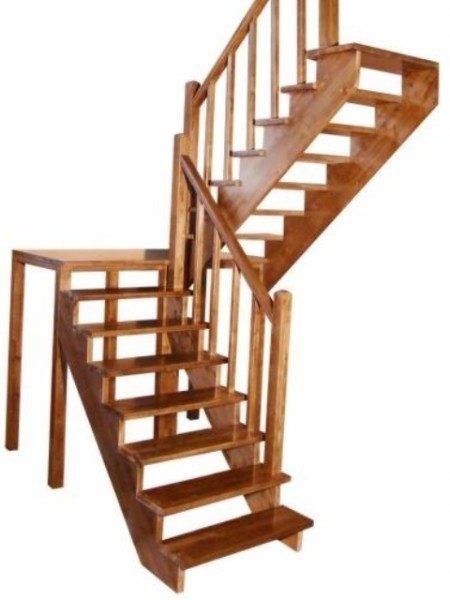

All the available variety of stairs for a private house can be divided into 3 main groups. These are sustainer, screw and combined designs. The most popular among them is the first type.

It includes such an interesting subspecies as a 180 degree swivel staircase. We will now tell you about its varieties and the technology of its creation.

general characteristics

This item is placed in openings that have a rectangular shape, close to square. For example, it can be a notch measuring 180x200 centimeters.

The 180º rotation can be done in different ways:

- by using a small rectangular staircase... She divides the entire structure into two parts, called marches. The platform is mounted in the staircase and marching stairs extend up and down from it. Such a product is easy to install, but takes up a lot of space;

- the use of winder stairs Is the next way to turn. It saves space and makes the appearance more aesthetic;

- use of a semi-screw type of construction - it gives the stairs an elegance. But, at the same time, such a product is difficult to manufacture and its price is quite high;

- combined options - there may be cases when both the platform and the winders are used for turning.

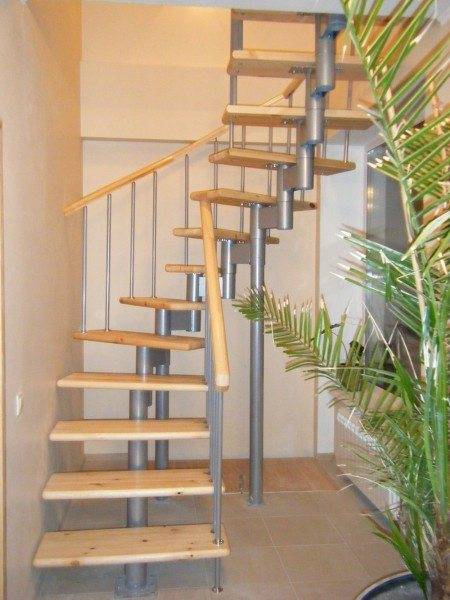

Recently, modular staircases with a turn of 180 have become quite a popular type of such structures. They consist of module elements. Thanks to this, they can be assembled easily and quickly like a construction set for children.

The steps in the modules are made of pine using a special technology. With its help, their service life is significantly increased. In addition, such parts are less subject to deformation.

Rotation 180 degrees in modular designs is achieved in the same way as described above. But most often the site is used for this.

The advantage of such a product, in addition to the ease of assembly, is the ease of configuration. That is, the proposed planning solutions can be combined in different ways. This allows you to fit such a thing into any interior.

A modular staircase with a 180 degree turn is assembled from metal elements. During assembly, they are inserted into each other and fixed in this position.

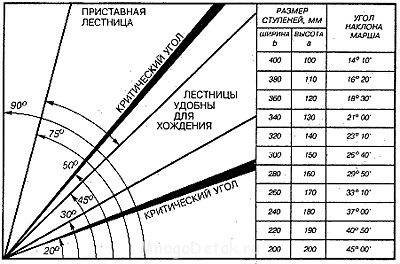

The design of the modules allows you to create versatile ladders. In them, if necessary, you can increase or decrease the height. You can also set a different angle of inclination of the structure. Its magnitude can range from 35 to 45 degrees.

There are various versions of such products on the market. Depending on the technical characteristics and brand of the manufacturer, a universal set of stairs with a turn of 180 degrees can have very different prices. It can range from several tens to several hundred thousand rubles.

Making a staircase with a turn

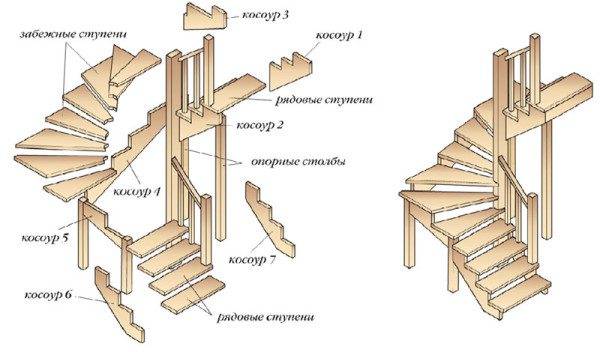

First of all, you need to know that any staircase structure consists of the following main elements:

- support beams - can be in the form of a stringer, a ladder string or a pillar. They are the supporting element of the entire product;

- steps - consist of an upper plane, which is called a "tread" and a side part, called a "riser";

- railings - they consist of an upper element - a handrail and supporting parts - balusters.

Design

The first and very important stage of work is design.

In the course of it, first of all, we must answer the following basic questions:

- what will be the height of our stairs;

- what should be its width;

- what will be the width of the steps; (see also the article Stair tread width norm, as well as other standards for its characteristics)

- what should be the height of the riser;

- what will be the angle of inclination of the staircase.

Let's start the calculation of a 180-degree pivot staircase with the answer to the first question. To do this, manually, using a tape measure, we will measure the required height of the future product.

To answer the next three questions, let's take a look at the calculations.

To determine the required step width and riser height, use one of the following formulas:

- 2a + b = 64 centimeters;

- a + b = 47 centimeters;

Wherein:

- a is the height of the riser;

- b - indicates the width of the step.

Let's say the parameter "a" is equal to 12 centimeters. Based on the first formula, we get: 2 * 12 + b = 64cm. Hence b = 64-2 * 12 As a result, the width of the step is 40 cm.

But this is too much. Therefore, here you can use the formula number two. From it we get: 12 + b = 47 cm.Total, b = 35

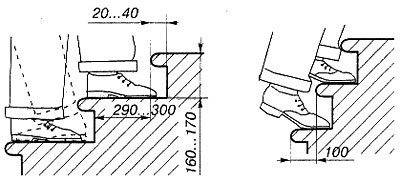

Practice shows that the most convenient are those stairs in which the height of the steps is from 14 cm to 17 cm, and the width is from 29 cm to 35 cm.In general, the first parameter should be in the range from 12 cm to 20 cm. The second must be equal to or greater than the first.

Advice!

When designing 180-degree pivot stairs, do not make the height of the steps more than their width.

It will be simply uncomfortable to walk on such a ladder.

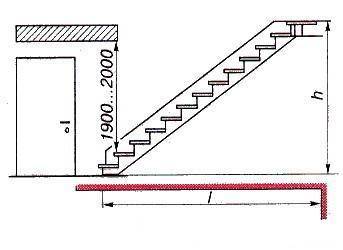

Do not forget about the distance from our product to other structures located above. The available space to the ceiling must be at least 1900 millimeters.

The width and height of the steps can be determined in another way. To do this, use the table below.

The total width of the stairs is usually between 1m and 1.5m. For a private house, it is not worth doing wider.

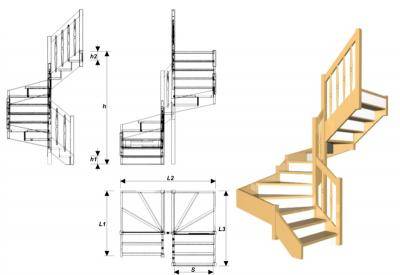

If you decide to calculate a staircase with a turn of 180 degrees, in the design of which the run-in steps will be used, then in the process of further design we do the following:

- We draw a circle, the radius of which is equal to the width of the stairs plus ½ the distance available between the flights of stairs. Alternatively, you can take a radius equal to 1.13 times the width;

- Further, on one and the other side of the circle, we draw straight marches with a predetermined width and length. After that, through the middle of the marches, we draw a line of movement and mark straight steps;

- Then, through the highest point of the circle and its center, draw a line up to the lowest point of the circle. The resulting segment is designated as BC. It must necessarily pass through the middle of the central winder. It will appear first, and it is from it that the steps will be counted;

- The last straight step is denoted by the segment DE. After that, we draw the rest of the winders from the central winder.

Manufacturing and assembly of structural elements

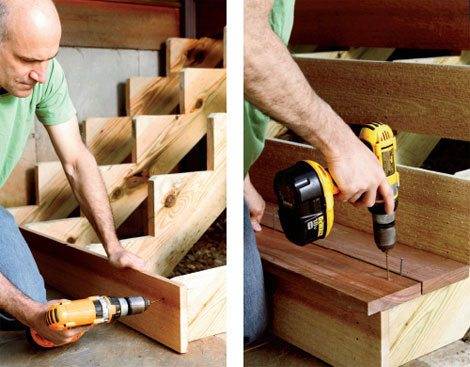

For convenience in work, it is worth making a pattern with your own hands. With its help, we will mark the stringers. They will need 3-4 pieces. This amount will be quite enough to ensure the strength of the entire structure.

Having marked out the stringers, we proceed to cutting the teeth. To do this, take an electric jigsaw or an ordinary hand saw. In the process of work, you should be careful and accurate in order not to allow the cut to go beyond the marking lines. The resulting part can be used as a template for the rest of the stringers.

Having finished with the process of cutting these blanks, we remove the chamfer from their corners. This is done in those places where the step and riser will be adjacent. This is necessary for more reliable contact of parts with each other.

The next step in our work will be cutting out steps and risers. In the process of work, do not forget to take into account the thickness of the riser, as well as the fact that the tread has a protrusion of 2-4 centimeters above it.

Having prepared these parts, we fasten them with nails or self-tapping screws.To do this, we will use a screwdriver or drill.

After completing the installation of the steps, we proceed to the installation of balusters and handrails. They are needed to ensure safety when going down and up stairs.

As the final stage of work, our instructions provide for the application of paintwork. It will protect the surface of the erected structure from adverse external influences.

Output

Stairs with a turn of 180º are placed in interfloor openings that have a rectangular shape. The turn is realized with the help of winders, a landing or a semi-screw type of construction. Combined options can also be used.

Having decided to acquire such a design at home, you can buy a ready-made modular version of such a product. Or contact a private company with an order.

It should be noted that it is quite possible for a home craftsman to make a turning staircase. The design and assembly guidelines outlined above will help you get it right.

For clarity, you can watch the video available on our website. In the video presented in this article, you will find additional information on this topic.