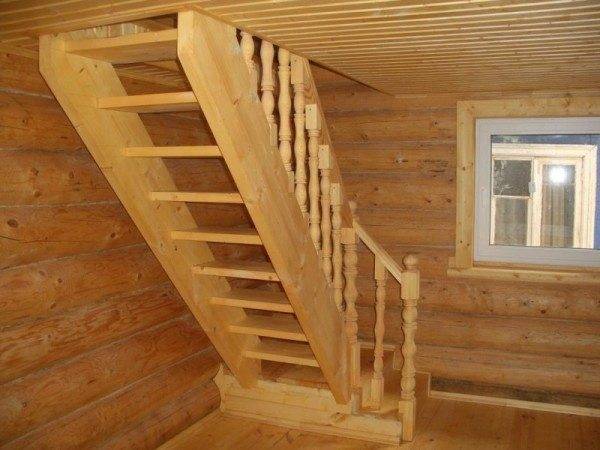

A staircase is an essential attribute of any building that has several floors. In a private house, a staircase usually becomes not only a means of combining floors, but also an important element of the interior, which can be ordered by you both from a construction company or made yourself.

In this article, we will look at the types of stairs for the house and the possibility of making them with our own hands.

Installation of stairs in a private house

The cost of installing a wooden staircase can vary from company to company within a fairly wide range. Naturally, the installation of an oak staircase will differ in price from the assembly of a similar structure, but made of pine. Most often, only average amounts are placed in the price lists. Therefore, if you are interested in a specific price for the performance of work, then you should have a quote for the installation of each element separately.

The specialists of a particular company can calculate the cost of all work only on the spot, after conducting an analysis and setting themselves precise tasks.

In this case, the following works will be taken into account:

- Installation of starting pillars of certain sizes.

- Installation of pillars of columns.

- Installation of balusters of the selected type, which can be made of wood, metal or plastic.

- Installation of boards for sites.

- The angles, turns and ends (snails) of the structure are also taken into account.

Naturally, in addition to the work itself, material consumption, as well as design features, will be taken into account. In addition, you can also order renovation of an old staircase or its dismantling and subsequent installation of a new structure.

Very often, such services result in a pretty penny, because many home craftsmen decide to install the installation of a wooden staircase with their own hands. However, to do this, you must first decide on the type of stairs.

Staircase constructions for private houses

Today there is a wide variety of all kinds of design features - from simple to elite stairs, however, in private houses, two types of structures are most popular:

- Marching or "classic". They represent a flat surface set at an angle of 30-45 degrees with steps. Such designs can be straight or angled and are by far the most common. The ideal choice for rooms where there is enough space for such large structures.

It is very convenient to climb and descend along such stairs, as they correspond to the biomechanics of human movements.

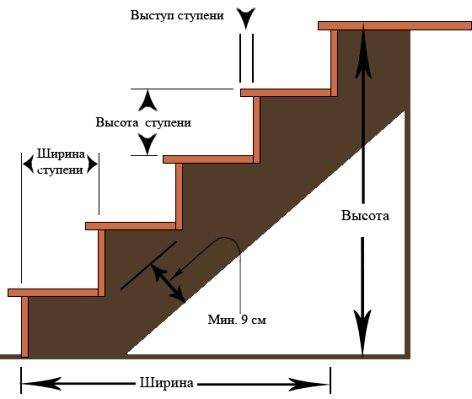

The size is calculated very simply:

- We measure the height of the wall and the length of the floor intended for the "shoe" of the stairs.

- We draw a right-angled triangle, the legs of which are the wall and the floor, and a surface with steps is used as the hypotenuse. The optimal angle is 45 degrees.

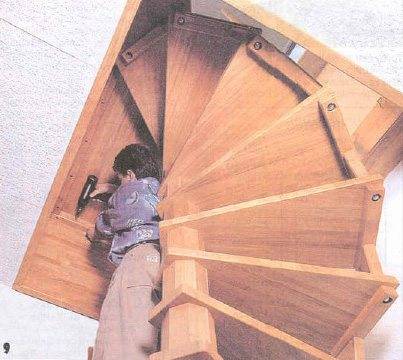

- Spiral or screw. The more complex and definitely more effective design of the spiral staircase cannot but attract with its originality. Most often, the entire load falls on one support, to which the steps are attached, interconnected by handrails. That is, it turns out that the ascent along such a ladder occurs around the axis.

Such designs are often used in areas with limited space.

Peculiarities:

- They can be located both at the load-bearing wall and in the middle of the room. Despite this, they are installed much less frequently than their marching counterparts, since they are less comfortable, which increases the risk of injury.

Advice! Remember: the smaller the opening reserved for the spiral structure, the steeper the staircase itself will be. This is a very important tip for those planning to install a second floor lift in narrow spaces.

- The main materials for the manufacture of supports, steps and railings are wood and metal.

Advice! For the convenience of moving along such a staircase, it is necessary to make the central width of the steps not less than 20 cm.The widest part is no more than 35-40 cm.

- For the most part, such structures are auxiliary and are installed in houses where there is already a flight staircase.

Preparing for installation

Before starting construction, you should check and assess the strength of the floor and floors. The slabs must be able to withstand the load 20% higher than planned.

Otherwise, the support structures may collapse. This can happen for several reasons:

- Large ladder weight.

- Incorrect design.

- Insufficient support points or load-bearing elements.

- Weak floor or low strength of the materials used in its manufacture.

Installing the ladder

Now let's look at how the manufacture and installation of wooden stairs is carried out. The instruction consists of several simple steps:

- We decide on the type of stairs and choose a place for it in the house. In the event that there is a lot of space, you can create a wide and comfortable staircase in the center of the house, which will add grandeur and sophistication to your home. If there is a lack of space, you should think about the wall option.

- We carry out the calculation of flights of stairs, as well as other elements, creating a project.

- According to the calculations, we purchase materials, or we entrust it to a specialized company.

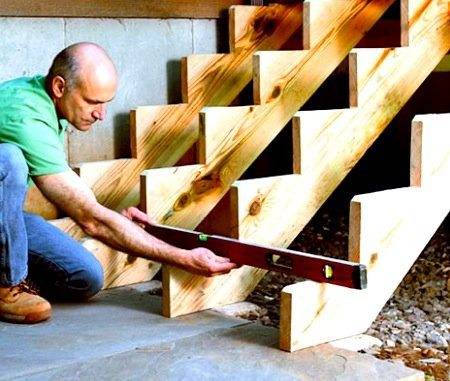

- We prepare beams (stringers and bowstrings), mark the steps and prepare for the installation of risers and steps.

- We collect marches. We attach the risers to them first, and then the steps.

- We install an intermediate platform between the marches, which is used as a boardboard (it can also be made of sawn timber).

- We install the flights by attaching them to the floor using a support crossbeam. We fasten the flights to the interfloor floor using anchors or bolts.

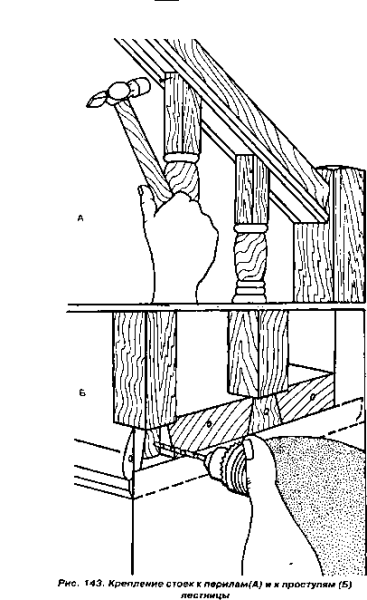

- We mount the fence. We install balusters, as well as intermediate posts, connecting them into a groove or using metal studs. We install the extreme pillars, attaching them with anchors to the main wall.

- We carry out the installation and fastening of the railings.

- If the design provides for the presence of decorative ornaments, cover them with an additional layer of varnish.

Wooden products are not only durable, but also have an excellent appearance, which will surely please the owners of classic-style houses. In the video presented in this article, you will find additional information on this topic (also learn about the features restoration of a wooden staircase).

Even if you are very scrupulously guided by this article - a high-quality, interior staircase will not work a priori. This is not only about technology, which is hopelessly outdated and contrary to today's rules for the manufacture of wooden stairs. All parts of the staircase are made of a spliced shield. The maximum will go to the dacha, and even then not for everyone. The ladder is manufactured and assembled on site, that is, "on the knee". The staircase is painted, apparently after assembly, which will entail such a creak, due to which the entire Internet is noisy. That they say "wooden stairs creak" And they creak thanks to such "woe to the masters." The staircase should be mounted using silicone sealant, which is impossible without painting, since the sealant will not have proper adhesion to the wood itself, but just right to the lacquer coating.

I have been manufacturing wooden stairs myself since 2002.

A cheap staircase with your own hands is certainly a good thing, but this is not a door that can be replaced later. I advise you to take a more responsible approach to the question of how comfortable your staircase will be, because it will stand for more than a dozen years.