In the manufacture and installation of stairs, builders often face a problem in the form of a lack of space. An excellent solution is wooden staircases with winding steps. To make them yourself, you need to know some of the nuances, which we will discuss below.

General information

It should be said right away that the run-in steps cannot be considered as a separate element of the structure, since their application determines the general structure of the product. As a rule, wooden staircases are complex in design. Instead of a traditional platform, they have a smooth turn.

In this case, the norms of the tread are observed only along the middle line, while the inner edge is narrow. As mentioned above, run-in steps are made for the sake of saving space in the room.

They can be installed anywhere - both along the wall and right in the middle of the room. From the point of view of convenience and compactness, this is the most optimal option.

However, wherever there are pluses, there are also minuses. Winder stairs in this sense are no exception.

Their disadvantages include:

- steep climb;

- narrow steps;

- the complexity of the calculations;

- laborious manufacturing process.

Before you start working on the structure, you will have a difficult choice: make the calculations and make the stairs yourself, or buy a ready-to-install structure.

If you want to purchase a finished product, then you should consider the following nuances:

- It will still have to be adjusted to the specific dimensions of your room. In most cases, this process requires more time and effort than making it yourself;

- The finished product is not always made of quality materials;

- The price for a finished staircase is incomparably higher than for the material from which you can make a staircase yourself.

It follows from this that it is much more expedient to take up the manufacture of a staircase structure on your own, if, of course, you have at least a little experience in working with wood.

Making stairs

Materials (edit)

For the manufacture of stairs, before performing all the calculations, you will need to decide on the material. It is best to use hardwood. An excellent option would be an oak staircase.

The woody structure of the oak structure looks great with almost any interior. And if desired, it can be painted in any color to give the design originality. However, ash, as well as other types of wood, can be used.

Calculation of the winder ladder

For an example of calculation, let's take a staircase that has two parallel flights with a turn made using winder steps.

First of all, the future staircase must be created on paper. To calculate, you first need to draw two marches. In the center of the march, it is necessary to draw a line ABC - this is the middle line of movement, in accordance with which the width of the steps is applied.

The line must be drawn from the rounded top so that the step located in the middle is halved by the BC line (sketch a in the diagram). Thus, ordinal divisions are obtained.

Advice! The greater the number of straight steps, the more comfortable the staircase will be, and the transition to the winder steps is smoother.

Then it is necessary to draw the DE line horizontally, capturing three straight steps, enclosing the highest one. From it, the regulation of the step width will begin, connecting two lines on the line of movement with the middle A.

After drawing the line until the lines intersect with the DE line and the next segment is obtained, it must be continued from point D to E, until the next points are obtained. The obtained points should be connected with the corresponding lines according to the number value, which are marked along the line of movement.

The result of such calculations is a horizontal projection of the shape of the staircase steps on the left side. The right side is calculated in the same way.

In addition, when independently calculating the winders, the following points must be taken into account:

- The width of the step should not exceed 40 cm;

- The radius of curvature must be more than 30 cm;

- The staircase must be smooth and follow the direction of the flight of stairs. Excessive curvature of the travel line is unacceptable.

- The structure must necessarily ensure safety, comfortable lifting and comply with established standards. When designing, special attention should be paid to the height of the steps. Low steps are uncomfortable and dangerous, while steps that are too high make it difficult to climb.

The calculation of the beams is very simple to do, using the Pythagorean law for this - the square of the hypotenuse is equal to the sum of the squares of the legs. To the resulting figure, you need to add about 30 centimeters.

Tool

When creating a staircase, you will need the following set of tools:

- Drill;

- Jigsaw;

- Screwdriver;

- Self-tapping screws;

- Roulette;

- Hammer.

Manufacturing and installation of the structure

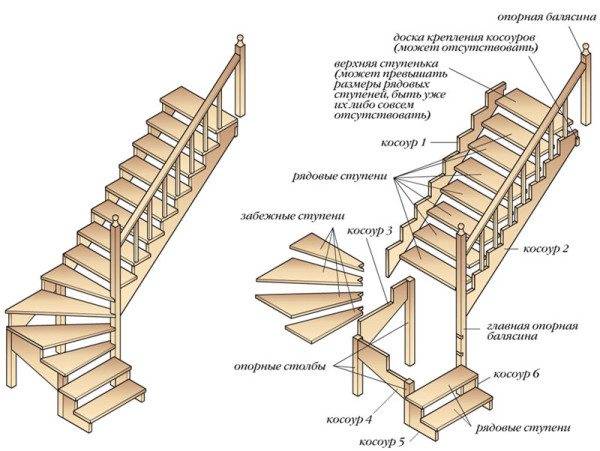

Wooden ladder with do-it-yourself winders can be made of two types - on bowstrings or kosoura. The most common option is the first type - on bowstrings. In this case, the elements made in accordance with the calculations are cut into the load-bearing base, i.e. the bowstring, and the bowstring itself remains in sight.

It is a little more difficult to make a staircase on kosoura, since it is necessary to make rectangular cutouts in the load-bearing beams, on which the steps will fit. A design of this type turns out to be wider, while the stringers are hidden, and only steps and risers remain in sight.

If aesthetics and conciseness are in the first place for you, then it is better to give preference to kosoura. To do this, you will need two beams with a section of 100 * 200 mm. The most important thing is to correctly mark the beams and make the same cuts on them, since this will determine how even the steps will lie.

If the run-in part is located at the base of the stairs, then the steps are mounted on load-bearing pillars and risers. In all other cases, the structure is conventionally divided into three parts - before the race, the cross-country steps and after the race. The pivot must be mounted in the middle.

When the race is located in the middle, the turning steps are mounted on beams. It is much easier to mount straight beams at right angles, without curly "twists". If you want to make a rounding, then a piece of plywood can be bent at the place of the bend of the running staircase.

Advice! To bend the plywood, the sheet can be placed at the edges on two tables so that the main part of it sags. A load is placed in the center, and the sheet itself is poured on both sides with water. The plywood should be in this position until the sheet reaches the desired angle.

Also, when turning the structure 180 degrees, three beams can be used for a race. However, although the use of plywood is more difficult to install, it will make the stairs more beautiful. At the same time, in both the first and second cases, all the shortcomings can be hidden behind a drywall box.

Advice! In order for the flight of stairs to fit well into the allotted space, the profile of the stairs should be drawn on the wall. If necessary, you can correct the dimensions of the steps.

Most often, the installation of the stairs begins with the installation of the first part. Then beams are mounted, which will hold the structure in weight. Before installation, all parts must be carefully sanded, and the outer edges can be rounded for beauty.

When the main part of the structure is installed, it remains only to mount the balusters on the steps. They can be secured with a 100 mm long and 8 mm thick stud. Railings are installed on top.

This completes the installation instructions. It remains only to paint the structure. So that the wood is well preserved and at the same time its natural beauty is not lost, you can use transparent varnish as a coating.

Output

With your own hand-made staircase, you can get a reliable structure that will fully suit your home. At the same time, you will significantly save finances. However, without certain skills in woodworking, it is unlikely that you will be able to do this job.

For more information on creating winders, see the video in this article.