Stairs are an indispensable architectural attribute for a multi-tiered house or cottage. They are built from various materials, but the most versatile means for this is wood, which is combined with almost any interior and creates a feeling of warmth, coziness and comfort in the house.

In addition, it is easy to work with such material, therefore, with the help of it, wooden stairs to the second floor - created with their own hands - are quite feasible task.

Advice!

It is not necessary for these designs to choose expensive exotic wood species.

For example, if you choose a suitable design, then stairs made of beech, pine or ash look quite presentable, despite the fact that their final price turns out to be quite democratic.

Of course, building a staircase requires some knowledge and skill in carpentry. If everything is in order with this, then, before proceeding with the actions, you first need to prepare by studying the step-by-step process of making a staircase to the second floor from wood and the rules that should be followed in the construction of lifting belts.

Tool and material for making wooden stairs

In addition to the wood itself, for the construction of this structure, you will need to purchase additional material and the following tools:

- drill;

- screwdriver;

- roulette;

- pencil;

- hacksaw for wood;

- level;

- building corner;

- hammer;

- Sander;

- brush;

- fastening material (screws, nails, dowels, anchors);

- drying oil;

- varnish.

Preparatory work before the construction of a wooden staircase

Any structure requires a drawing, in which the dimensions of each component are already precisely determined. This also applies to the lifting belt.

To create it, the type of structure is first selected, and measurements are made of the area where the wooden staircase to the second floor will be located. Further, with the help of existing modern computer programs, into which the available data are entered, a staircase project is drawn up.

You can also make calculations manually. There are special instructions and formulas by which the angle of inclination of the future lift, the size and number of steps, the length of the railing, balusters, and so on are calculated.

Before building the stairs, you will need to prepare the room, freeing it from unnecessary items that will interfere with work. Better if the room is completely empty.

Making a staircase from wood on kosoura for a summer residence, a cottage or a house

A wooden staircase is being erected to the second floor with their own hands in stages.

As a rule, the whole process of work includes the following steps:

- Measurement of the location of the lift.

- Ladder calculations.

- Drawing up drawings.

- Calculation and purchase of the necessary material.

- Manufacturing of blanks (in accordance with the dimensions available in the design drawing).

- Adjustment of the parts that make up the lift.

- Installation and fastening of all components of the staircase.

- Finishing finish.

After the drawing is prepared, the necessary material and tools are available, you can proceed directly to the manufacture of the lift. Straight wooden stairs for giving to the second floor are the most convenient and easy to build, therefore, using a specific example, we will consider how to make just such a structure, the basis for which will be stringers.

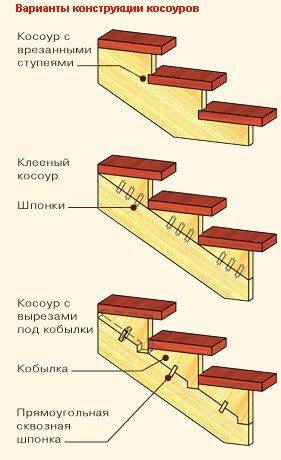

Kosour is a sawtooth wooden or metal beam.This device performs a reference function.

The steps themselves are mounted on the horizontal cut, and risers are attached to the vertical parts of the comb. You can make an open version of the stairs on the kosoura - in this case, the risers are simply not installed.

Note!

This type of lifting tape can be made both on one central stringer, where the steps are additionally fixed to the walls with the help of anchors, or on two.

The first option is convenient to use when there is a need to save material and the stairs are located along the wall.

In the second case, the design is more reliable and is also used when the lift is located in the middle of the room.

Since often wooden stairs for the second floor have a length of about 3 m, and the optimal number of steps is 15 pieces, in the further description of the process of erecting a structure on kosoura we will start from these data.

Making blanks for stairs

The manufacturing process for blanks includes the following steps:

- First you need to make 2 kosour... To do this, you will need 2 hardwood beams. The length of each of them must be the same as the height of the stairs, the thickness must be at least 20 mm, and the width must be 300 mm. A comb is cut out on it, depending on the height of the risers, the width of the steps and the angle of inclination of the stairs. It's easier to do this with a special corner, which will serve as a kind of template. The dimensions that were obtained during the calculations are set on it. Further, using a template, the places for the steps on the beams are marked with a pencil so that they have equal indicators.

- After that, the steps themselves are made directly in accordance with the design dimensions... Since the most optimal width of the flight of stairs is considered to be about 900 mm, then the size of the steps is made in accordance with these indicators. The thickness of the board from which the steps are made should not be less than 20 mm. After cutting them, all the edges of the workpieces are processed with a grinder.

- Then you need to prepare the balusters... They can also be made from timber. In this case, you will need 13 pieces of thin partitions and 2 more massive vertical posts, which will serve as the main posts.

But it should be borne in mind that now in the construction market the choice of such products is huge, so it is better to purchase them ready-made. This will save you time and effort. Their optimal height is calculated based on half the average human height (about 900 mm). - Railings are also best purchased in a finished product, since their manufacture is a laborious process.... When choosing, it should be borne in mind that their width depends on the size of the balusters. As a rule, the person's hand should be completely wrapped around the handrail.

They should not be too smooth. It is also unacceptable that they have notches on which you can get hurt.

Installation of stairs made of wood for the second floor

A step-by-step assembly process for this design:

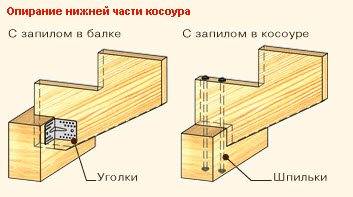

- First, it is necessary to install support profiles on the floor and in the ceiling opening using anchor bolts, where the stringers will be fixed in the future. You can also build a small platform on the floor, which will serve as the beginning of the stairs and support for the lower part of the stringers.

- Next, prepared beams are installed at the required distance from each other (depending on the width of the march). They are attached with special anchors to pre-installed lower and ceiling profiles. In this case, the correctness of installation must be checked by the building level. If the structure runs along the wall, then one stringer can be additionally fixed on the wall. The structure can be reinforced with several transverse boards fixed to the back of the structure.

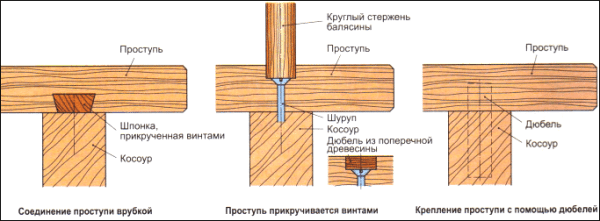

- After that, risers are first attached to the installed kosoura, and then the steps. There are many options with which you can fix these elements. It can be nails, screws, wood glue, and dowels. It is better when they are mounted with self-tapping screws, which should be placed in all corners of each part, while they must first be lubricated around the entire perimeter with glue, which will prevent the formation of a squeak during the operation of the lifting belt.

- Then the balusters are installed for the stairs. At the beginning and at the end of the structure, thicker vertical supports are attached, and decorative partitions (thinner) are installed in such a way that it is a baluster on one step. They are fixed on the steps with self-tapping screws, and the attachment points are hidden under decorative plugs.

- The handrails are installed on the underside of the handrails, which are also fixed on the balusters with self-tapping screws.

- After installing all the components, the entire structure must be sanded with a special machine or sandpaper.

At the last stage, when the staircase is ready and its strength has been checked, the structure is finished. Depending on the wishes of its owner, the structure can be painted or varnished.

The main thing is to remember that before that, any wooden stairs for the second floor must be treated with linseed oil (sometimes in several layers), which will prevent premature deterioration of this material from moisture. After the first application of paint or varnish, the layer must be allowed to dry well, otherwise the next layer of material will lie unevenly. The varnish is usually applied in 2-3 layers.

Conclusion

Finally, it should be noted that the space under such a staircase can be used as a useful area. For example, on this site it is convenient to arrange a small closet, wardrobe, workplace, or arrange a living corner with an aquarium. And the video in this article will provide more information on this topic.

I bought an unfinished cottage without stairs to the second floor. At first I wanted to hire a master. But I looked for information on the Internet, in principle, you can do it yourself, since I have experience in working with wood.

I just made something similar to the first photo, a ladder and a corner under it.Looks great and very comfortable, saving space to the same. Only of course I had to tinker for a long time and redo it a couple of times, but it was worth it.