Today, in the manufacture of stairs, it is not at all necessary to completely independently make the structure, or vice versa, to buy a finished product. The fact is that on the market there are a variety of wooden and metal components for stairs, from which you can assemble a product to your taste. This allows you to combine ready-made and home-made elements and, thus, bring any idea to life.

Next, we will consider what elements the ladder structures of various types consist of, and what accessories for stairs it is better to buy, and which ones you can do yourself.

Common elements

Some ladder accessories are used in all types of structures. These include steps and railings, which are probably all that different types of staircase structures have in common. Let's take a closer look at each of these details below.

Steps

Undoubtedly, the steps are one of the main elements of the product, since they bear the power load from the person walking along them. Accordingly, reliability is one of the main quality criteria for this element. In addition, for a step to be safe, its dimensions must comply with certain building codes.

Treads are made from various materials, however, the most popular, especially in private construction, is hardwood.

Usually this:

- Oak stairs;

- Ash;

- Alder;

- Larch

Steps are a simple element that is much more profitable to make on your own than to buy a ready-made one. When self-manufacturing, it is important to pay attention to the quality of the material..

The main requirements for it are as follows:

- Permissible humidity level;

- No knots.

Advice!

If the steps are made with risers, then they must be made from wood of the same species, since different species react differently to atmospheric conditions.

Railings

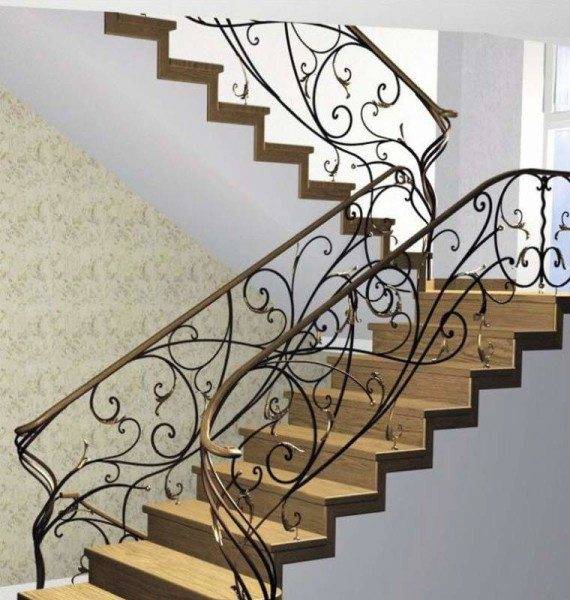

First of all, you should indicate what is meant by this word. Many people think that a handrail is a handrail, an element that completes the overall ensemble of the product. However, in reality this is not the case. Railings are railings that consist of balusters, crossbars and a handrail.

Fences also come in a wide variety of materials. Moreover, in addition to their main function, they, most often, are also an element of decoration. Therefore, the material should be selected in accordance with the general appearance of the product and the style of the interior, since the external staircase depends on the fence.

Advice!

Combined railings look especially beautiful, for example, stainless steel balusters, and a handrail made of wood.

Staircase accessories are among those elements that are best purchased ready-made, unless, of course, you are proficient in the art of artistic woodcarving.

Advice!

If you decide to use forged products, then it should be borne in mind that forging loves "their own kind". Therefore, among the elements of the interior, there should be other forged products.

Railings made of wood are especially popular. Moreover, unlike feet, any type of wood, both hard and soft varieties, can be used for their manufacture.

In particular, you can find fences from:

- Beech;

- Oak;

- Ash;

- Hornbeam;

- Birch trees;

- Alder;

- Pines;

- Larch;

- They ate.

Therefore, the starting point when choosing a material can be the price.

Marching

Device

Marching stairs are perhaps the most common type of construction. They can be made of wood or metal.At the same time, accessories for metal stairs are the same as for wooden products.

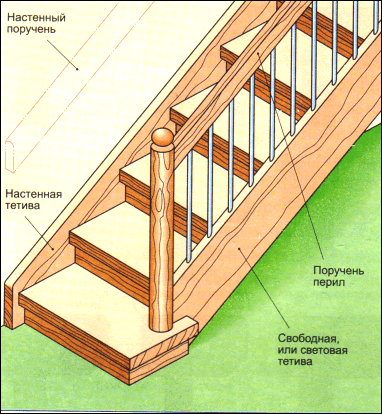

They are based on two (sometimes more) inclined bearing beams, with the exception of structures on the bolts. Depending on the type of fastening of the steps, the bearing beams are distinguished into bowstrings and stringers.

The marching staircase designs made of a metal frame and sheathed with wood are very popular. If you have experience with a welding machine, then you can make metal accessories for the stairs with your own hands. At the same time, the aesthetic requirements for the frame are not great, since it will still be closed by a tree.

Bowstring

Bowstring stairs can be made of wood or metal. The beam thickness should be at least 50 mm, and the overall width should be about 300 mm. A distinctive feature of the bowstring from the kosour is the presence of cutouts into which the steps are embedded.

The depth of the tread cut can vary from 20 to 30 mm.

The dimensions between the cuts and their widths depend on such characteristics as:

- tread width;

- tilt angle;

- lifting step height.

If you look at the product from above, then both beams are visible. Most often, with such a construction device, risers are used. Fences can be mounted both on the bowstring and on the steps.

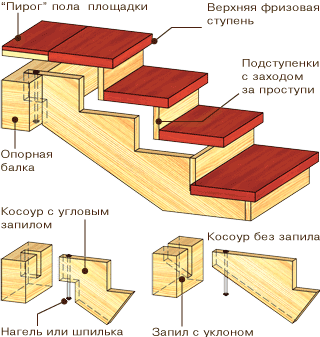

Kosour

The stringer, as well as the bowstring, determines the length of the march, while the same width and thickness requirements are imposed on it as to the bowstring, i.e. 50 * 300 mm. On the upper side of such a beam, a comb is made in the form of triangular cutouts, which form the step and the main characteristics of the product.

The tread is placed on such cutouts, as a result of which the beams are hidden under them. Therefore, unlike the bowstring, they are not visible when moving up the stairs. There are elastic structures made on the basis of one kosour, which is called the central one.

The choice of the type of support beam depends on your taste. In terms of manufacturing complexity, they are about the same, as well as in terms of reliability. The supporting base is not difficult to do on your own, the most important thing is to correctly mark the blanks.

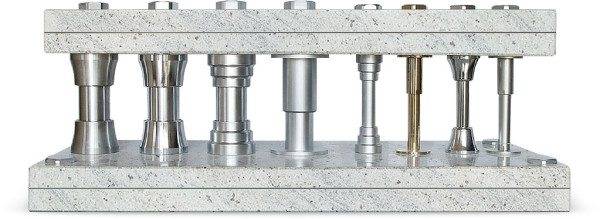

Bolza

Unlike the previous two types of structures, the main staircase on the bolts does not have support beams, or the beam is used on one side. In this case, the entire load falls on the handrail, from which the bolts go, and they, in turn, hold the steps.

Due to the absence of massive beams, such structures look light and visually give the impression that they are just floating in the air. Another feature is that the mounts are visible and have a decorative function.

Therefore, it is better to buy factory-made components for stairs of this type, since they come in different shapes and look very beautiful. It is simply impossible to make such mounts at home without special equipment.

Screw

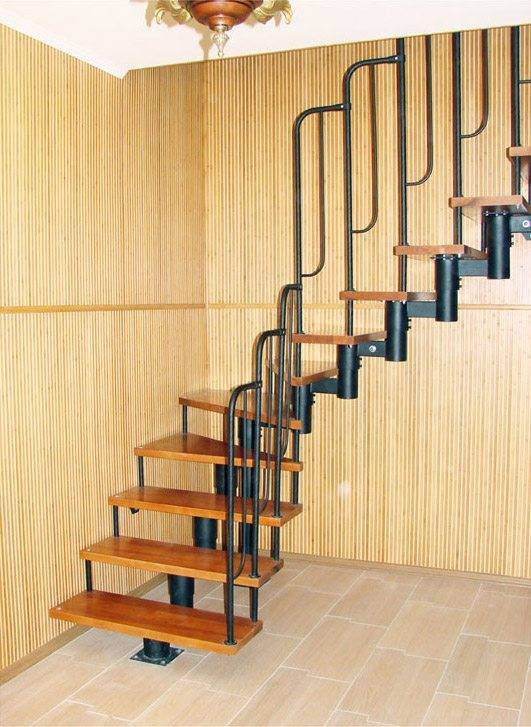

Unlike sustainer, screw structures do not have support beams.

Spiral staircase accessories include the following items:

- The central post, which serves as the main load-bearing element, to which the run-in steps are attached. As a rule, the post is a pipe with a diameter of 50 mm and a wall thickness of 5 mm. The lower end of the pipe is concreted or fixed to the base with anchor bolts.

- Winder steps. They have holes that are threaded onto the pipe, while the height of the steps is adjusted by the bushings between the steps. There are also other types of fastening steps to the support, for example, with the help of consoles, but, in any case, they are located around it with a screw.

- Supports. On the reverse side, they connect the treads to each other. Balusters also perform this function. In this case, the upper step always rests on the edge of the lower one.

- Sometimes in such a design there are bolts and even a curved bowstring, from the side of the opposite support.

- Railing.

Advice!

When calculating steps for a spiral staircase, you can use the rules for calculating winder steps.

I must say that this design is rather difficult to manufacture, but at the same time it does not take up a lot of free space and provides comfort when ascending and descending. Therefore, it is better to purchase ready-made components for a spiral staircase.

In this case, all that remains is to assemble the stairs at the facility, which is not particularly difficult. This also applies to railings, as they have a complex, curved shape.

Modular

Modular products deserve special attention. In fact, they do not require the independent manufacture of any elements at all, since they are assembled from separate sections like a large designer. True, accessories for modular stairs, most often, can be selected at your discretion.

Such products look quite elegant and easily fit into any interior. At the same time, in terms of strength, they are not inferior to solid marching stairs. Other advantages include compactness. They can be installed even in small apartments.

Accessories for a modular staircase are calculated according to the height of the room and the angle of inclination. The most important thing in the installation of the structure is to correctly install the ridge, which consists entirely of individual modules. The reliability and durability of the product depends on its installation.

The kit always contains instructions, so it is not at all difficult to complete the installation yourself. I must say that both marching and spiral staircases are modular.

We suggest watching the video in this article, which clearly demonstrates the installation process of such a design.

Output

After you figure out which structures are made of which components, it will be much easier to decide on the type of future ladder and then assemble it yourself.

For example, it makes no sense to buy steps, since they are easy to make yourself, while it is better to buy ready-made components for stairs on the bobbins. Such a rational approach will not only save money, but also make the stairs beautiful and reliable.