The staircase is the most important structure in the house. To create it, it is necessary to follow a number of specific rules so that the final product is not only functional and safe, but also has a good appearance. That is why the question of how to make a staircase in a house yourself is very popular among novice builders.

Work order

Before proceeding with the manufacture of this structure, it is necessary to decide on what material it will be made of. You also need to draw up a sketch of the appearance of the entire device in advance.

At the same time, many instructions on how to make a metal staircase yourself suggest dividing all the work into different stages, which require a separate approach.

Project creation

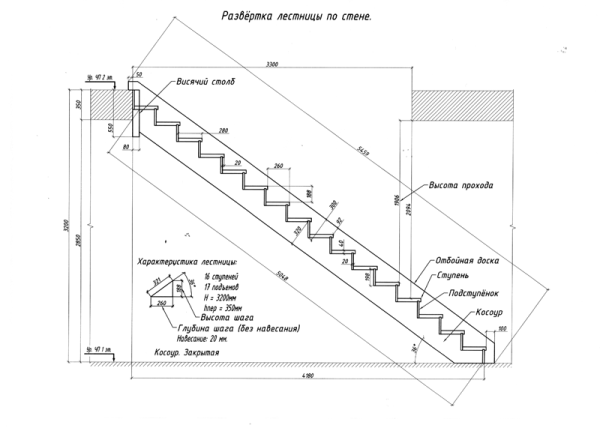

This stage can be called the main one, since the entire structure depends on it, from its dimensions to design.

- First of all, you need to choose a material. It depends only on the personal preferences of the customer, although many manuals telling about how to make the staircase yourself in the country, I advise you to make staircases from reinforced concrete, and the railings from metal or wrought iron. This recommendation is due to the fact that this material is one of the most practical and does not require much maintenance, and if desired, such a structure can be sewn up with wood.

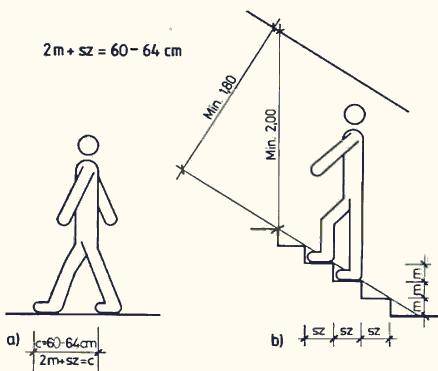

- Next, you need to determine the angle of inclination of the structure. For small houses, it is best to do it under 45 degreesas this will help save interior space.

- Then you need to choose the height of the steps of the stairs. Typically, a DIY ladder assumes the use of generally accepted standards, but professionals advise to do so based on personal preference. This is due to the fact that there may be elderly people or children in the family who are not very comfortable with the typical step-up.

- In the last place, they are engaged in the design of the structure. To facilitate this process, you can use ready-made projects or photographs.

Advice! The main criterion for designing a staircase is its convenience and safety. You should not create beautiful products that will make it difficult to climb or can lead to injury.

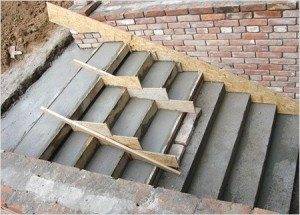

Formwork and reinforcement

When we make the stairs ourselves, and especially the formwork for it, it is necessary to observe safety precautions and use additional supports, since the entire structure will not only have an impressive weight, but also a large size, some of which will be at a height.

- It is best to use moisture-resistant plywood as a material, from which the entire frame will need to be assembled.

- To support it, ordinary logs or beams are used. Moreover, if the structure involves the creation of concrete supports, then it must also be fixed.

- After the formwork has been created, the installation instructions recommend covering the bottom with an oilcloth. This is necessary so that cement does not flow out of the solution along with moisture.

- Next, you need to place the reinforcement. In this case, you can use special stands that will control the distance from the metal to the edge of the product.

- It is worth noting that when placing reinforcement, it must be tied to supporting structures or to the floor.Also, a manual on how to make a railing for a staircase yourself, advises to bring some of the metal to the edge of the span, so that after pouring small pieces stick out of the product for attaching the fences to them.

Advice! When tying reinforcement, it is better to use welding, since in this case all the elements must be rigidly connected.

Fill

Some tutorials that tell you how to make the staircase to the attic yourself recommend pouring it in stages, first creating the substrate, and then the steps. However, such an action is not justified by anything and creates additional problems during installation. That is why the whole process is best done so that a monolithic structure is obtained.

After the mortar has filled the formwork, a special vibrator can be used, which positions it evenly over the entire form and helps to remove air bubbles. When the surface seizes, then to speed up the hardening process, you can put a rag soaked in ammonia solution on it and cover with a film. These materials are usually inexpensive, and their ability to draw out moisture will help cut drying in half.

Advice! It is best to do the pouring together with the installation of the floor. Especially if it is made in the same way. This will not only simplify the work, but also allow you to get a monolithic structure.

Fences and railings

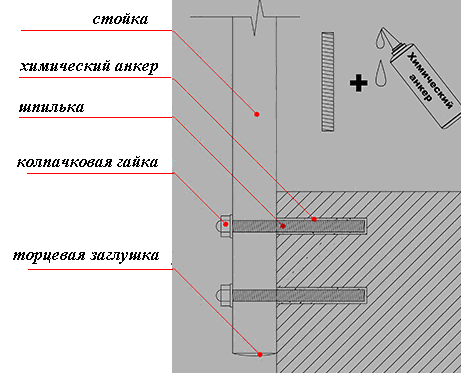

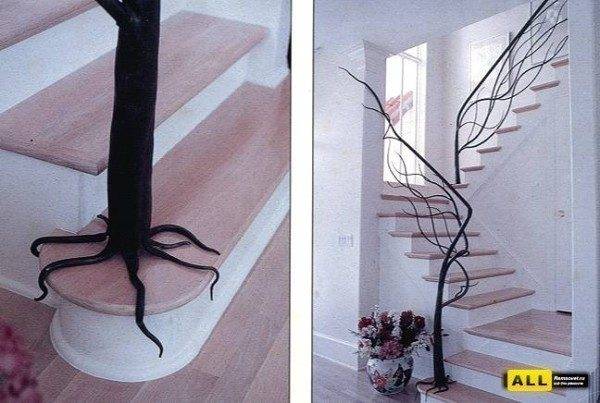

When deciding how to assemble the ladder yourself, special attention should be paid to the railing. They can be made independently, but when choosing a forged structure, the need for certain skills will arise. Therefore, it is easier to order such a fence from a specialist.

It is worth noting that in the modern markets of building materials, you can purchase similar products of any shape and configuration. However, professionals advise making such a purchase in advance, so that before pouring, you can prepare the elements for fastening in accordance with the required dimensions.

Installation of fences is carried out by welding them with protruding fittings. You can also use special connectors. If the installation is done by hand, then it must be borne in mind that the best fixation involves the presence of support points in several planes, which means you need to think about fastening to the walls or the side of the staircase.

Advice! Installation of this type uses a welding machine, which is a source of high temperatures and fire, and given that the work is carried out mainly indoors, all safety standards should be taken into account when using this device.

Sheathing

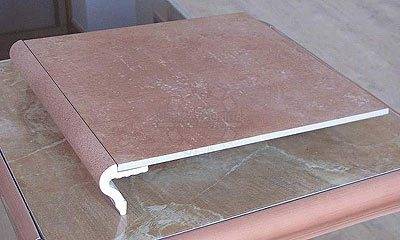

After all the fences and railings are installed, you can do the cladding. For this, you can use any available material. However, you need to think in advance about how to attach it.

Many guides that tell you how to make an attic staircase and similar structures yourself suggest providing for underfloor installation in advance and, when pouring, mutilate the necessary strips or fasteners into concrete. In this case, glue-cement, planting plaster or special dowels are also used.

Advice! For a concrete staircase with wrought iron railings, it is better to use natural stone tiles or tiles. So the design will get a stunning appearance, and installation will not cause big problems.

However, it is worth remembering that there are many options for such structures, which differ in appearance, material and technical characteristics.Therefore, before starting work, you need to choose a specific type of product (read also about the advantages of glass stairs).