip in a vertical position under the tread. You will achieve the same effect if you bend the near edge of each tread vertically, forming something like the letter G.

Many are interested in how much it costs to weld a ladder, but the prices for work depend on the skill of the welder (usually certified welders, especially those with a personal stamp, take hourly and expensive work for the job). But the calculations should also include the cost of the material, which usually turns out to be equal to the cost of the work.

Advice. Railings (handrails and balusters) for a metal staircase of this type should not be an addition, but an integral part of the structure.

This suggests that they will be rigid, having a connection with the racks on which the stringers are mounted.

Spiral staircase

Now let's take a quick look at how to weld a spiral staircase, and in short, because such work requires high professionalism, so it will be appropriate to pay attention only to general provisions. The most demanded diameter of such a structure is from 1.2 to 2.0 m, therefore the occupied area in the apartment, respectively, will be equal from 1.7 m2 up to 4.2m2.

In this case, if you need to weld a staircase to the second floor, then the basis for it will be a vertical post on which the entire structure is located. The support pillar at the bottom is attached to the floor, and at the top, fixation can occur in two ways - either to the ceiling, which is not always possible, or to the wall, through the top step.

The steps (treads) are fixed with one side to the pipe, as if strung on it, with a gradual turn. The far edge of the treads is framed by a railing, that is, a continuous spiral strip is welded to the bottom, on which balusters are mounted, and handrails are already attached to them.

Everything together should be a one-piece structure without any backlash on the connections, otherwise the arrangement will simply fall apart.

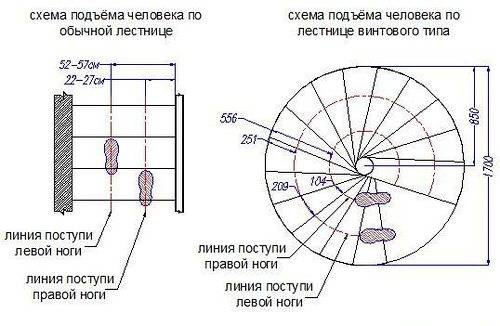

When using narrow spiral staircases, it should be borne in mind that the width of the treads, taking into account the railing, is more than halved (with a diameter of 1.2 m, the width of the tread will be 0.5-0.55 m). Therefore, it is advisable to use structures with a small diameter only for utility rooms, that is, for those where they do not climb so often.

You should always remember about the main feature of the screw design - the steps on one side overlap each other (most often this happens on the left side, where the rotation is carried out counterclockwise), so we can put less than 59% of the left foot on the floor.

For a comfortable feeling, at least 70% is required, which means that the diameter of the stairs needs to be increased. A person will feel most comfortable if the span width is at least 75-80 cm, then the diameter of the screw should be more than 160 cm.

Conclusion

As you understand, it is possible to weld the staircase frame only after careful calculations of the entire structure, but in this article there is not a single one possible. (see also Interior of a hallway with a staircase - ideas and rules) But the point is that such designs are purely individual for each case and ready-made calculations simply do not exist.