As soon as it comes to assembling a staircase for your own two-story house, the question immediately arises of how to make a staircase with your own hands, because at first glance it seems that there is nothing complicated about it.

Staircase construction on your own

However, a staircase is a fairly broad concept of construction, because there are quite a few types of stairs, materials and design features. To understand which type is suitable for an independent construction, you first need to designate the types and materials, and based on the analysis performed, make a choice.

Types of stairs

You can safely divide the staircase structures for a private two-story house into the main types:

- Marching. These are the most common designs that make it possible to make a march not only convenient and simple, but also functional.

- Spiral metal stairs. Quite complex structures that are not always ready to carry the full functional purpose, however, are ideal for small rooms where it is important to save usable space and gain access to the second floor.

- Spiral. This is something in between the first two types. Such a staircase is both functionally more diverse and purely aesthetically pleasing.

Material

In terms of materials, everything is even simpler, you can immediately identify the main and most spread of the proposal:

- Wood. Almost any staircase can be assembled from wood. Moreover, here are collected together and the positive qualities of the wood itself and the ease of working with wood.

- Metal. It can be cast iron, stunning spiral staircases, stainless steel, or just steel are poured from it. If the first option is unrealistic to do it yourself, then almost any person can handle stainless steel and steel.

- Reinforced concrete. Reinforced concrete staircases are not only the prerogative of high-rise buildings and apartment buildings. A huge plus of this design is the ability to give the stairs almost any shape.

Where to begin

From the choice of the type of construction and from the material. This is the basis from which to move further away. Using the example of how to correctly make a staircase with your own hands, you can consider a structure made of metal and wood, and in each of them give certain examples.

An independent calculation of all the necessary design parameters can be safely carried out with a marching type, otherwise it is best to rely on specialists, the screw version, for example, will require rather complex calculations. Therefore, the calculation will go on the example of a single-march rectilinear staircase.

A single-flight staircase consists of the following elements:

- Support beams. It can be stringers or bowstrings. The difference between them is in the way of fastening the step.

- Steps. They consist of a tread - a horizontal part, and a riser - a vertical part.

- Fencing. Not every structure has a railing, it already depends on the type of stairs.

Preparation

It is at the stage of preparation that calculations are made. Step-by-step work on the calculations, and accordingly on the complete preparation for the installation of the entire structure, can be done from scratch.

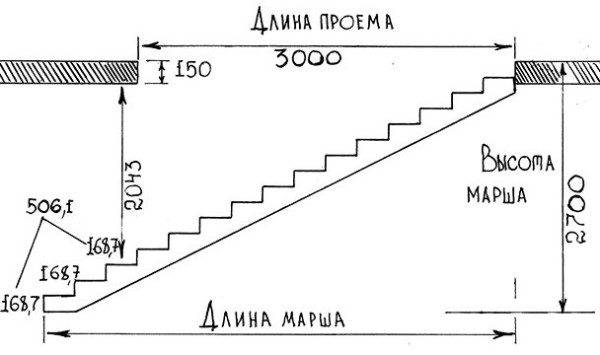

The height of the step is considered first. This can be shown schematically using the following example:

- The height is measured from the floor of the first floor to the floor of the second, taking into account the thickness of the interfloor overlap. Let's say it's 250 cm

- Medium riser height is used. On average, this is 16 cm.

Next, the number of steps is calculated using the formula: a / b = x, or a -250, divided by b-16 and it turns out x - 15.62... The value is rounded up, and it turns out 16 steps.

It is important if the question of how to make a ladder ladder with your own hands, for example, then this formula is also suitable, only with other parameters. In general, this is a universal calculation, and a formula. And yet, it is necessary to make the height of the steps the same throughout the flight of stairs, for this, the measurement height of 250 cm is divided, by the number of steps by 16 and the total is 15.62, as it was.

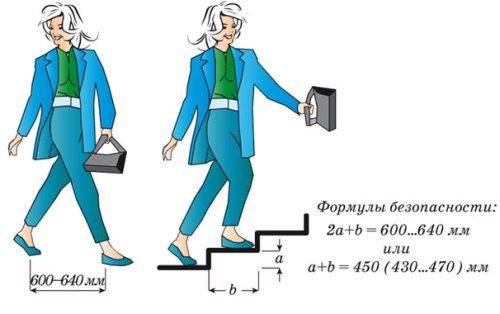

The tread width can be calculated using the formula 2a + b = 64 cm, where 64 cm is the average step of a person. However, specifically regarding the width, there are several examples of parameters that are simply selected based on the maximum foot size of the owner of a house with a staircase. So you can stop at 30 cm wide, that will be enough.

Moreover, such a width is a universal parameter that can be used in any type of stairs and with any material.

Regarding the width of the march, it can be noted that this parameter is strictly regulated in multi-storey construction, and in a private house, the owner is free to choose the size on his own.

The only thing worth noting is that before making a staircase in the house with your own hands, you need to decide on its functional "filling". That is, if it is to serve only for access to the second floor of a person, it may be from 0.7 meters width, and if it is supposed to raise furniture, or large household appliances, then you can increase the width to 1.2-1.5 meters.

Important! With an increase in the width, as well as the length of the span, there will be a need for an additional support beam.

At the end, the length of the staircase is considered, according to the formula - the width of the tread by the number of steps, in the case of the example, this is 30 * 16 = 480 cm.

Important! It is always necessary to calculate the height of the lumen so that it is convenient to climb it at full height. This height corresponds to a distance of 195-200 cm between the lowest step and the ceiling.

And the last thing to count the length of the support beam, bowstring or stringer. To do this, you need to calculate everything according to the Pythagorean theorem, and it is best to do this in an online calculator.

Selection of materials, wood

When it comes to a wooden staircase, the main criterion is the condition of the wood. It must be dry. Is the variety important? In principle, this does not really matter, but it is worth noting that, for example, conifers are more difficult to paint, but deciduous ones perfectly interact with paints and varnishes.

As for the dimensions of the elements of the wooden structure, these are:

- Support beam, 40-50 mm wide and 200-300 mm high.

- Steps, 25-45 mm thick.

- Railing, 1.20 cm high.

Important! Regarding the handrail issue, the height of the guardrail is defined by certain standards that include data on the center of gravity of a person, and provide for the safest height that must protect a person from bending over the fence.

Selection of materials, iron

Here the instruction is fundamentally different from the wooden version. No, all sizes and counts remain unchanged, but the parameters of the elements are different, on average they are:

- The cross-section of the support beam is 70x70. It can be an I-beam or a channel.

- Thickness of steps -2-4 mm.

But with the design of the fence, you can "play", use glass, plastic, stainless steel tubes, leather, wood, in general, there is a huge selection of materials.

Since the manufacture and installation of an iron ladder requires the use of welding, it is best to leave this moment to professional welders, and continue the conversation about how to make a wooden structure.

Assembling the stairs

After everything is prepared and cut to all sizes, you can proceed to the final assembly.

This can be shown schematically in the following sequence:

- Kosoura are installed.They adhere tightly to the floor surface and to the beam on the second floor. Fastening is carried out with steel anchors.

- Risers are installed. Fastening takes place on self-tapping screws.

- Steps are being installed. Fastening is also carried out on self-tapping screws.

Important! During installation, it is necessary to constantly check the planes with a building level. If the question is not how to make a rope ladder with your own hands, then the absence of a level will lead to slight distortions in the structure, and this will seriously reduce not only the aesthetic perception of the ladder, but also reduce the service life. Important! Every 4-6 steps, you can install an additional steel "tie" in the form of a steel pin, which will tighten the stringers or bowstrings. Subsequently, this will only add strength and rigidity to the staircase.

Conclusion

You can consider the option of how to make a handrail for a staircase with your own hands, but it will be either simple steel pipe structures, or simple wooden beams of a small section. It is more important to note the fact that the most correct choice is to buy ready-made balusters and railings, which are calmly installed on the stairs using special forks.

Output

With all the calculations, the choice of a simple design, and the elements prepared in size, it will not be a problem to assemble the staircase on your own. And the price of the issue will immediately decrease by at least 25%.

The main difficulty is precisely in the correct calculation, otherwise, in the video presented in this article you will find additional information on this topic.