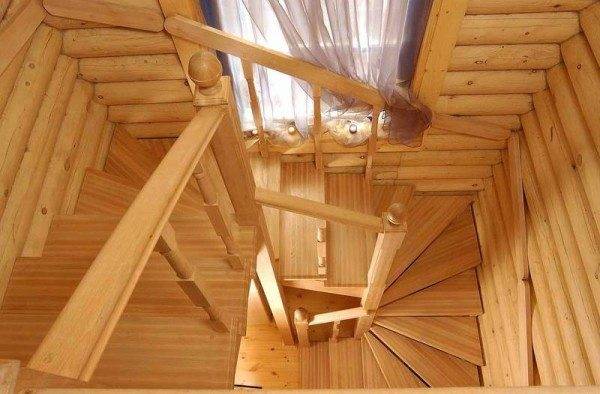

The staircase in the house is not only a way of connecting two floors, but also a major element of the interior. Currently, there are a great many different staircase designs. But a special place among them is occupied by screw products.

These are objects that are very difficult to design and manufacture. Therefore, if possible, it is better to order such a design from a specialized company.

The craftsmen will make an accurate calculation and create such a staircase in accordance with all standards. Remember that any mistake during project design or implementation can be costly later on.

If you are confident in your carpentry skills and you have enough free time, then you can create such a product yourself. How to make a spiral staircase correctly, you will learn from our article.

General characteristics of spiral staircases

Dignity

This building has undeniable advantages:

- compactness - the screw design takes up little space;

- economical consumption of material - it will be required much less than in the case of a marching type of products;

- original appearance - this building can become a real decoration for your home interior.

disadvantages

The cons of these designs are as follows:

- little functionality - such a staircase will not allow bringing in furniture or large household appliances;

- difficulty in use - It is more difficult to walk in a spiral than in a straight line. Therefore, even at the design stage, you need to carefully consider the ergonomics that a homemade spiral staircase will have. First of all, pay attention to the size and number of steps, as well as the convenience and reliability of the handrail.

Basic types of construction

Depending on the shape, there are 2 types of such a product:

- polygonal - such buildings repeat the configuration of the walls of the room. The steps are interconnected with a straight or spiral bowstring. Kosour or bolets can also be applied. In this case, the railings, along with the pillar, are a supporting structure that gives rigidity to the entire building;

- rounded - in it, the steps are located radially and are attached to the support pillar. They are connected to each other using a spiral bowstring or bolts.

Materials for making

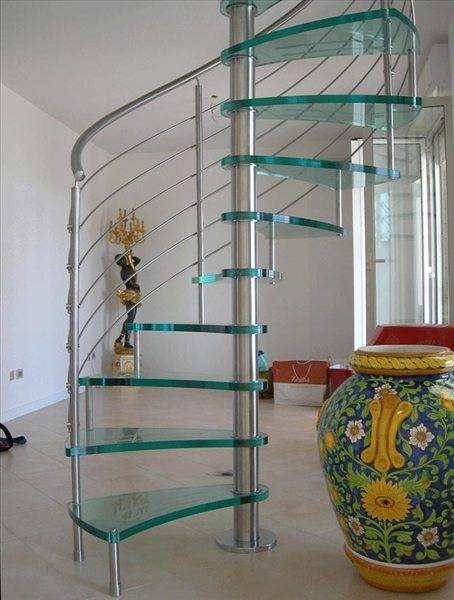

Spiral stair treads are usually made of hardwood. Staircase steps can be made of oak, maple or cedar. The most modern models often use plastic, tempered glass or metal.

Some stair designs use artificial granite, ceramics, or even marble. The price of such products will be appropriate.

There are railings and bowstrings in a separate row. They are made from glued wood or various alloys.

In turn, the support post can be metal, wood or stone. The first two options are the most common.

Advice! In this case, the best option is to use a steel pipe. It has sufficient strength, and handrails can be easily attached to it.

Making a spiral staircase

Calculations

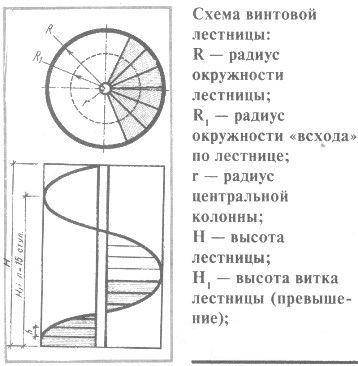

The manufacturing process begins with the calculation of all the necessary parameters. As an example, consider the case when we need to make a structure 85 cm wide and 2.7 m high with a central support having a diameter of 20 cm.

First, we determine the total diameter of our future product. It will be equal to the thickness of the ladder multiplied by two plus the diameter of the support. That is - 85 * 2 + 20 = 190 cm.

In this circle you need to inscribe the second circle. A man will climb along it.Its radius will be denoted as R1. It is calculated as the sum of half the width of the structure and half the radius of the B-pillar. In our case, it will look like this: 85: 2 + 20: 2 = 52.5 cm

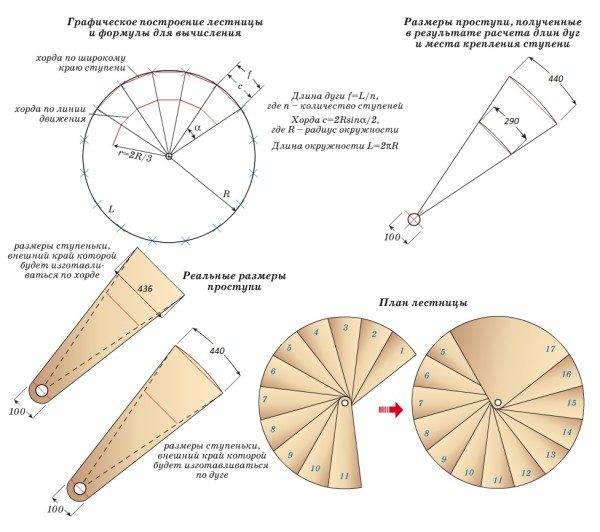

As for the width of the steps, it is no more than 40-44 centimeters. Homemade spiral staircases have one feature here. For them, this width will increase with distance from the center of the stairs. Therefore, for the calculations, we will use an average value of 20 cm.

Now let's determine the number of steps in one loop of the structure - we divide the length of the second circle by the width of the step. It looks like this: (2 * 3.14 * 52.5) / 20 = 16.4. We round this result and get 16 steps.

Next, we calculate the approximate height of the steps. For this purpose, we will divide the circle by radial lines into 16 equal parts.

At the same time, we note the following. In order for the ladder to be convenient during operation, the last step of the loop must be higher than the first one to the height of human growth. In addition, you need to take into account the thickness of the steps and add a small margin of 10-15 centimeters.

Taking the average height of a person to be 185 cm, the thickness of the step is 4 cm, plus a margin of 15 cm, we get the height of the coil equal to 204 cm.

We will divide this value by the number of steps: 204/16 = 12.75. Thus, we got the height of the steps, which will be 12.7 cm.

Our next step will be to calculate the total number of steps. The calculation instructions here are simple - we will divide the height of the entire staircase by the height of one step. It looks like this: 270 / 12.7 = 21.2. Round off and get 21 pieces.

Now we need to calculate the final step height. To do this, we divide the height of the structure by the number of elements obtained: 270/21 = 12.85. This means that this parameter will be equal to 12.8 cm.

Manufacturing of steps and railings

Steps should be made from solid wood such as oak or beech. And it is best to use ready-made rectangular elements. From them, you can cut out blanks of the desired configuration.

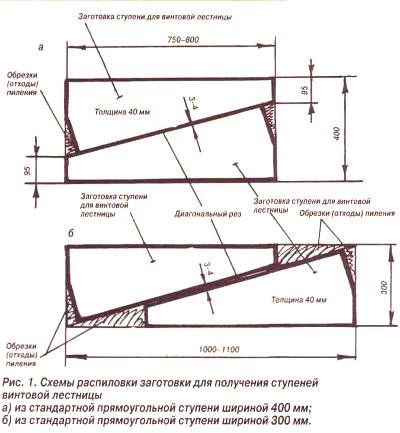

On sale you can find elements 4 cm thick with the following dimensions: 40x80 centimeters and 30x110 centimeters. Both those and others can be cut diagonally, resulting in trapezoidal blanks. After that, they need to give the desired shape and round off the edges.

We paint or varnish the finished steps. Then we attach special bushings to them. They will allow you to attach the steps to the support leg.

After that, we move on to solving the problem of how to make a railing for a spiral staircase. To create balusters, we will use metal or wooden rods. The handrails are made of laminated veneer lumber.

Railings can be made of straight bars or curved. The second option looks much more effective, but it is rather difficult to implement.

Assembling the stairs

How to make a metal frame for a staircase "width =" 640 "height =" 360 "frameborder =" 0 "allowfullscreen =" allowfullscreen ">

Having finished the preparation, we proceed to assembling the product with our own hands. In the course of it, it is imperative to pay attention to the reliability of the fastening of the central support. Indeed, first of all, the safety of all subsequent operation depends on this.

In the video presented in this article, you will find additional information on this topic (also learn how to make a metal frame for a staircase).