A couple of decades ago, metal staircase structures were used exclusively in industrial and factory buildings, but modern trends have adapted them for indoor residential buildings. This is due to the high strength of the metal, moreover, it can be used to create any products: single- or multi-march, screw, etc.

To date, both home craftsmen and professionals have developed various drawings of metal stairs, each of which has its own design features. The most common of them will be discussed in this article.

About metal stairs

The fashion for metal came to city apartments and private houses with the advent of style "high tech"... This style promotes simple metal products in the interior with might and main. And this fashion could not ignore such an important structural element of a multi-storey building as a staircase.

Traditionally, stairs and fences were made of wood and stone, however, both materials have certain disadvantages before metal... Therefore, metal products quickly took a stable position in the modern market.

Advantages and disadvantages of metal stairs

When planning to install a stylish steel staircase in your home, you should first of all know about the advantages and disadvantages of this material.

Advantages

- The main advantage of such structures is that all of their prefabricated components can be prepared in advance.

- The key components are precisely matched to each other, which greatly simplifies and facilitates the do-it-yourself assembly process. Most DIYers will not need instructions to assemble such items.

- High strength and durability. Key components are able to withstand high loads, they are not subject to deformation and abrasion.

- Favorable price / quality ratio.

- Distinct sound when walking.

disadvantages

Advice! The problem with loud sound when moving up stairs can be solved by combining metal with wood, plastic or stone - materials that perfectly muffle the sounds of footsteps.

- Metal frame stairs subject to corrosion.

- Generally, metal steps are slippery.

- If you go into the aesthetics of design, then such products bring a cold atmosphere to the interior.

Types of metal structures

The most common types of stairs:

- Marching. It is the most popular because it is simple and convenient.

- Spiral metal staircase. More compact, but less convenient model.

And both types can be made of metal, you only need a correctly drawn up drawing of a metal staircase.

Frame options

There are two options for installing steps in the march:

- On braids, when the basis of the frame is sawtooth beams, on which treads and risers are laid.

- On bowstringswhen the load-bearing beams are straight with cutouts into which the treads are laid.

Among metal structures, the first type is much more common. We will consider them in more detail.

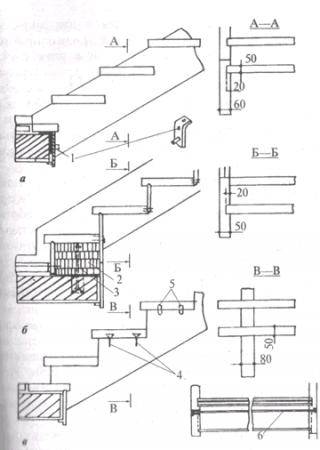

So, there are three types of frameworks:

- Closed.

It is the cheapest option and assumes that all elements will be hidden by treads and risers. In the simplest version, such a structure is made of channels and corners.

The closed frame of a metal staircase is most often a load-bearing base, which consists of from channelsthat are connected in pairs in several places. The corners are fixed on them, which serve as the basis for the installation of treads and risers.

Advice! Instead of corners, sheet metal can be used, which will greatly complicate the manufacture of the frame.

- Open, on two braids.

The material for such frames is a metal profile with a rectangular cross section. Both kosuors are made in the form of a "ladder", covered with enamel. This type of frame is called open because there are no risers, and the step consists only of treads.

This is the most common option because it is economical, while allowing you to create designs of original shapes.

- Open, on one braid. Such a frame is represented by a supporting beam, on which the platforms intended for the steps are strengthened. These stairs have an airy, as if weightless appearance.

Features of the steps

When designing steps made of metal, you must meet a number of requirements, including:

- Reliability.

- Convenience.

- Mandatory availability of special anti-slip protection.

- Harmonious appearance.

In this regard, there are several tips to help you design really high-quality, convenient and reliable elements:

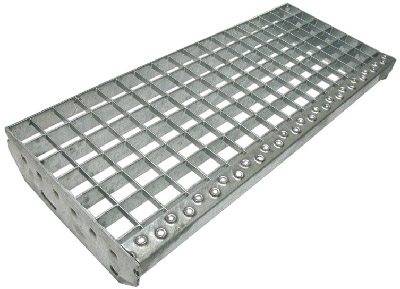

- The surface of the metal step should be either ribbed or covered with an anti-slip material (eg rubber). This is especially true for street models.

- The anti-skid effect can be achieved by using a lattice surface. Such options are used in the design of steps installed on stairs in technical rooms.

Conclusion

Such a staircase is a great option for a private home. If you correctly combine a metal frame with a wooden or plastic finish, you can "fit" such a structure into absolutely any interior. For your attention, the video in this article has prepared comprehensive information on this topic.