At all times, the owners of multi-storey housing construction have tried to turn staircase structures from banal means of transportation to another level into decoration of the interior of the premises.

In large houses, where there is enough space for a flight of imagination, with the current wide supply of all kinds of materials on the construction market, it is not difficult to build a truly architectural masterpiece. And it is not at all necessary that all this will be done by professionals.

We build ourselves - we need to save efficiently

With a strong desire and the presence of initial building skills, you can easily arrange a staircase with your own hands. But, you see, not everyone was lucky with a modern cottage with an area of 100 m2 or more. And everyone wants to create comfort and coziness.

So, if you have too little space for a full-fledged staircase with classic intermarch sites, do not be discouraged, this problem is solvable. In such cramped circumstances, the construction of a staircase with run-in steps is suitable.

What it is?

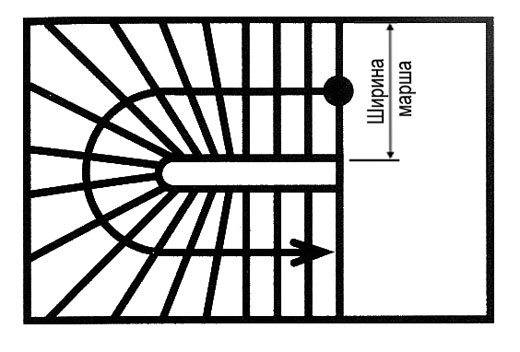

To reduce the area occupied by a staircase in a similar design, these very platforms are replaced with run-in steps, made with a narrowing to the center of the turning radius and widening at the other end.

In a similar way, the most diverse staircases are erected:

- Swivel 90 degrees with winder steps.

- At the foot.

- In the center.

- Curvilinear.

As you already understood, such staircase designs are not entirely convenient. For greater comfort when moving along it, it is advisable, if possible, to arrange a rounded fence.

This technique will also make it possible to make the run-in steps not so large and, accordingly, save on this. Although it is hardly worth starting to talk about savings when it comes to staircase construction.

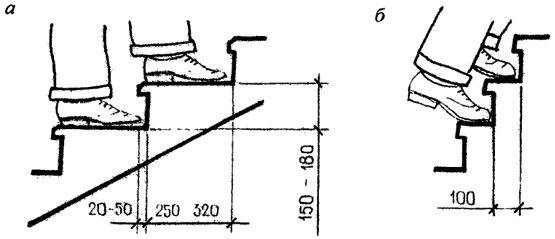

Important! It is not recommended to narrow the smallest part of the winder by less than 10 cm. On the other hand, no one needs huge "burdocks" either.

It is worth noting that a device of this design is not easy, but doable. If you are not confident in your abilities, get a ready-made staircase constructor with run-in steps, it costs a little more, but is easier to use.

Such products are always accompanied by instructions, usually quite detailed with assembly diagrams and a list of tools necessary for work.

Design It Yourself - Step-by-Step Process

When buying finished products, you should understand that:

- Such a design will still have to be customized in place, taking into account the specific dimensions of your room. And customizing and remodeling, as everyone knows, is more difficult than initially doing everything yourself.

- Unscrupulous manufacturers of stairs can use poor quality raw materials, which will quickly become unusable over time.

- The price of the finished structure is always much higher.

This article is for those who want to do everything on their own, to understand all the details and intricacies of creating a project plan. Let's start with a simple design - a staircase with winding steps at the foot and a 90-degree turn.

Tools and materials for work

In order for us to get a high-quality design the first time, it is necessary to purchase everything that we list below:

- Staircase details.

- Kosoura.

- Bowstrings.

- Steps: ordinary, run-in, podium.

- Riders.

- Details of the fence.

- Pillars.

- Balusters.

- Handrails.

For your information! A podium step is required (it is better to purchase two or three of these) in order to make it safe and comfortable to climb the runway section.

In addition to basic materials, you will need:

- Drill.

- Jigsaw.

- Hammer.

- Screwdriver.

- Roulette.

- Building level.

- A set of fasteners (self-tapping screws, Euro screws, etc.).

Assembly process

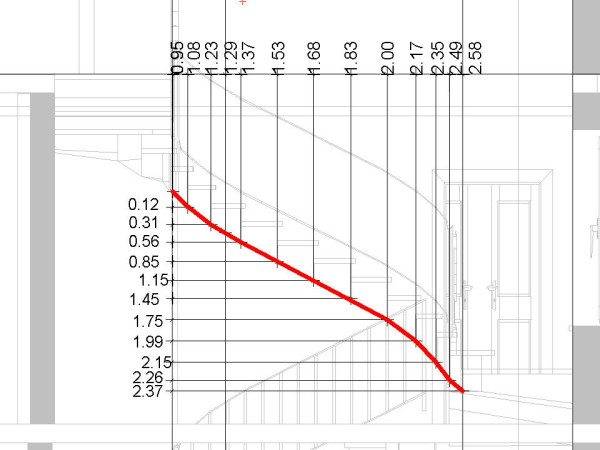

When calculating a staircase with winder steps, the drawings are an excellent aid. Visual images will not allow you to make possible mistakes (see also the article Calculation of a staircase with winders - how to do it right).

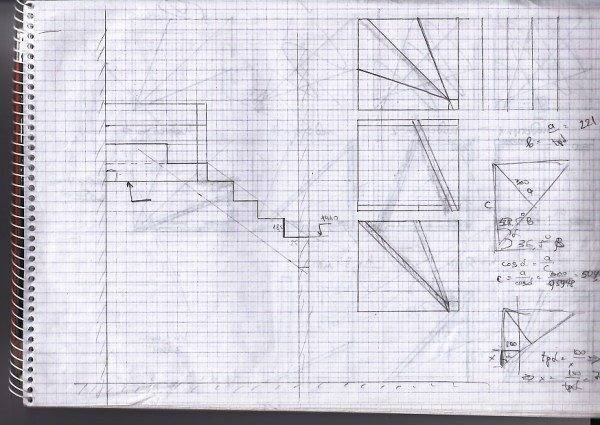

We start designing a staircase with winders:

- We draw a circle with a diameter equal to the width of the step (optimally at least 90 cm).

- We draw the middle line of marches in a circle through the center at an angle of 45 degrees.

- We divide the circle into segments equal to the depth of the steps of the ordinary steps (25-40 cm).

- Now we will draw straight sections of flights of stairs along the middle line.

- At a distance approximately equal to the width of the step, draw the lines AC and AB along the inner boundaries of the steps. From them we will calculate the winders.

- Place the AC and AB lines so that the inside of the winders is at least 10 cm, and the outside is about 40 cm.

- In the process of drawing for cutting steps, the dimensions along the edges of the surfaces can be slightly changed, but the depth of the step in the center should remain unchanged.

Attention! The transition from march to march along the run-in should be smooth. A staircase that is too winding is not safe and not very comfortable for the movement of the inhabitants of the house.

The height of the riser also plays an important role. Climbing steps that are too high is tiring, and a small, frequent step on low ones is even dangerous (you can get confused and stumble). Consider the interests of all residents, but try to get into the comfort range of 12 to 22 cm.

Now pick up your tool and start cutting, trimming and sawing all the materials you need to ultimately get an enviable result.

Using the same technology, you can calculate the design of a U-shaped staircase with a 180-degree turn. Such designs also have options for solutions.

They are made by:

- Two-flight staircases with a radial run-in part.

- Three-march with a short intermediate, between two sections of winder steps.

Wood - the ability to create on your own

Wood is still the ideal material for making a staircase in a residential building (also learn how to make run-in steps for wooden stairs). Wood structures have a number of advantages over their metal and concrete counterparts.

They:

- Warm.

- Textured.

- Eco-friendly.

- They are organic in almost any interior style.

- Long lasting.

- If necessary, they are easily repaired with the replacement of individual fragments.

The only drawback of wooden stairs is the high cost, with which only forged structures compete. The cheapest option would be, perhaps, maple, available in any quantity at almost every sawmill.

For the steps, a monolithic pine furniture board 900 * 1800 * 35 mm is suitable. You can purchase ready-made steps or order according to your individual calculations, but it will be twice as expensive. Here, in fact, is a brief summary of how to make run-in steps for a staircase.

Note! In addition to tools and materials, arm yourself with patience, yet the process of making and installing a ladder is rather complicated and lengthy. But the pleasure of the result will more than cover all the effort, time and money spent.

Output

In this process, as in any other, it is very important to pay special attention to the fasteners. Only reliable fasteners designed for increased loads are able to withstand the stress arising on the steps.

Indeed, it is often the horizontal plane that is loaded more strongly than the vertical supports. Therefore, run-down steps that do not have the correct shape must be installed with great care.

In the video presented in this article, you will find additional information on this topic.