The materials for the stairs are one of the factors that determines the final result. Of course, a lot depends on the skill of the manufacturer and on the technology used - but whatever one may say, it will not be possible to realize the full potential of the structure without high-quality wood and modern furniture chemicals.

Which tree to choose for the construction of the stairs, how to process it and from which blanks the main elements should be assembled - you will find answers to all these questions in our article.

Wood is the backbone

Wood requirements

Wood is the main material for self-made stairs. Wooden blanks are quite easily processed with relatively simple equipment, so that the vast majority of craftsmen prefer to work with them.

Naturally, in order for the staircase to end up being reliable, beautiful and durable, the material must meet a number of requirements:

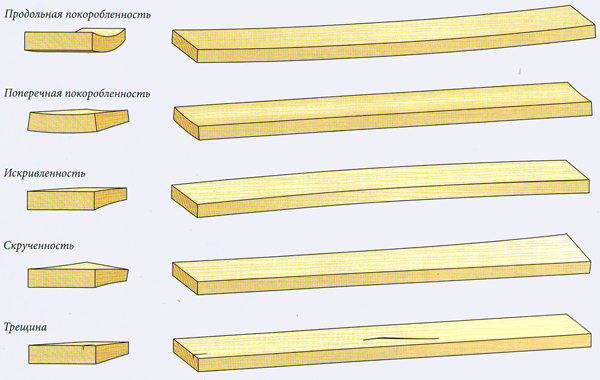

- First of all, the wood used must be of high quality.... It may seem that this is too general a recommendation, but most often quality is understood as the homogeneous structure of wood fibers. Ideal workpieces should be free from knots, cracks, delamination, etc.

- It is important that the ladder material is not damaged during transport.... It is also worth paying attention to the absence of rot or damage by wood-boring beetles. The fewer such defects are found, the better.

Note!

This applies not only to raw materials for the manufacture of stairs indoors, but also blanks for external attached structures.

Even the simplest garden stepladder, made of defective material, will not last you very long!

- Humidity is another parameter that requires close attention.... Only high-quality dried workpieces should be put into operation, the moisture content of which does not exceed 8 - 12%. Damp wood should be pre-dried in a well-ventilated area without direct sunlight.

It is also worth noting the dimensions of the blanks. Ideally, all elements that will be subject to the operational load should be made from a single piece of wood. If this is not possible, you can use glued boards or beams.

Which breed to choose

For making stairs with our own hands, we can use a variety of wood species.

Below we describe in detail those of them that are used most often:

- Pine is the easiest and most affordable material to process. Low hardness will allow you to work with pine even with the simplest tools. The pluses also include wide availability: if you try, you can buy lumber of almost any shape and size.

- If we talk about the disadvantages of pine stairs, then they should include low wear resistance (wood is rather soft) and a tendency to yellowing for several years after installation.

Advice!

It is difficult to deal with the yellow shade of pine, but to prevent its appearance with the help of varnishes with toning pigments is as easy as shelling pears.

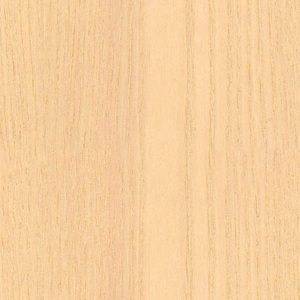

- Birch is a tough wood with a very interesting texture. It is processed somewhat more difficult than pine, but it also lasts immeasurably longer.

- The main problem is the selection of blanks: due to the contrast between the shades of smooth wood and knots, it is very difficult to find large birch boards and beams. In such a situation, craftsmen recommend using veneering - pasting the prefabricated structure with a homogeneous sheet of veneer.

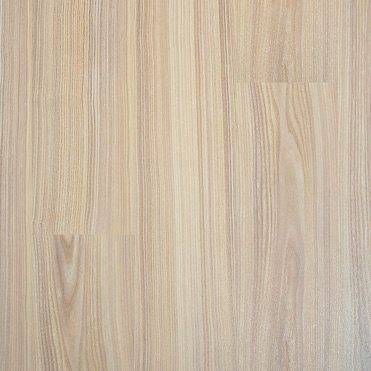

- Beech is one of the best materials for making indoor staircases. Wood is easier to process than oak and has a very attractive color and texture.

- The main disadvantage of beech is that it is "whimsical": with temperature and humidity changes, even workpieces mounted and varnished can be deformed.

- Ash is an ideal material for stair treads due to its high hardness. True, this tree is processed quite difficult, and the variegated texture ash stairs Not everyone likes it.

- Oak. Perhaps only exotic wood species can surpass this wood, since in our latitudes there is simply no way to find a full-fledged alternative to oak. High density, durability, resistance to deformation, noble texture - all these are the arguments in favor of using oak in the construction of stairs.

- The only significant disadvantage is the high price.

Note!

Oak, beech and ash blanks can only be processed with very durable and high-quality tools.

Cheap Chinese saws, chisels and drills will break on solid wood very quickly.

As you can see, there is plenty to choose from. Of course, the final version is largely determined by the financial capabilities and availability of a particular wood in your region. But if you set a goal, then it is quite possible to find quite rare material!

Staircase blanks

Speaking about wood blanks, it should be noted that for each element of the staircase we need a board or timber of a special configuration:

- We make the supporting parts (ladder bowstrings or stringers) from a fairly massive bar or glued board. The thickness of the workpiece must be at least 50 mm, and the width must be from 200 to 300 mm, depending on the configuration of the supporting element.

- The best material for making steps is edged board with a thickness of 30 mm (risers can be made from 20 mm panels). The steps can be either solid (from one board) or composite.

- Handrails, balusters and handrail posts are manufactured using rather sophisticated equipment, so they are most often bought ready-made. Moreover, their dimensions must correspond to those laid down in the project, and the wood must meet all the above requirements.

In addition, for installation, we will definitely need pads, consoles, wedges and other small parts. It is not worth buying them separately: as practice shows, for the manufacture of such elements there are enough scraps of boards and beams.

Concluding the discussion of the construction of the stairs, it is also worth mentioning the fasteners: today, along with mechanical elements (nails, screws, etc.), wood glue is widely used. Modern brands of adhesives provide the connection with a very high strength, so you should not neglect their use..

Decoration Materials

Impregnation for wood

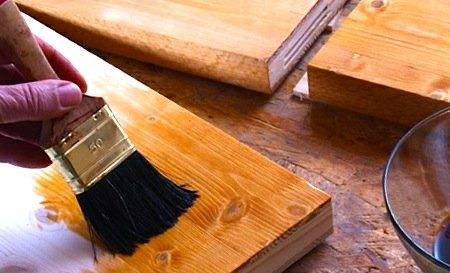

In addition to the basic wooden parts, it is very important to choose effective materials for finishing the stairs. First of all, such materials include impregnations.

Impregnation is a liquid that, when penetrated into wood, gives it certain properties.

Today, the most popular are:

- Fire-fighting compounds (so-called fire retardants). These impregnations provide all wooden parts of stairs with increased resistance to high temperatures.

Note!

Here it is appropriate to speak specifically about increasing fire safety and reducing flammability.

It is hardly possible to completely protect a tree from fire, but it is quite possible to protect a tree from an accidental spark, a falling match or even a small open flame.

- Antiseptics - protect the tree from the effects of bacteria and fungi. Thanks to antiseptic impregnation materials for stairs do not rot even in high humidity conditions (for example, in a bathhouse).

- Complex formulations. Many world-famous manufacturers of paints and varnishes often produce multifunctional impregnations that have not only a disinfecting, but also a tinting effect. As a rule, instructions from the manufacturer contain complete information about the action of the composition and the rules for its use.

Processing of wooden blanks with impregnations is carried out before the installation of the stairs. Thanks to this, we can ensure a uniform application of the substance and achieve its maximum penetration deep into the wood fibers.

Varnishing and painting

Paints and varnishes for wooden stairs are used, as a rule, at the final stage of work.

The exception is the details of the railings, since sometimes balusters and railings are varnished in a disassembled state and only then mounted.

- For painting flights of stairs, alkyd and alkyd-urethane compounds can be used. Preference should be given to precisely those brands that are specially designed for painting stairs, since they include components that provide resistance to friction.

- The enamels can be used to paint handrails, stringers and risers. But for treads, the smooth surface of enamel paints will not be the best option.

- For stairs in the house, the best varnish would be a matte or glossy alcohol-based composition. Let it dry more slowly, but it doesn't smell.

- Exterior staircases can be treated with stronger nitrocellulose compounds. Their specific smell in the fresh air dissipates very quickly.

- As we noted above, for partial masking, or vice versa, contrasting emphasis on wood texture, it is worth using toning pigments. They are added to the layers of varnish, which are applied directly to the wood, and covered with a transparent varnish on top.

The modern assortment of impregnations, varnishes and paints makes it possible not only to extend the service life of a wooden staircase, but also to significantly transform its appearance.

Output

The right material for wooden stairs, which includes both the blanks for the main elements and the finishing components, is a prerequisite for the successful completion of the work.

Of course, an experienced craftsman will be able to handle almost any tree - but it is better to initially purchase high-quality raw materials and stock up on suitable materials. In the video presented in this article, you will find additional information on this topic.

Although pine is an affordable material, I think it is not at all suitable for windows or doors, and even more so for stairs. In general, it quickly loses its appearance, dents appear. Sooooo soft wood. Yes, and varnishes do not really help. Were worn out to restore.

I agree, I also recommend birch to customers, but a little more expensive, but in fact, the operating time of the stairs increases very decently. And in general, if you choose a forest he * ovo - such a staircase will be.