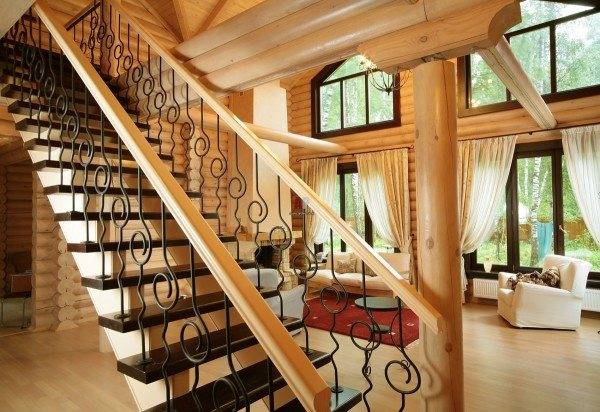

Stairs with wrought iron elements have long been widely used in the interiors of houses. They emphasize its style and individuality as, for example, wrought-iron staircases to the second floor can give any room an atmosphere of comfort, reliability and grace.

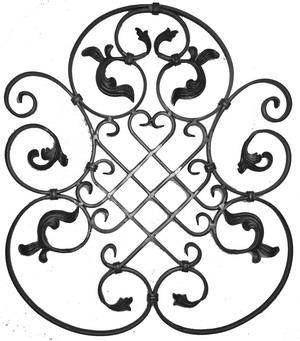

Fancy openwork patterns surprisingly attract the eye and make you look for a long time at all kinds of weaving of refined vines.

Therefore, forging is considered the most beautiful, graceful and unusually effective material for the manufacture of stairs - forged stairs. In the old days, forging products were available only to crowned heads or heirs to the royal throne. Fortunately, nowadays everyone can create a wrought-iron staircase.

Assembling a beautiful forged structure is a relatively straightforward procedure, although it is not easy to believe. Next, we will consider what types of forged stairs exist and how you can make them yourself.

Features of forged structures

For hundreds of years, forged stairs have been manufactured using the same technology, practically unchanged. Blacksmiths have passed on their skills from generation to generation, however, it has not yet been automated. Therefore, to create a truly openwork lace, a coarse anvil, a sledgehammer and pliers are used.

Since iron is a fairly plastic material, almost any image can be made from it. On the one hand, the impossibility of automating this process is even for the better, because handmade products are more valuable and look more interesting. For example, a unique spiral forged staircase will surely amaze your guests with its sophistication and airiness, as it is a real skill.

Another feature of forging is that it is a versatile product..

You can make a staircase for a house in any style:

- East;

- Classic;

- Gothic;

- Empire style;

- Art Nouveau style;

- Vanguard;

- Baroque

- Rococo, etc.

At the same time, forged railings for stairs have a number of advantages:

- Visual lightness;

- Transparency,

- Durability;

- Openwork;

- High degree of security.

Types of forged stairs

There are several types of wrought iron staircase designs.

Their choice depends on several factors:

- Convenience of movement;

- Financial opportunities;

- Spatial possibilities.

And so, forged metal stairs, according to their purpose, are divided into the following types:

- Basic;

- Auxiliary;

- Ceremonial;

- Input.

In addition, forged staircase structures can be:

- Marching;

- Screw;

- Self-supporting;

- Curvilinear.

Marching

The most traditional and demanded option is marching stairs. They provide convenient and safe movement, in addition, the marching structures are the easiest to manufacture. They are usually used in residential, industrial and public buildings.

Each march of such a staircase should contain no more than fifteen steps so that the ascent is safe and does not take a lot of energy. If the march turns out to be too long, then it is divided into two parts, between which I set the site. Such stairs are straight and rotary.

If the turn is made at an angle of 90 degrees, then the structure is called L-shaped. If the turn is made at an angle of 180 degrees, then the staircase is called U-shaped.L-shaped structures are suitable for most rooms, so they can be found quite often.

Also, U-shaped products look great as a central element in the design of the room. To save space, rotary stairs are made with winder steps. However, the ease of movement suffers.

I must say that the only drawback of such structures is their rather large dimensions, so they are not very suitable for small rooms.

Screw

Spiral staircases take up less space and look very nice, but less comfortable to climb, as they consist entirely of turning steps. Space saving is achieved due to the spiral march device.

Forged spiral staircases for the home are usually used as additional or decorative elements. They are very popular when planning country houses in a limited space.

Curvilinear

Curved structures are the most difficult to manufacture. As a rule, only highly qualified masters can do them. They have a semicircular shape and include run-in steps with an upper platform. Their advantages include a beautiful appearance and compactness.

Making a forged staircase

It should be said right away that during the construction of a staircase, forging is used only for support posts, railings and parts close to these elements. The very same staircase structure is the most common, so we will not consider its manufacture. It can be wooden, metal or combined, when the supporting elements are made of metal, and the steps are made of wood.

Advice! Products with wooden load-bearing elements, granite or marble steps and wrought-iron fences look great.

In addition, you can combine natural stone with steel, wood with glass.

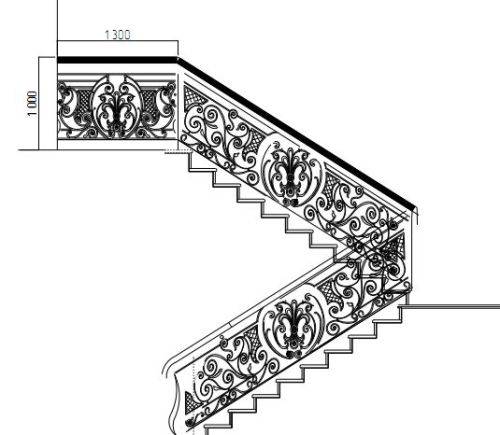

Design

The manufacture of any staircase structure begins with the design. At the initial stage, you need to come up with its appearance. Perhaps you will like some existing design of forged stairs, which you can make adjustments to your liking.

You can also create different sketches of forged stairs, from which you can then choose the most successful ones or combine them into one. In any case, the project must be created on paper so that you can select suitable forged elements from which the pattern will be created.

Advice! If you will be doing forging yourself, then the pattern should match your skills. Complex elements may require hot forging, which is quite difficult to do at home.

Material selection

If you decide to do forging yourself, then after completing the design, you should calculate the amount of material. For railings, it is better to choose a material that is easy to process.

Advice! For greater safety, you can use brackets made in the subject of artistic forging. They will add additional reliability and beauty to the product.

As a material, you can use metal profiles and rolled metal products with different sections. It is best to purchase metal with a small cross-section, so that it is easier to handle and deform.

Instrument preparation

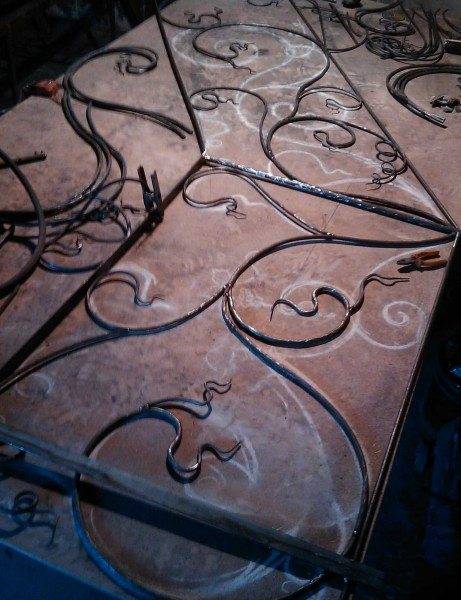

Before proceeding with the manufacture of the product, you must prepare the following tool:

- Welding machine;

- Mask;

- Electrodes;

- Prepared flat place for assembly, on which it will be possible to draw steps at a scale of 1: 1.

- Bulgarian;

- Two levels;

- Roulette;

- Protractor;

- Other little things that can come in handy during the creation process.

Transferring the drawing to the surface

The resulting structure in the sketch must be transferred to the surface you have prepared. First of all, you need to draw a frame for the future railings.The standard height of the fence should be 950 millimeters, but a gap of 100 millimeters from the step should be taken into account.

Your railing will probably have a wooden handrail about 30-40 millimeters thick. In this case, the frame must be made with a height of 820 millimeters.

Note! When creating handrails, it is necessary to adhere to high accuracy, since the spans of the structure have slopes. Changing the angle of inclination by just a few millimeters will lead to the need to rework the entire structure.

After the frame is drawn, the pattern of the future railing should be applied. It is better to do it with chalk so that it is easy to wash and reapply. After the drawing is ready, you can measure the length of each element.

Manufacturing of a structure

After all the dimensions are known, you can start creating the structure.

The manufacturing instruction is as follows:

- The material should be cut according to the size. To do this, you need a grinder, tape measure and glasses.

- Try to give each piece the desired shape. This process is quite complex and time-consuming. At first, it may not work, but you should continue to bend the workpieces and try to give them the most correct shape with a hammer. Of course, using a forge, this is much easier to do, but at home you have to deform the cold metal.

- When you finish bending the workpieces, you need to match them with each other and make sure that their shape is identical.

- Then, using a welding machine, you need to make a frame.

- When the frame is ready, you can start filling it in. (If you create a railing from ready-made forged elements, then all of the above points should be skipped and start with filling or making a frame).

- All elements should be assembled with patterns, according to the figure. At each point of contact between the parts, small spot seams must be applied so that, if necessary, the parts can be separated and redone.

- After all the work has been done, the entire section must be turned over and boiled on the other side.

- Then the section must be carefully installed on the previously prepared pillars and at the same time make sure that they do not deviate from the verticals.

We can assume that the staircase with forged balusters or elements of artistic forging is ready. True, the work does not end there. It is also necessary to give the product a complete look by completing the finishing for this.

Railing finish

In order for the forged staircase to the second floor to be really comfortable, all its elements must be smooth, otherwise they will cling to clothes when moving. To do this, you need to clean the assembly points with a metal brush or grinder with grinding wheels.

Advice! White primer must be applied to the railings before painting. This will make the paintwork smoother and more even. In addition, the primer will protect the metal from moisture.

When the seams are finished, the railings should be painted. This process should be taken seriously. For example, platinum can be applied to make the fence even more beautiful. To give the forging an antique look, it can be gilded.

Note! Forged railings made of bronze, brass or stainless steel are perfectly combined with modern materials. True, the price of such a ladder will be higher.

When finishing, you can use a variety of decor. In particular, together with forging I sometimes use ceramics, wood, glass, crystal and even precious stones. Thus, wrought iron railings will bring style and comfort to the house.

Output

Do-it-yourself wrought-iron stairs in a house are not such an impossible task. Of course, the product requires a little hard work, attention and desire, but it is quite possible to make it.

For more information on this topic, see the video in this article.