Often, in private houses, it becomes necessary to erect a rotary L-shaped staircase, the angle of rotation must be performed at 90 degrees. In these types of structures, intermediate platforms are provided, however, most often they are replaced with winder steps in order to save space.

A win-win staircase is a complex structure, therefore, it requires accurate calculations of the main characteristics. Several basic techniques are used for this. Next, we will look at how to calculate stairs with 90-degree turning steps and make such a structure yourself.

main parameters

The calculation of the main parameters can be performed using:

- Mathematical formulas. This method will be difficult for a person unfamiliar with sopromat.

- Graphical methods This method is the simplest option, so we will consider it in more detail.

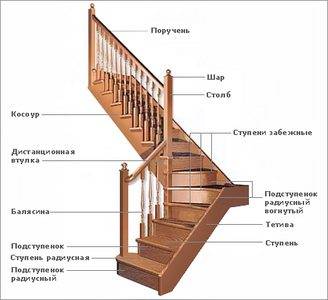

And so, in order to make the calculation of a rotary staircase at 90 degrees, you need to decide on a number of parameters. Among them, we will highlight the main ones: - The middle line of the march. On straight segments, this line runs in the middle of the march. On segments of a curved shape, it is drawn along a line parallel to the inner edge of the structure, at a distance equal to half the width of the step.

- The radius of the runner's center line curvature. This parameter depends on the radius of the circle that lies between the two stair flights.

- The angle of rotation is formed on the projection between the outer edges of the extreme steps in the horizontal plane of the flight of the stairs.

The width of the steps is considered along the centerline and is constant throughout the length of the flight of stairs. You can calculate a staircase with a turn of 90 degrees using the method of proportions or, in another way, proportional breakdown.

We need to know the following parameters:

- S is the width of the flight of stairs.

- I is the length of the projection in the horizontal plane of the staircase on the segment from the last step to the top of the turn-up angle.

- B is the width of the treads.

- R is the radius inside the structure.

For calculations, we need a graph paper sheet. It is necessary to draw a plan of the stairs in the projection, with which it will be possible to accurately determine the required dimensions, including the width of the step.

Advice!

If you have computer knowledge, then it will be easier to perform calculations using special paper programs.

First of all, you need to draw a middle line through the middle of the curved line from the top of the angle of rotation. Then you need to lay out the rotary steps in the drawing. In this case, you should pay attention to the fact that the width of the turning steps increases evenly.

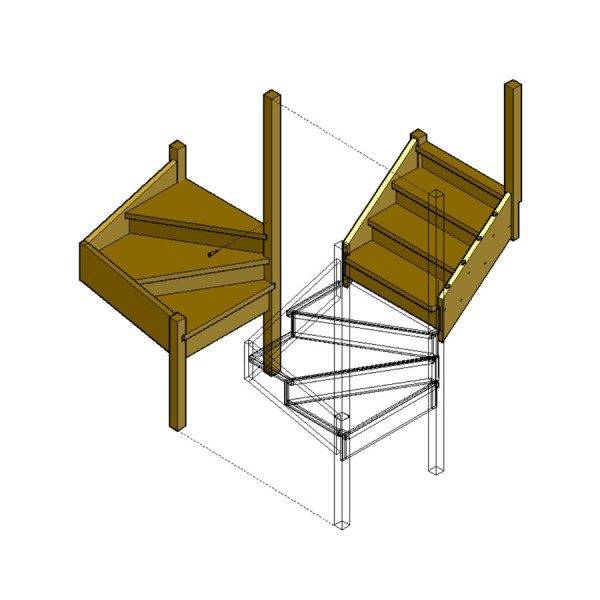

How to perform the layout is clearly shown in the diagram below.

Ladders with a 90 degree turn must be sized according to the following standards:

- The minimum width of the winder in a narrow place must be at least 120 mm.

- The difference in width between the narrowest and the widest step should not be more than 10 mm, and the calculation is based on this.

- The width of the flight of stairs must be at least 80 cm.

- The width of the winder on the center line must be at least 20 cm.

- The step height must be within 100 mm.

- The tilt angle should not exceed 23 - 37 degrees.

After the ladder with 90-degree rotary steps is calculated, you can start making it.

Making stairs

Materials (edit)

If a staircase with a turn of 90 will be performed with your own hands, then wood is the most optimal material for its manufacture.The fact is that turning steps, as practice shows, always need a certain adjustment and adjustment, no matter how carefully you perform the calculations. Only wood can allow making adjustments in this case, and it is possible to do this at any stage of production.

Many different blanks are offered in hardware stores. It is quite possible that there will be a ready-made 90-degree swivel staircase. However, this does not mean that during the installation process you will not have to adjust anything in size.

As a result, installing a finished staircase can be even more time consuming and troublesome than creating a structure from scratch. In addition, there is not always a guarantee that the finished 90-degree swivel ladder is made of quality material.

Therefore, having experience working with wood, it is better to make a ladder yourself, and only purchase parts of a complex shape in the store, for example, balusters.

For the manufacture of other elements, it is best to use wood of the following species:

- Oak;

- Beech;

- Ash.

It is also allowed:

- Pine;

- Larch;

- Maple.

The tree must be well dried to prevent deformation of parts, squeaks of steps, and, as a result, soon the structure will be repaired.

Of the materials you will need:

- Board with a width of at least 50 mm.

- Bars not less than 40 mm thick.

- Fastening metal corners, self-tapping screws, screws, assembly glue and screws.

Manufacturing of parts

The instructions for making a ladder are as follows:

- First of all, risers and steps are made of boards. On the turning steps, a corner is cut in the narrow part, in accordance with the data obtained in the drawing.

- For each step, two retaining beams must be made and four anchoring angles set aside.

- Then it is necessary to make a pattern, with the help of which marks are applied to the kosour or ladder bowstring.

- In the last turn, support posts are made, on which the stringers or bowstrings will rest. The diameter of the pillars must be at least 50 mm, and the height is determined at the design stage.

Advice!

To simplify the process of making winder steps, patterns should be made.

Ladder installation

The installation of the structure must be started with those elements to which later access will be difficult. It is recommended to first mount the upper part so that possible errors are concentrated at the first step.

The work is performed in the following sequence:

- The wall stringer is fixed to the wall with screws.

- Support pillars are installed. They can be reinforced with concreting or with anchor bolts.

- Outside kosour must be installed on the support posts and carefully leveled using a level and a square.

- The steps are connected to the bowstring using four metal corners and retaining bars. All fasteners must be glued. Please note that the steps are strictly horizontal.

- Next, the corner steps are mounted. They should fit snugly against the support. If the connection turns out to be not rigid, then it is necessary either to correct the step, or to make a new one.

- The next step is to install the risers.

- Balusters and railings are installed last.

- The work is completed by painting the stairs or opening it with varnish.

Advice!

For ease of installation, it is recommended to install the fixing points of the steps on the wall-mounted skimmer before installing it on the wall.

After all these steps, the 90 degree swing ladder is ready for use!

Advice!

It is very difficult to install the structure alone, so find assistants.

Finished ladder "Les-02"

Of course, all of the above work can only be done if you have some experience.Otherwise, it is better to purchase a finished product, despite the fact that the price for it will be significantly higher than for the stairs of our own production.

Preference should be given to proven manufacturers and models that are in demand. For example, the Les 02 right-handed staircase with a 90-degree turn has proven itself well in the market of ready-made, modular staircases.

The lift gate from the lower floor to the upper floor of this staircase is 2900 mm. The ascent angle is 44 degrees. The dimensions of "Les-02" in the plan are 2.145x1.365 m. For its installation, the size of the rectangular hole should be 2.2x0.87 m.

The maximum load per step is 350 kg. All structural details, except for the support column, are made of pine. If necessary, the staircase can be made higher, using supports, or lower, by removing unnecessary steps. Thus, it is easy to adjust it to a certain ceiling height.

The weight of the ladder with packaging is 140 kg. The product is delivered disassembled. Installation is carried out directly on site.

Output

You can calculate and make a corner staircase yourself if you follow the instructions above step by step. Self-fabrication of the structure gives a number of advantages over purchasing a finished product. In particular, such a staircase will meet all individual wishes.

However, if you are not confident in your abilities, then in order not to spoil the material, not to waste time and effort, it is better to install the finished product. You can get more information on this topic from the video in this article.