In low-rise suburban construction, they often resort to solutions that save space and prevent excessive load on the floors. So, if there is little space left in the house, the owners usually look for a compromise - they assemble a screw structure or resort to making a goose step staircase with their own hands.

Such a ladder looks funny and it is thanks to the shape of the steps and the manner of movement along it that it got its name.

Description of the stairs goose step

In this case, we are talking about small and narrow models that have a symmetrical half-step shape: where each subsequent one has a cutout exactly above the place of the protrusion of the previous one. Such an original solution also has other names - for example, duck step, duck's foot, moth ladder (the steps resemble butterfly wings from above).

But basically the steps follow the shape of a goose's paw. Another name from the Latin American dance "samba", because, going down or up the steps, it is simply impossible to miss or confuse the order of the step.

Interesting fact!

A similar design was invented by European craftsmen of the 10-11 centuries: at that time it was especially important to construct a span in narrow towers, in mills and bell towers.

Due to the fact that most often the goose step of the staircase was found precisely in church institutions, it was dubbed the "monk's staircase."

Distinctive design features

The expediency of this design solution is not always justified, for example, if the width between the load-bearing walls and the floor beams is large enough, you can use the usual version with double railings and gentle marches. But where the footage of the room is small, and it is somehow necessary to get to the next floor, this steep symmetrical ladder is made.

Typically, the inclination of the steps is between 45 and 65 degrees. The only alternative to such a staircase is a spiral staircase made of wood or metal, but its inconvenience lies in the steepness of the march, and if small children or pets live in the house, there is a risk of injury when going down the stairs.

The advantages of a ladder are that even with a high step, the probability of stumbling is very low, since under the notch you can see the wide part of the lower step from where the leg rises. The risk of injury is minimal for both the elderly person and the child.

Stage 1. Design features

Since, when moving up and down, we for the most part (excluding very small children) step on one step with one foot, then only one part of this step - the left or right should have sufficient width to receive the foot.

This shows a drawing of a staircase with a goose step, at which the typical angle of inclination and length of the step are calculated. Usually, the second half is made as narrow as possible in order to only withstand the load from a person's weight.

From which side the ladder begins to miscalculate is not important, but usually the first step is made to the right side, since 95% of the world's population is right-handed. The first step has a great influence on the calculation of the goose step ladder; it must have either a solid surface in area or a base increased in thickness.

This is especially true for fashionable glass staircases: experts advise to make the first step of compacted glass completely, without the "goose-shaped".

The next step is to choose the side of the staircase, because we are talking about a small screw rounding. To be able to match it with the step of the foot, the turn should go away from the support step, so you do not have to pirouette while walking. (see also Staircase to the second floor)

When it comes to a straight structure, a staircase with a goose step can have a higher step mark, due to this, the width of the steps can be reduced.

Stage 2. Material selection

Most often, three types of designs are used:

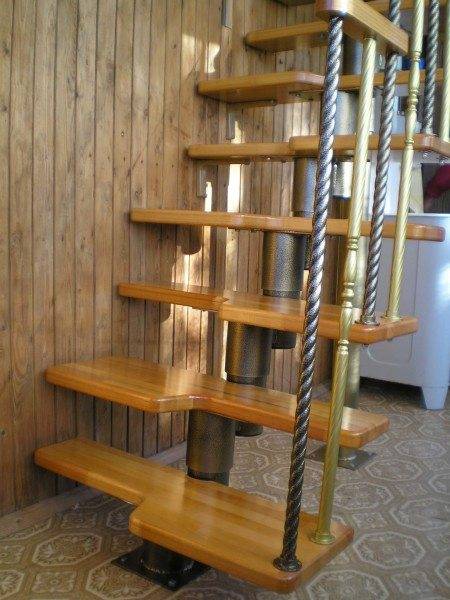

- Solid hewn wooden ladders (see also Wooden ladders);

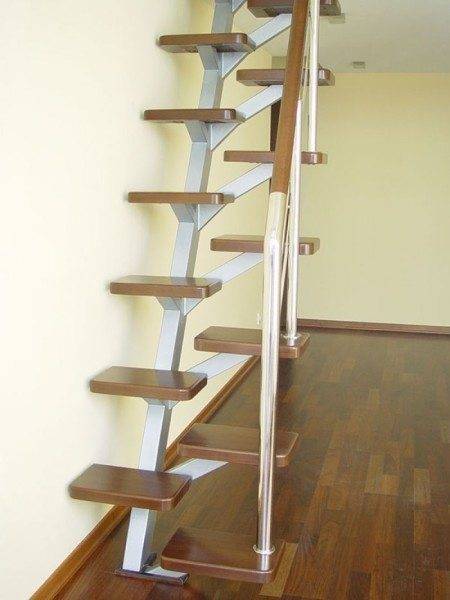

- Metal, made according to the screw principle;

- Glass staircase crow's feet.

It is also proposed to combine a couple of elements in order to save money. So, stairs with a metal frame and wooden or glass steps are popular in suburban housing construction.

Elements of railings and supports play a special role here: if you make them in a forged version of blackened metal to match bronze and combine with smoky frosted glass, you get an airy ensemble like a bean stalk from a fairy tale going into the sky.

Please note that when building a wooden staircase, all parts are ordered at the sawmill. Before assembly, they will need to be treated with a fire retardant and moisture and mold protection agents. This can be done at home, then leave to dry in the open air for a day and open with varnish.

Stage 3. Design calculations

A small instruction will help you calculate the step and step length indicators for your home:

- Start with the first step, the location of which, if it has a half-shape, directs the wide part away from the turn of the stairs... For example, if the structure is twisted to the right, the step has an extension under the left leg, etc .;

- To ensure the comfort of the step, the steps of the stairs are treading at least 2/3 of the length of the foot of an adult (17-20 cm)... The total length of the step is 25-30 cm;

- The cut that passes to the tapered part must have a rounded or oblique shape, this reduces the risk of injury and twisting of the leg while descending.

The price of the structure depends on the choice of materials, the span length and the parameters of one step.

It is also influenced by the following design rules:

- The steeper the turn of the staircase, the more you can cut the width of the step in the pivot point. For straight structures, it is advised to leave the standard parameter of 300 mm;

- When choosing a spiral shape for a flight of stairs, use the "corkscrew" angle calculation. So, to calculate the length of a structure with a full revolution of 360 °, the length is calculated as L = 2πR. We subtract exactly a quarter from the construction with a revolution of 270 °, as a result, the length is L = 3πR / 2. Etc;

- If metal is chosen as the material, then the narrow part can be omitted altogether by welding the "half steps" to the base-frame like pedals. In wooden and glass structures, such a solution is not very acceptable;

- Risers are used occasionally, in a wooden structure;

- The step size between steps should be slightly increased. Builders call the step height of 150 mm the most successful for a staircase with a turn.

Advice!

When choosing a coating for wooden steps, it is better to use a matte varnish so that there is no risk of slipping on the glossy finish.

conclusions

This rather amusing and at the same time convenient design can be used not only as the main one inside a country house, but also as a basement, outdoor and decorative staircase. Its main advantage is the continuous saving of space, material and labor costs for its manufacture.

You will find more information on this topic in the video presented in this article.