Dreaming of a spacious, comfortable home, we often forget about such "little things" as a staircase to the second floor. And when it comes to construction, a sea of questions immediately arises about this: "what will the structure be?", "From what material?", "Who will make it?" etc. Therefore, in our article, we decided to analyze in detail this important point and together with you to make a staircase project.

Design of wooden ladders

One of the most popular materials for staircase structures is wood. Wood is "warm" and pliable, but it also needs to be handled very carefully.

Species such as ash, oak or beech require, for example, some processing methods, while larch, pine and birch must be handled in a completely different way. Therefore, each staircase project needs its own study and approach. We will consider the general rules for drawing up a plan for these structures.

Model selection

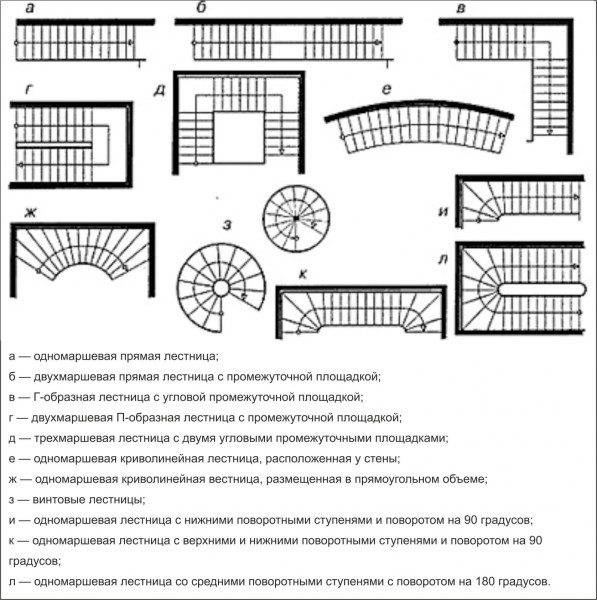

Today there are many interesting options for stairs:

- on kosoura;

- on the bolts;

- rotary with winder steps;

- screw - perhaps the most difficult to perform.

And the drawing up of a project of a spiral staircase is not within the power of every professional designer. Therefore, in our today's article on the topic "How to design a staircase with your own hands?" we will assume that you prefer the construction of a one-march model.

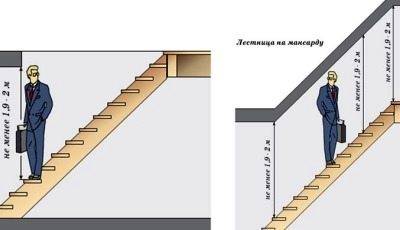

Caution - don't bump your head

First of all, as it were, try on your future ladder to the part of the house chosen for its location (by eye or on a drawing). Is it normally included in the area of the first floor, which is reserved for the beginning of the rise, as well as in the area and configuration of the opening in the interfloor overlap, through which the rise will end?

Single-flight design requires at least 1m² of floor space in front of itself and an opening above itself, approximately repeating its rectangular appearance, but reduced due to the part that can hang over the first steps.

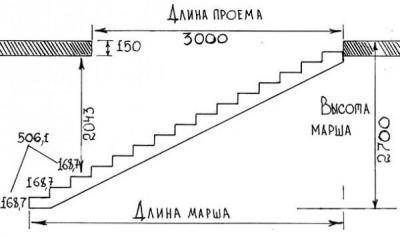

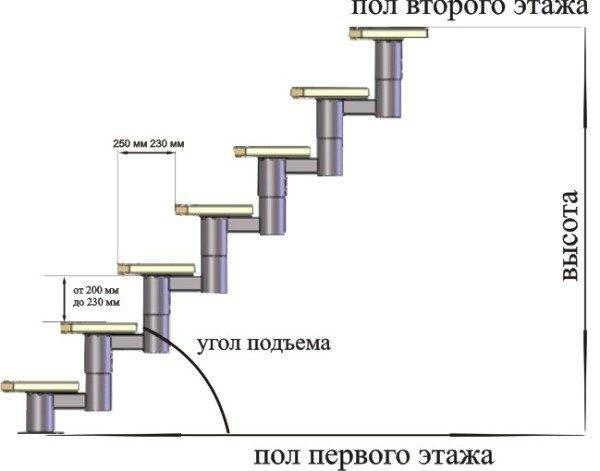

This nuance must be foreseen in advance in calculating the number and height of the steps, we will now produce them:

- We will conventionally take the ceiling height equal to 280 cm, plus the thickness of the interfloor overlap equal to 20 cm.Total - 300 cm (this should be our ladder). Let the steps in height be as comfortable as possible - 17 cm.To find their number, divide 300 by 17, we get 17.6 steps and round up to 18.

- Now it is necessary to divide the total height of the structure into the number of steps: 300/18 = 16.6 cm. Thus, we got the ideal height for each step of the future staircase.

- At the same time, do not forget to calculate the maximum permissible overhang of the interfloor over the initial steps: 280 cm to the ceiling, 190 cm height of the average person with a small margin. Then we count: 280-190 = 90 cm; 90 / 16.6 (one rung height) = 5.4 rungs. You can round up to 5 - this means that an overlap can still hang over the first five steps, and after that the opening should already begin.

Attention! But this is still not an accurate calculation of the opening. Where it exactly should start from, and what size it should be - read below.

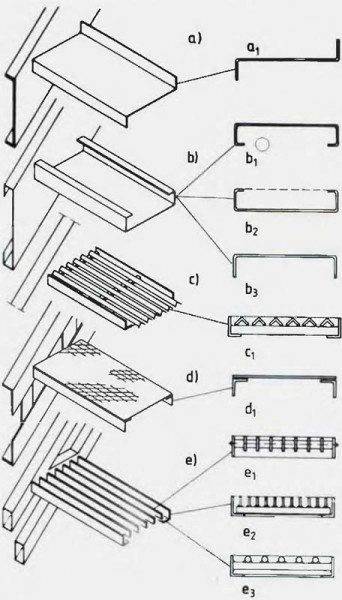

You can't hide your heels under the steps

Next, we have to find the width of the treads (steps). It should be such that the foot of an adult can fully fit on it (and when climbing, and especially when descending a ladder).

Of course, narrow treads can be compensated for by recessed or completely absent risers - then, when lifting, the front of the foot will fit into this space. However, the question remains unclear, how to go down? After all, you can't hide your heels in the openings under the steps!

Therefore, one way or another, but 30 cm step width should be required. Now we do this: 30 * 5 (steps) = 150 cm.That is, after 150 cm (meaning horizontally, along the floor of the lower floor) from the beginning of the rise and after 90 cm (vertically), the opening of the interfloor overlap will begin, the size of which will be 4.5x1.56 m.

Pythagorean theorem or ordinary rail

The total length of the stairs is usually calculated using the Pythagorean theorem. But, you must admit, this is not a very easy way, even for calculating on a calculator. It is not surprising and confusing.

Therefore, we will reveal to you a small, but very useful secret: you can simply use a long rail, placing it in the place of the future staircase. Then you just have to cut off an extra piece from it and voila - you have in your hands the exact length of both the structure as a whole, and each of its side bearing elements separately!

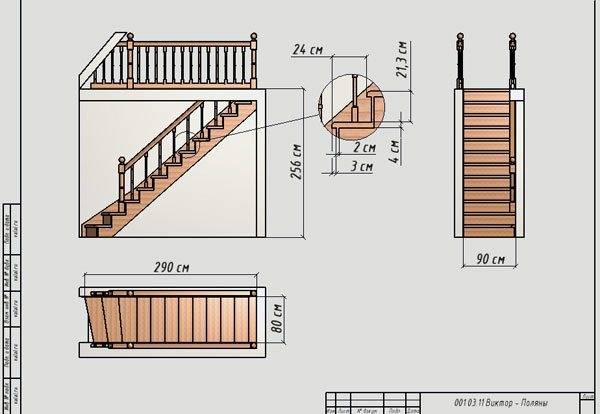

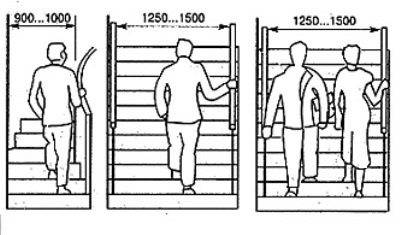

Optimal march width

The SNiP instruction states that the minimum comfortable width of the flight of stairs is 80 centimeters. But it is better, of course, if this parameter is 100-140 cm, otherwise, during the operation of the ladder, problems may arise with the transfer of furniture through it, as well as with the comfortable ascent of fat people along it.

Advice! Professional builders shared with us this trick: the width of the ladder should be a multiple of the width of the treads. If we take the data from the calculations made above, then these are 60, 90, 120 and 160 cm. Then all the details of the structure will look organic with each other.

This completes the design of the base of the staircase, excluding the railings! With all these dimensions on hand, you can proceed to the manufacture of parts and assembly. If for some reason you cannot create a plan on your own, then you can consider ready-made staircase projects and choose from them the one suitable for the configuration of your home.

Features of metal ladders

Not so long ago, these structures were used only in industrial premises and outside buildings, due to their operational properties - reliability, resistance to atmospheric, mechanical and chemical influences, fire safety, durability.

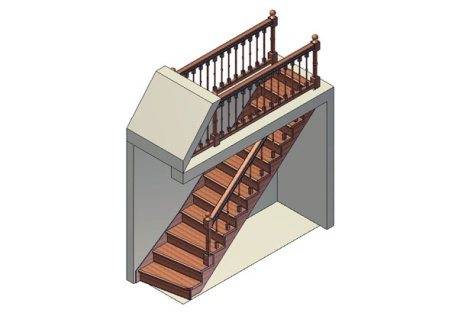

However, even today we can observe metal marches inside residential premises, and, it should be noted, their design sometimes surpasses the performance of wooden counterparts. Most often these are combined models - an ideal synthesis of durable metal with aesthetic wood.

In this case, projects of metal stairs involve the use of metal for the manufacture of load-bearing elements, and wood for steps, balusters and railings.

Note! The steel frame is much stronger and tougher than a wooden one, but at the same time the price for a combined staircase remains practically the same.

The most popular types of metal marches that you can do yourself are:

- Combined ladderswhere the stringers are made of metal (load-bearing elements on which the steps are fixed);

- Models on boltswithout frames. They usually consist of only one step, anchored to the wall with anchor bolts;

- Structures on bowstrings (inclined bearing beams), between which treads and risers are placed;

- Spiral staircases, with a supporting central pipe and steps located along it in the form of a spiral;

- Prefabricated modelsconsisting of parts already made at the factory.The process of their construction is somewhat reminiscent of the assembly of a children's designer.

Designing a single-flight straight ladder made of metal, in principle, is no different from designing a wooden structure. True, you will need to calculate how much metal profile, pipes, fittings and other materials you need to purchase.

Please note! It will be possible to independently make a high-quality metal ladder only after a series of practical exercises in working with metal and welding.

The metal frame of the ladder is constructed from a profile of various sections by cutting and welding. All seams and edges must be sanded, and the details are painted in any desired color. All kinds of pillars and stainless steel fittings, a cable system, tempered glass, crossbars, or forging can be used here as fences.

Output

The staircase to the second floor can be quite nondescript. On the other hand, if you make a little effort and put a piece of your soul into it, then it will become a bright accent in the interior of the whole house! Moreover, now you are able to independently calculate all the important design parameters - there should be no problems.

And in the video provided in this article, you will find additional information on this topic.

Great article !!!!!!!