If a person building a country house does not plan to equip it with an elevator, escalator or other device for moving between floors, then sooner or later he will be interested in the question - how much does it cost to make a wooden staircase? The question is far from idle, since the range of prices can be very significant.

It is enough to run through the websites of manufacturers to make sure that very different prices are indicated for structures similar in appearance. What does it consist of and how can you save money when arranging stairs?

Key factors affecting pricing

The cost of wooden stairs, as, indeed, of any other products, consists of three main components:

- Materials (edit)... In our case, this is the type of wood. It is selected depending on the requirements for the appearance of the structure, its durability and price. The most economical are spruce and pine, the most expensive are exotic woods. And the most common in our conditions are ash, oak, beech, larch and other local hard species.

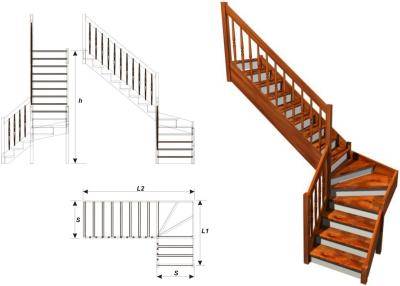

- Construction type and dimensions... The cost of a wooden staircase to the second floor largely depends on the type of supporting base and the method of its fastening. They are selected taking into account its location, expected loads and cross-country ability, requirements for ease of use and safety. It is clear that a straight one-flight design will cost less than a staircase with a turntable or winders.

- Additional structural elements... To move between levels located at different heights, there are enough steps fixed on bowstrings or kosoura. All other elements add to the cost of making a wooden staircase. These include handrails, balusters, platforms, risers. They not only make the structure more functional and comfortable, but also give it a complete design, help to visually connect the staircase with other interior details.

How to reduce the cost of making stairs

Each developer has its own priorities and financial capabilities, and for many, the issue of reducing the cost of certain structures is relevant. Some decide to do some of the work with their own hands, others are considering other possibilities.

If we are talking about the device of the stairs, then there are three options: custom-made, the acquisition of a standard design with fitting in place, and wood-cladding of the frame made of other materials. Which one is more profitable?

Typical designs

The least costly method, especially if the type of structure and its dimensions are known in advance, and the project was created taking into account these dimensions. The production of typical stairs itself is the most technologically advanced and therefore less expensive.

Note. Many manufacturers produce individual elements, from which, like from a designer, stairs of different sizes and configurations can be assembled. You can do this yourself, since the kit comes with clear and detailed instructions.

Frame cladding

To reduce the cost of manufacturing wooden stairs, sometimes they resort to a frame made of metal or monolithic concrete.

However, you can save on this only in two cases:

- If the frame was made by experienced specialists who know the technology of subsequent veneering and take it into account. Otherwise, alterations and adjustments will only lead to an increase in the cost of work;

- If the cladding will consist only in the installation of wooden steps.

The device of a concrete or metal base is not much cheaper than a wooden one, and together with a full cladding to give the staircase a wooden look, it will cost you even more.

For reference. In fairness, it must be said that such designs are considered more practical, because have better strength and durability. Unlike fully wooden staircases, they do not start to creak over time.

Manufacturing according to an individual project

Of course, if the financial issue is not acute, any person will prefer not a standard, but an individual option for decorating their home. But even in this case, you need to know how much a wooden staircase to the second floor costs, what costs will be mandatory, and which can be avoided.

The first expense item will be the creation of an individual project, in which all design solutions must be calculated, details drawn, materials used, etc.

To create a project, the customer will need the following data:

- Floor height - the distance between the clean floor of the lower and upper levels;

- Staircase width;

- Construction type: straight, with a turn (900, 1800), with a platform or winders, screw, etc .;

- Height of fences;

- Manufacturing material;

- The need for finishing (toning, varnishing) and installation.

In the video presented in this article, you will find additional information on this topic.