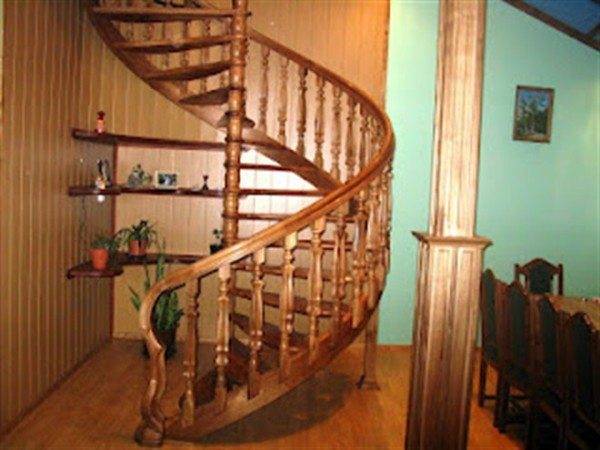

During the construction of houses, one often has to deal with the need to manufacture stairs of various configurations. And the more intricate the design is in execution, the more diverse and more various constituent elements are used for its manufacture.

Sophisticated wooden staircase railings of this type constitute the main cost of the entire structure. To the cost of the material, you can add the cost of paying for the services of a master manufacturer.

The essence of wooden fences

Ladders come in different designs and are designed for different purposes. Among them:

- entrance stairs to the veranda;

- to the attic (example - Oman stairs for attic spaces);

- to the site in front of the entrance;

- outdoor;

- interfloor;

- to the basement, etc.

It is quite possible to buy a ready-made structure of a factory production: a tolerable price can be a determining factor. However, such a staircase is unlikely to fit into the interior of your room. We recommend an individual approach to this issue.

The beauty of stairs, by and large, it is determined by their fences, which must be architecturally expressive and durable. The disadvantages of the flight of stairs and some steps can be covered with a carpet, but the railings are always visible. Their appearance gives a general impression of the entire structure as a whole.

Turning options

For the interior, great importance is attached to:

- the beginning of the fence;

- his turns on the sites.

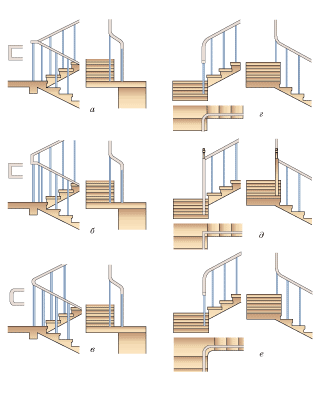

There are three options for turning the railing of two-flight type stairs180 °:

- The line of the handrails of the upward march reaches the intersection with the handrail of the downward march, in the interval between the flights it is conducted horizontally. This is done in the case when the railing on the site is clearly moved away from the edge and therefore goes beyond the intersection of the two lines of the marching railing.

- A fence for stairs made of wood with a handrail line reaches the platform and there it takes the position of the horizon, then turns and slides up (or down) to the line of the next march.

- The last option is that the lines of the handrails are not brought to the intersection, but at a small distance from the edge of the landing, they are drawn along a curved line from the bottom to the top element.

Rotated 90 ° difficulty arises due to the difference in the heights of the two steps in the place where the platform intersects with the march. Here you will need to install a special fitting (d), which will connect the railing along a curve.

Or you can put the support baluster in the place where the handrails intersect (e). The railing will rest against this element from different sides at different heights. In structures with an extended version of the platform (e), the problem with the intersection of the handrails is solved by the curved smooth bending of this element or the setting of the fitting.

Handrails

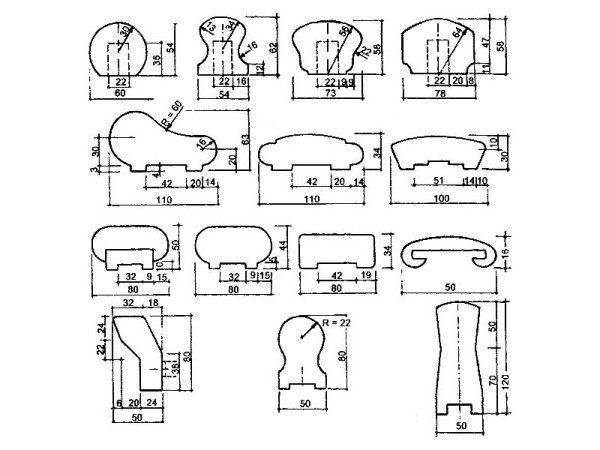

The handrails serve as handholds and, together with ordinary balusters and support posts, give rigidity to the entire staircase. Their dimensions and profile must strictly correspond to the dimensions of ordinary and support balusters.

The material for handrails is usually:

- full-length glued wood (at least two-layer);

- with a handrail length of more than 3 meters, transverse gluing is also done.

The groove that is made in the lower part of the product must correspond to the dimensions of the section of the support element of the balusters. If the balusters end in a round section, they are fixed in the holes drilled in the lower part.

Purchased handrails come in different lengths - from 250 to 350 cm, or they are made to order (this depends on the size of the balusters and posts).

The handrails are made on a woodworking milling machine. At home, a curly sample product can be made with your own hands on an ordinary staging machine, the straight cutters of which are changed to profile ones.

- First, a glued "blank" of the handrail is made from veneer from 1 to 5 mm thick, which is clamped with clamps until the glue is completely dry.

- After that, they give it the desired profile on the machine and grind it with a little foot.

Advice! The use of solid wood for the production of handrails (bowstrings, stringers, steps) is not recommended. Curly fibers, knots and uneven drying of the wood can damage the wood product.

Railings for stairs made of wood have additional elements in the railing: decorative and swivel fittings, which are purchased separately or made to order. All these fittings have the configuration and dimensional characteristics of the profile similar to the handrail.

Support posts and balusters

Support pillars (starting, corner, finishing balusters) are an important component that ensures the rigidity of wooden fences. Blanks for these elements are glued from at least two longitudinal parts. Solid wood posts will subsequently crack or deform, which is unacceptable.

If you are planning to install wooden railings for stairs with a classic shape of turned supports and a final ball, you need to pay special attention to the square part of the post (its length). It should clearly adhere to the support rail of the handrail on both sides at different heights.

Standard posts have the following dimensions:

- height - 100 - 130 cm;

- with a section - 120 x 120 or 70 x 70 mm - it must exceed or be equal to the width of the handrail.

Row balusters can be of any thickness - they are not load-bearing, therefore, they perform only a protective and decorative function. However, the ordinary supports must be secured sufficiently firmly in the stair treads and handrail.

The usual size of common type balusters ranges:

- thickness - 30 - 80 mm;

- height - 80 - 90 cm.

Balusters are fixed at two points:

- into the handrail sample from above (hole or groove);

- in the sub-rail or step from the bottom:

- In the first case, a fixing block is inserted between the balusters (it is either nailed with "hatless" nails, or glued).

- The lower part of the baluster cuts into the steps, while fixing it with hardware. Or, similar to the upper version, it is inserted into the sub-rail and reinforced with fixing bars.

The support rail is a profile corresponding to the handrail, with exactly the same groove for attaching balusters. It is also used as an expander if wooden stair railings are equipped with balusters that exceed the size of the bowstring.

Balusters are connected with props in the same way as with handrails:

- install sub-rails;

- then balusters;

- put a handrail on top.

In conclusion

On our portal there is more detailed material on the topic of stair railings and their installation. Instructions from professionals will help any novice master, becoming a useful help. In the video presented - in this article - you will find additional information on this topic.