If you want to install a staircase in your home, you must first familiarize yourself with what the modern market offers. Not only did they begin to combine various materials, for example, metal and glass, wood and plastic, but also the frames of stairs began to be made of all kinds of shapes. We will talk about this separately in our article.

Types of frame structures

This section will describe the most popular and popular options for arranging stairs. This does not mean that the variety ends there, it is just better to consider those products that are easy to order and can be installed with your own hands.

Note! In fact, the easiest way is to install the frame of a wooden staircase, but, you see, natural material loses to metal in terms of reliability and strength. Even untreated iron is able to withstand loads several times higher than the bearing capacity of the prepared wood.

Closed frame

- The main feature of this type is its nondescript appearance, so it will be completely hidden under steps and panels, which will not allow you to unwittingly meet with raw metal.

- That is why, most often, such an iron frame of a staircase is made from cheaper channels and corners. Actually, this is the most popular option for self-erection, since only a minimum of a tool is required.

For your information! The main mistake of beginners is an oversight of the bearing capacity, which leads to deformation of the structure, in some cases, even to partial destruction. Therefore, it is necessary to entrust the design of the staircase frame to people who are at least versed in construction concepts.

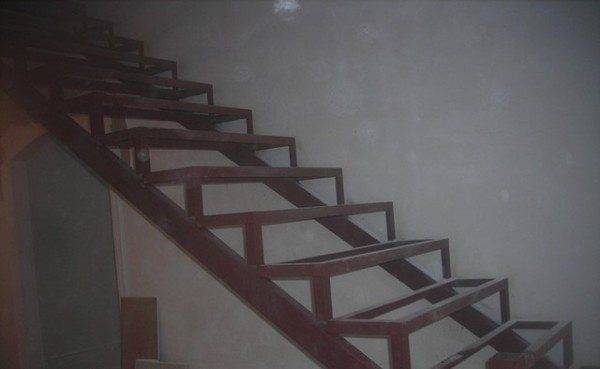

The closed frame looks quite simple:

- The struts are the channel, which is also the fastening bridges connecting the struts in several places.

- Metal corners are chosen as supports for the steps, it all depends on the thickness of this product, if it is insufficient, then, for example, a wooden step will lose significant strength.

Advice! To hide the iron frame for the stairs, you can use either wood paneling or drywall.

Open frame

Open bases can be divided into two types:

- With two stringers - externally, the supporting element is made in the form of a "ladder", with cutouts equal to the width of the steps. They are immediately covered with decorative means (enamel), which gives them a finished look. It is more difficult to make such a structure itself, you will have to work with sheet metal.

- With one stringer - the supporting element looks like the one described above, only it is installed alone in the center of the steps. At the same time, the staircase looks more light and transparent, but do not forget that if the width of the steps is large, then their deformation (deflection) is possible.

To avoid this, it is better to install additional supports on the side, interconnecting 2-3 steps. One stringer is the most optimal frame for a spiral staircase.

Note! The price varies greatly between straight and twisted supports, so calculate the costs before designing.

Making a frame from a channel

Now let's create our base for stairs on a metal frame, without assistance. For this we need:

- Channel. Although it can be replaced with a shaped tube, it is more rigid and reduces the generated vibration.

- Metal corners 40x40 mm or 20x40 mm.

- Welding machine.

- Hacksaw for metal or grinder.

- Drill.

Getting started:

- First of all, you need to cut the channel according to the size.

- Using welding, fix the channel in several frames, which will differ in height.

- Weld them together so that you get one whole march.

- If this is enough, then you can start attaching the corners, if you have two marches, then you need to repeat all the procedures and make another frame.

- Anchor the steel ladder frame to the floor and walls, if possible.

- Cut the metal corner to a size equal to the depth of the steps.

- Weld the corners to the channel so that one side of it remains accessible for fixing the steps.

- Using a drill, drill two holes in it for self-tapping screws (if the step is wooden).

Advice! After finishing work, take a file in your hands and process all seams after welding.

How to make a spiral staircase

You already know how a straight line is done ladder on a metal frameNow let's deal with the screw design.

To do this, you will need:

- A pipe of the required diameter and sufficient length.

- Another pipe, but with a larger diameter (by 2-3 mm without taking into account the thickness of the metal).

- Metal corner.

If all the materials are available, then you can get to work:

- First of all, the pipe of the largest diameter is cut into sleeves with a length of no more than 250 mm. This is the distance between the steps, if it seems to you that it is large, then you can cut 220 or 230 mm.

Important! Cutting should be done perpendicular to the pipe itself so that the plane is even, otherwise it is unlikely that it will be possible to install the steps exactly.

- Now you need to measure the distance for cutting the metal corner. This requires the temporary installation of a central support tube.

- Dimensions are taken for each step separately, since even differences in 3-4 mm.

- After measurements, we cut the corners according to the results.

- Using a welding machine, we weld triangular shapes (it is not necessary that the triangles will be the same).

- We weld the molds to the sleeves.

Advice! In order not to get confused, number the segments in the order in which they will be put on the support tube.

- We put the sleeves on the main pipe. If they dangle a lot, then they should be fixed with a drill and self-tapping screws.

- We install the support pipe in its place and fix it. To do this, it is better to weld small metal plates from both ends, through which anchor bolts will be drilled into the floor and ceiling.

Output

Frame stairs for a house should be erected during the construction phase, so you can not be afraid to damage the flooring or wallpaper on the walls. The easiest way to do this is if you need a staircase in a frame house, monolithic partitions will not interfere with you, there is always the opportunity to bypass a wall or partition.

On the other hand, erecting a stair base at the construction stage means determining its appearance, which is not always possible, because the design of the room may not yet be ready. In the video presented in this article, you will find additional information on this topic (see also what are the steps for concrete stairs).