Stairs are one of the most basic structures in houses, since without them it is impossible to move between rooms located at different levels. At the same time, their creation requires the performer to strictly adhere to certain rules so that the final product can function normally, and at the same time be convenient.

Although such simple designs as solid wood stairs can be created even by an amateur.

Work order

The whole manufacturing process is quite simple, but it depends solely on the complexity of the staircase itself, the presence of decorations on it and the type of railings. The richer and more expensive the structure looks, the more you will have to work with it.

Therefore, it is worth remembering that a staircase made of solid wood can look like ordinary steps in a barn or, like a central structure in a ballroom.

Project

Any design should be based on a project.

At the same time, it is especially necessary for flights of stairs, since it is necessary not only to create a full-fledged and functioning product, but also to tie it to the supporting structures.

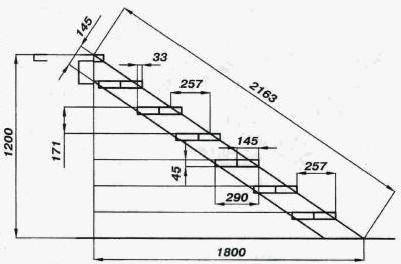

- First of all, the angle of inclination of the product is determined... It is usually believed that it should be 45 degrees, since this is a perfect combination of functionality and space saving. However, if necessary, the rise can be made more gentle, but not less than 25 degrees.

- Next, you need to determine what the height of the steps will be... At the same time, specially developed norms are often used, but professional masters recommend being guided by personal preferences, since there may be elderly people or children in the family, which means it is necessary to adapt to them. (see also the article Width of a staircase in a private house: optimal and minimum dimensions)

- It is believed that stairs and solid wood are the most compatible materials and structures, since they can be given any shape and design.... Therefore, creating a project, you can make the most of your imagination or take ready-made developments, making the necessary changes to them. (see also the article Interior of a hallway with a staircase - ideas and rules)

Advice!

If you do not have a lot of experience in creating such products, then you should not immediately choose complex design solutions.

Even the simplest look of a wooden staircase can look great when finished.

Manufacturing

Getting started, you must adhere to the advice given by the installation instructions, otherwise violations in the production technology can lead to a reduction in the service life and even injury.

- First of all, it should be remembered that dry wood is needed for manufacturing.... Otherwise, after a certain period of time, cracks, chips or places with deformations may appear on the product.

- Self-tapping screws, nails or special wooden cotter pins can be used as a fastening element.... However, it is better if grooves are additionally made at the joints, into which the parts will be mounted.

- If the structure is made by hand, then you should strictly adhere to the project and not make changes to it in the course of work... In this case, you need to constantly use measuring instruments, among which there must be a water level.

Advice!

Any installation is directly related to the project.

Therefore, if the preparatory work is done at the proper level, it will not cause great difficulties and problems.

Finishing

This process depends on what kind of appearance the final product should have. Wooden stairs can be varnished, painted, decorated with decorative elements or impregnated with special compounds. In this case, the final price of the structure will vary depending on the selected processing method.

It must also be remembered that the wood must not be left in its original form. This material is susceptible to moisture and various parasites. Therefore, at least minimal processing must be present.

Advice!

Recently, a lot of excellent tools for working with wood have appeared on the building materials market.

They not only protect the product, but also give it an excellent appearance.

Moreover, the cost of such components fully justifies the funds spent on them.

Output

In the video presented in this article, you will find additional information on this topic. Also, thanks to the text set out above, we can conclude that it is quite simple to create such a structure and even a novice master can do it.

However, it must be remembered that solid wood stairs can have a lot of types and designs. However, some of them are quite complex and require the participation of a specialist or possession of certain skills.

I made myself a staircase in two flights very similar to the one in the article. made from pine. And the guys from metal welded the frame for me. In some places I painted in some places I just left the native color of the tree and varnished everything. It turned out well, but the price tag is affordable. Only for the work on assembling and point balusters, treads, approaches I gave one and a half pieces of greenery. This is without taking into account the cost of the material. And not a beech though.

If you make the main elements (steps, "risers") completely from good material - well, it will come out very expensive. Considering that the top and one end will be "visible", the gluing bars are combined so that one side of the step and the end are "clean", and different defects - on the other, invisible, side and end.