A spiral staircase is a structure that consists exclusively of winding steps. Most often they are made of wood or metal.

Next, we will consider how to independently calculate a spiral staircase and give a brief technology for its manufacture.

General information

Types of spiral staircases

Before proceeding with any calculations, it is necessary to decide on the type of structure.

They are of several types and primarily differ in form:

- Polygonal.

- Round.

The polygonal shape can be used if the structure will be installed next to a wall. This solution will save space even more. If the staircase will be placed in the center of the room, then it is better to use a round shape.

Also, spiral staircases are distinguished by type of construction:

- With the support of steps on the walls, which are located along the perimeter (the staircase is formed in the well).

- Stand-supported.

- With the support of steps on the fence or bent bowstrings.

When using a support leg, the device also differs in:

- Pinching the tread in the rack.

- Leaning the tread on the counter.

It is very difficult to make a bent ladder bowstring with your own hands, therefore, with the independent manufacture of the structure, this option disappears. You can build a well, if this does not contradict the general concept of the interior. However, the best option is to support the console on a rack.

Design features

Spiral staircases are most often made without risers, as they make the structure inconvenient to use. The fact is that in the midline the width of the winder stair step is narrower than the length of the foot, so the leg becomes incomplete. As a result, there is a risk of slipping, which can lead to injuries.

The absence of risers allows the entire foot to be on the tread. Thus, the movement on such a ladder is more convenient and safe..

Existing standards

When designing a spiral staircase, the following dimensions must be taken into account:

- In the area of the traffic line, the tread width must be at least 20 cm.

- The width of the tread at a distance of 15 cm from the rack must be at least 10 cm.

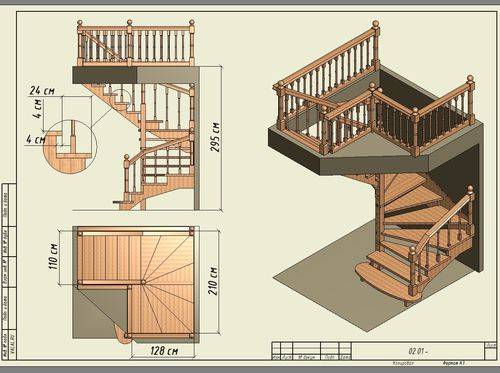

- If the spiral staircase is the main one, then the length of the march should be at least 80 cm, and the diameter of the ceiling should be at least 200 cm.

- If the ladder is used as an additional one, then the diameter of the opening is allowed - 14 cm.The length of the tread should be at least 55-60 cm.

The size of the structure also depends on the size of the opening in the floor. Moreover, in diameter, it should be less than the opening. The difference is usually two thicknesses of its finishing material.

It should also be borne in mind that a spiral staircase can be convenient not only for moving along it, but also for carrying loads. But, for this, its diameter must be at least 220 cm.

There are typical sizes of spiral staircases, according to which:

- The width of the flight of stairs should be between 53 - 143 cm.

- Along the outer edge of the railing, the diameter of the stairs can be in the range from 130 to 330 cm

- The diameter of the hole in the ceiling must be between 140 and 340 cm.

- The diameter of the passage along the inner edge of the railing can be in the range of 120 -320 cm.

- The distance between the turns must be at least human height.

Advice!

For lifting equipment to the attic or attic, a compact staircase can be installed.

In particular, it can be installed even in an opening of 120 × 60 cm.

Sizing calculation

A steel pipe 6-8 cm in diameter is suitable as a support for the structure, while the wall thickness should be at least 5 mm. The frame of the consoles is most often boiled out from a steel corner. The consoles themselves can be made of solid wood.

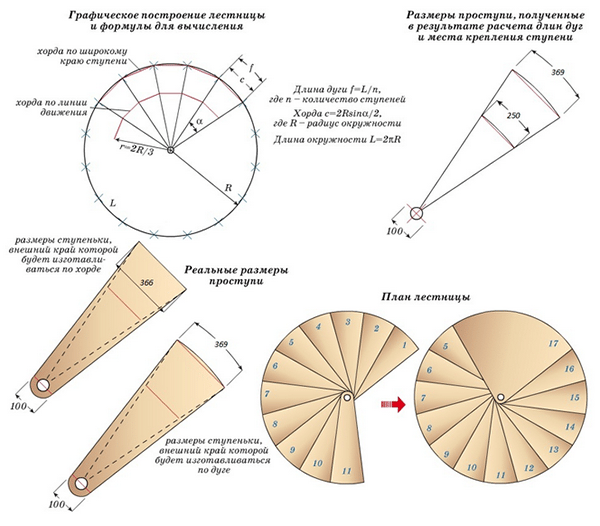

Circumference

In further calculations, the radius of the opening circle will be denoted as - "R". It is also called the outer radius of the console. It is also necessary to take into account the inner radius of the opening, which will be designated as - "R1", it includes the radius of the support pipe + the thickness of its wall.

One of the most important parameters of a spiral staircase is the number of turns that it makes a march around the reference axis. The revolution is denoted as - "γ" and is expressed in degrees (one revolution - 360◦). Sometimes it is expressed by the dimensionless quantity - "n". For drawing constructions, the angular value is more convenient, and for calculations it is dimensionless.

Advice!

If the structure contains one revolution or even more, then it should be taken into account that the distance between the steps lying one above the other must be at least 1.9 m.

Otherwise, the stairs will have to be bent over.

According to the formula, the circumference marked as "L" is:

L = 2πR * n or L = 2πR * (γ / 360).

But, this value does not suit us, since no one will walk along the very edge. Therefore, the circumference should be calculated along the line of movement. As practice shows, the radius of the path of movement, which is designated as "r", is two-thirds of the radius of the staircase, i.e. - 2R / 3. Therefore:

l = 2π * 2R / 3 * n = 4πR / 3 * n

Dimensions of steps

The main feature of spiral staircases is the specific form of the tread. A step of this design is a petal, which is rounded on one side.

The console is characterized by the following parameters:

- The length of the step, which is designated as "h". To calculate this parameter, it is necessary to subtract the outer radius of the support from the radius of the staircase.

- The maximum width of the cantilever, denoted as "W1", is a chord along the wide edge of the tread.

- The width of the workpiece, denoted as "W2" - is the size of the tangent to the circle of the step, which is limited by the extended radii built along the edges of the tread;

- The angle of the step, denoted as "α" - is calculated as the angle between the radii of the opening, which are drawn through the edges of the steps.

Advice!

If the length of the tread is less than a meter, then it can be done without a hardwood frame.

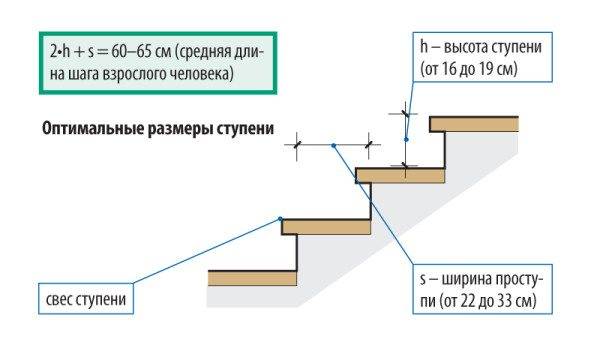

As in the case of a straight flight, the number of consoles is calculated by dividing the height of the opening by the height of the step. In this case, the rise should be within 15-20 cm. As practice shows, such a height when walking is the safest and most comfortable.

The step angle "α" can be calculated using the following formula: α = γ / number of steps.

Knowing the tread angle, as well as its width, you can calculate the maximum tread width by the formula: W1 = R * sinα

We need to find out the width of the tread in the center, that is, on the line of movement, which is designated - "W", for this we need to perform the following calculation: w = r * sinα = (2R * sinα) / 3

The width of the tread on the line of movement should be 20-30 cm. If the value obtained during the calculations does not fit into this range, then the number of consoles should be varied. However, in this case, the rise of the step will change.

If, when changing the number of steps, the rise is outside the permissible range, then it is possible to change not the number of consoles, but the turn of the ladder. In this case, instead of the upper tread, a platform of the required size is installed.

It is more convenient to perform a design drawing as a scan based on a vertical and horizontal projection. It is better to make two such sweeps, not only along the plane of the outer curb line, but also along the path line.

Now that all the calculations have been completed, you can start making a spiral staircase.

Advice!

If the treads are overlapped with respect to each other by a few centimeters, this will provide comfort of movement.

In addition, this will further strengthen the entire structure by installing a bracket between the edges of the extended part of adjacent consoles.

An example of making a staircase

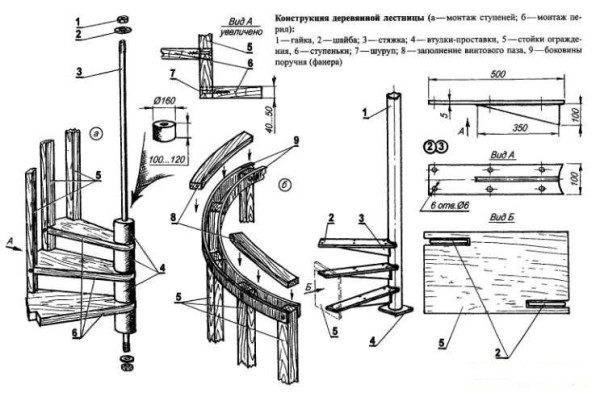

Consider, as an example, the manufacture of a B-pillar structure. As a stand, we take a thick-walled metal pipe 50 mm in diameter.

A quick guide looks like this:

- It is necessary to weld a union with a thread and a nut to the upper end of the rack. The base of the post is concreted or fixed with anchor bolts.

- With the help of a special drill, most often this is a perk, a hole is drilled from the narrow side of the steps. It must match the outer diameter of the pipe so that the step fits snugly on it.

- The distance between the consoles is adjusted by means of bushings that are put on the pipe between them. The inner diameter of the sleeve must match the diameter of the tread hole.

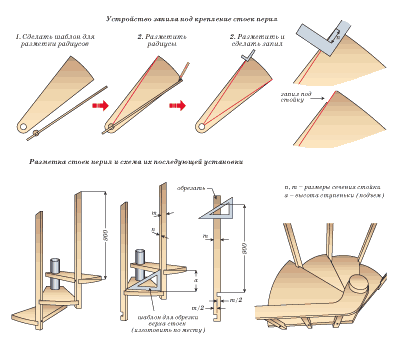

- On the wide side of the steps, holes are drilled for the support bracket and handrail posts.

Advice!

If the structure is installed on wooden floors, the B-pillar can be secured with screws.

For this, a flange with holes is welded to the pipe.

The assembly of the structure is carried out in the following sequence:

- The central post is fixed and a sleeve is put on it, which corresponds to the height of the first step, after which the first tread is put on.

- Then the next sleeve is put on, which adjusts the height of the second stage and the next stage is installed, and so on until the last stage.

- A bracket is installed between the front of the wide end of the upper tread and the rear of the wide end of the lower tread to support the upper tread.

- After installing all the steps, a bushing is put on the end of the rack pipe using a threaded connection. After that, it is necessary to tighten the top nut with a decorative cap.

- At the end of the work, the upper console is attached to the interfloor beam.

Advice!

A wide metal washer should be installed between the bushing and the wooden tread.

This will add strength to the structure.

Output

If all the calculations were performed correctly, in accordance with the above formulas, and the installation was carried out according to the instructions, then the result is a fairly strong, comfortable and safe staircase in operation. At the same time, the price for it will turn out to be several orders of magnitude lower than for a factory, finished product.

You can get more information from the video in this article.