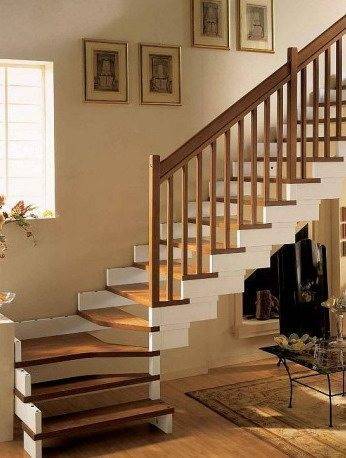

The dream of any owner of a private house with more than one floor is to have a beautiful staircase. Moreover, this design does not have to be ordered from commercial firms, where its price can be very high. The ladder can be made by yourself.

We will tell you how to do this in our article.

General staircase arrangement

It is a prefabricated structure - it consists of elements that are manufactured separately and then connected together. It is imperative to know them, as it will be necessary for the design.

Therefore, let's take a look at each of them:

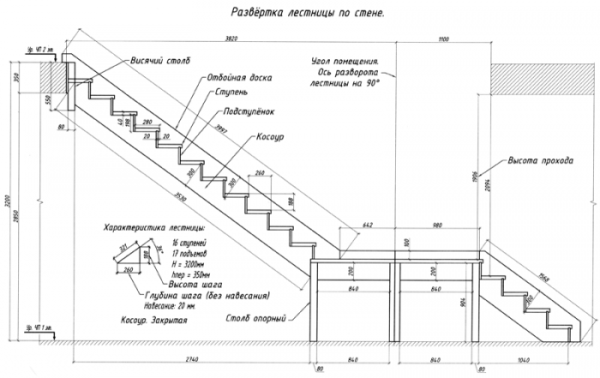

- steps - each of them consists of 2 parts: treads and risers. The first part is a horizontal work surface. Its width is usually 30 cm, and its length is from 90 to 150 cm. Moreover, this length determines the width of the entire staircase.

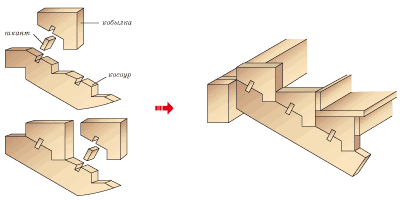

The second part of the step is vertical. Its length is from 15 to 20 cm. In some cases, for the overall beauty of the entire staircase, it is made without risers; - support beams - steps are attached to them. Beams are of the following types: kosour, bowstring, and also a post. For marching stairs, the first two types are used. The third is used for screw structures.

Kosour is the name given to a wooden beam with triangular cutouts for steps. In a ladder string, these cutouts are made only under the treads and exclusively on the inside of the beams; - railings - essential for safe stair climbing. They consist of a handrail and balusters. The handrails are on top, and the balusters support them, thus creating a natural fence.

There is also such a thing as a march. This term is called a certain set of steps and railings, which is set by the instructions for assembling the product. In simpler terms, these are parts of the structure, separated by staircases.

The process of creating a flight staircase

Most often, marching structures are used in private houses. And this is not surprising at all. After all, they are much easier to manufacture than screw ones. We will consider the process of creating this particular type of stairs, as the most popular and widespread.

Choice of materials

For the construction of staircase structures, coniferous wood is most often used. This is explained by the ease of processing and affordability.

More durable will be a staircase made of oak. But it will cost much more. In addition, oak processing is a very laborious undertaking. Working with this material will require not only significant physical effort, but also the presence of special skills.

Design

But, before starting practical work, you need to design. It should be borne in mind that any mistakes made at this stage will cause serious problems during assembly.

Therefore, all calculations made should be treated as carefully and responsibly as possible. We have to design all three types of building blocks of our future structure: steps, handrails and stringers.

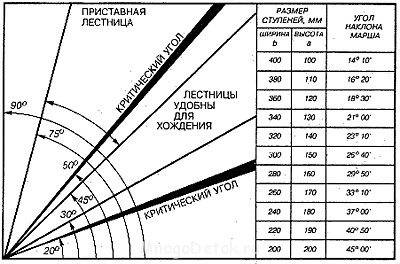

Let's start with the first item. We will calculate the steps according to the following formula:

2A + B = 64 cm. In this case, we take the width of this part as variable A, and its height as variable B. The second parameter, as a rule, is from 14 to 17 cm.

First, let's measure the estimated height of the entire staircase. After that, we divide it by parameter B. As a result, we get the number of steps that the staircase design will have.

For example, the total height of the product is 240 centimeters.The height of one step is usually 16 centimeters. We divide 240 by 16 and as a result we get 15. Exactly so many steps we have to make.

Now let's calculate the width - parameter A from our formula. Knowing the variable B, it will not be difficult to do this. There is another way to calculate the step width. For this purpose, you can use the table below. (see also the article Stair tread width norm, as well as other standards for its characteristics)

Advice!

Each step has a ledge.

This is the name of its part that hangs over the riser.

Its size should not exceed 3-4 centimeters.

Otherwise, it will be easy to stumble on such a step.

There is the following pattern. The higher the riser is, the narrower the step will be. But, nevertheless, its width should not be less than the height. The optimal value of this parameter is in the range of 290-300 m.

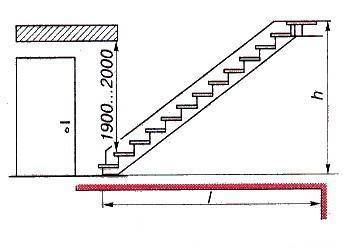

During design, do not forget about the distance from the steps to the ceiling or other objects located on top. It should be 190-200 cm.

Determine the horizontal dimension of the staircase. To do this, we will multiply the width of the steps by their number. In this case, we will take into account that the first step is the floor.

If the height of the structure turns out to be too high, you can make a staircase. The flights of stairs obtained with their own hands will have 7 or 8 steps.

If the project implies the presence of a strictly defined number of steps, you can make their height smaller. This will help accommodate the site.

Production of stringers

To create them, we will use pine boards with a thickness of 40 millimeters. They must be of good quality, free of knots and any damage.

This process goes as follows:

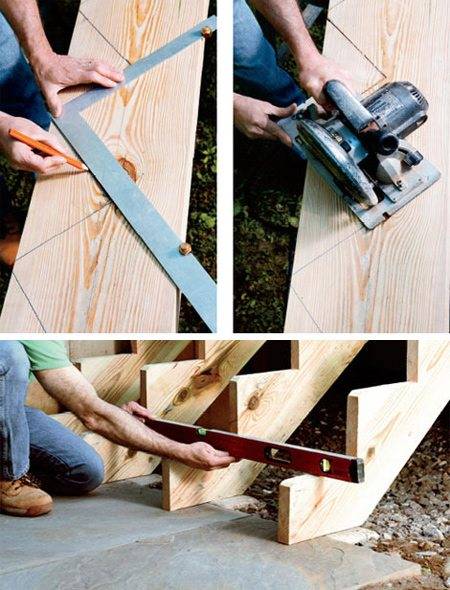

- first, we make a pattern that completely repeats the bends of the steps. With its help, we will apply markings to the blanks. Moreover, it is necessary to apply the lines so that the resulting teeth do not have an acute angle;

- after that, using an electric jigsaw or a hacksaw, we proceed to sawing out the teeth. The resulting blank can be used as a template for the rest of the stringers.

In total, 3-4 of them should be made. This amount will be quite enough to ensure the reliability and safety of our design.

Installation of steps and railings

The next stage in how to make a flight of stairs with your own hands is the installation of steps and railings. The steps can be attached to the kosoura using special wooden elements - filly, or directly. But before proceeding with their installation, you should prepare the required number of treads and risers.

In the preparation process, we also take into account the presence and size of the protrusions. We fix the manufactured elements with nails or self-tapping screws.

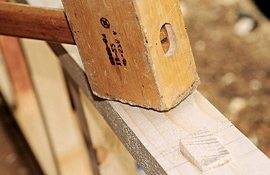

A more reliable type of fastening is the connection of parts using triangular-shaped fillies. They are fixed with dowels, having prepared grooves for them.

The connection will be stronger if the filly has a complex shape. For such elements, special grooves are made on the surface of the stringers. Connect the parts with glue and self-tapping screws.

Having finished the installation of the steps, we proceed to the installation of the balusters of the handrail. Then we proceed to fastening the handrails.

After completing the installation work, we begin the staining process. Painting is necessary to protect the wood surface from all sorts of destructive factors. This can be dampness, mold, or harmful insects.

Output

There are two main types of stairs - marching and spiral. The first of them are the most common due to the simplicity of their manufacture. The do-it-yourself marching staircase will serve you faithfully for many years if you take a responsible approach to the process of its creation.

It starts with design. At this stage, it is very important to correctly calculate all the dimensions and take into account all the nuances of the placement and subsequent operation of the product.

Having finished the calculations, you can proceed to the practical part of the work. In this case, first of all, it is necessary to select high-quality wood that does not have defects. The subsequent process of manufacturing and assembling parts is simple and accessible to any home craftsman.

You can find out more details about the manufacture of marching stairs from the video posted on our website. In the video presented in this article, you will find additional information on this topic.