Are there instructions for testing ladders and stepladders? When, who, and how should they be tested?

Let's find out.

Why is it needed

Indeed: what's the point in periodic checks? What happens to a piece of metal?

Alas, it's not that simple.

- Ladders are not only metal... Due to its dielectric properties, wood is also used in the manufacture of stairs (primarily for the needs of electricians). Decay and carpenter beetles can greatly affect its durability.

- There is such a thing as metal fatigue.... Minor deformations to which it undergoes during operation leads over time to the appearance of microcracks affecting the strength.

Useful: welded joints are the most vulnerable.

They are always less durable than solid metal structures; deformations affect, first of all, their reliability.

- Damage due to improper handling and rough mechanical influences also cannot be canceled.l. Not every user of the equipment will immediately notify the occupational safety engineer about its breakdown, especially if the breakdown was admitted due to his negligence.

Periodicity

- Inspection of fire escapes, in accordance with clause 41 of the Fire Safety Rules of the Russian Federation, should be carried out at least once a year; tests should be carried out at least once every five years. It is worth clarifying: fire escapes are not subjected to operational loads, are made only of steel and, with rare exceptions, are stationary structures without moving elements.

- The frequency of checking ladders and stepladders made of any metal is once every 12 months.

- Finally, the timing of inspection of ladders and ladders made of wood - once every 6 months.

In addition, ladders and stepladders for any purpose (except, of course, household) must be checked and tested:

- Before commissioning.

- After major repairs.

The last point probably needs some clarification. Steel and wooden stairs have to be painted periodically with the old paintwork stripped. These works are considered current repairs; but restoration of damaged welded seams or replacement of crossbars - capital ones.

Testing

It is worth separating the inspection and testing procedure. If the first operation is reduced to a visual assessment of the condition, then the second requires special equipment (albeit simple).

Visual check

What is being tested?

- Availability of an inventory number.

- The integrity of the product. All joints (including movable ones) must be visually in good condition: not have cracks, backlash and other defects. All-metal elements of the products are also checked for cracks.

- Stability. The stepladder should rest on the floor plane at four points at the same time. The ladder, standing on both bowstrings, must be in a strictly vertical position.

- No visible deformations. A buckled crossbar or a jammed bowstring on an aluminum ladder means that the product needs repair or replacement.

- No burrs, sharp edges or cutting edges. It seems that there is no need to explain the reasons.

- On steel products - the presence of an anti-corrosion coating.

Useful: the simplest anti-corrosion protection, which can be easily done with your own hands - painting with two layers of alkyd enamel.

The price of paint - within 200 rubles for a 3.5-kilogram can - will not be burdensome for the most modest budget.

Static load tests

Testing begins with the installation of an extension ladder or ladder on a solid base. At the same time, for testing the ladder, a support is required: it is installed at an angle of 75 degrees to the horizon. The three-knee ladder is fully retractable.

The test itself boils down to creating a static load on the rungs and ladder strings. There is a time limit: the duration of exposure to the load is two minutes.

How is each of the elements of each type of ladder tested?

- The test of a sliding ladder begins by applying a load of 200 kgf to the unreinforced rung of the lower knee. The point of application is the middle of a step or rung.

- The bowstrings of the sliding ladder are tested by applying a force of 100 kgf to each of them. Of course, every knee is tested.

- Then both bowstrings are loaded at the same time. An effort of 200 kgf is applied to the middle step of the middle link.

- The ladder is tested by applying a force of 120 kgf to any of the middle unreinforced steps. After a two-minute test, the product is carefully inspected: deformations and defects should not appear either on the step itself, or in the places where it is inserted into the string.

- The ladder is loaded with 120 kilograms with an attachment point in the middle of any unreinforced step in the middle of the ladder. If there are steps on both sides of the ladder, then the second side is tested in the same way; if the second knee serves only as a stop, its test is reduced to creating a load of 100 kgf on each bowstring in its middle.

Documenting

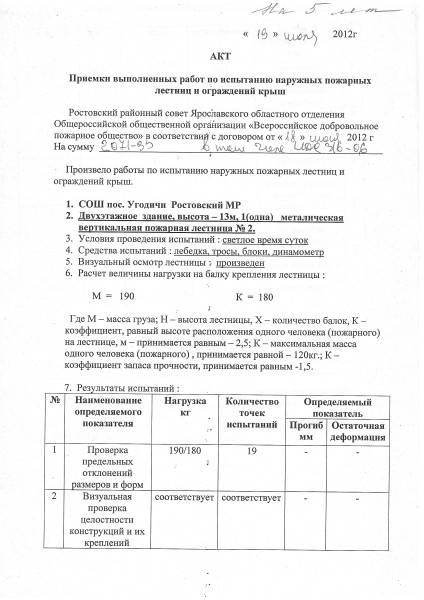

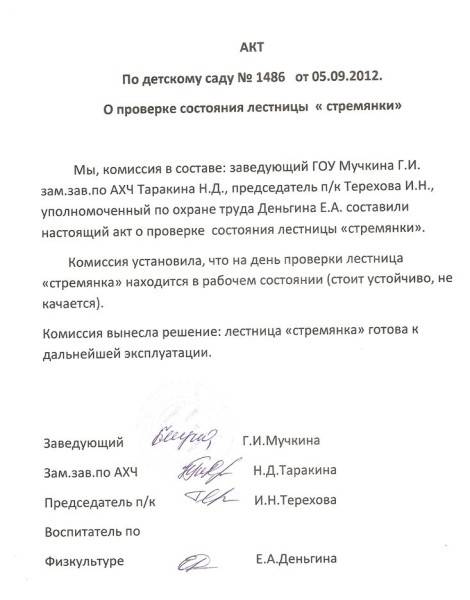

At the end of the work, an act of checking the stairs and ladders or an act of testing them is drawn up.

There are no strict requirements for its form; the following points are usually present:

- The composition of the commission, indicating the position held, surname and initials.

- Description of the work performed (visual inspection, the force applied during the test, and the point of its application).

- The presence or absence of inventory numbers.

- The presence or absence of claims about the stability of the tested products.

- List of identified defects in strength, deformation, burrs, damage to the anti-corrosion coating, etc.

- List of inventory numbers of products that have been tested and approved for further use.

- List of inventory numbers of stepladders and ladders to which claims have arisen, and recommendations for their repair or disposal.

In addition to the act, the results of inspections and tests are recorded in a register and accounting log maintained by an appointed official (most often - an occupational safety engineer).

The following information is entered into it:

- Record number.

- Date of the test.

- Description of the type of stairs (dimensions, material, presence of hooks, platforms, etc.)

- Inventory number of the item.

- Test result.

- Date of next test.

- Signature of the person in charge of the test.

Another requirement is a stamp on the date of the next tests on the ladder itself. It is placed with a permanent marker or paint on one of the bowstrings.

Requirements

As additional useful information, we present excerpts from intersectoral OSH rules.

We are interested in the requirements for ladders and stepladders related to the safety of work at height.

- Ladders are limited in length to 5 meters. If it is necessary to perform work at a higher height, work is organized from a fenced platform of a mobile tower or winch.

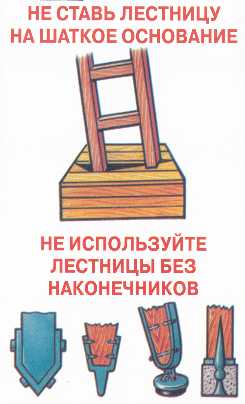

- Ladders and stepladders must be provided with devices for a secure stop, preventing them from shifting or falling. When working on the ground, the tips of the bowstrings are made pointed; if you plan to work on a parquet, screed or other flat solid surface, use rubber shoes.

Useful: in general, there are no strict requirements for the material of the shoes.

They can be made of any non-slip material.

- If you plan to work from a ladder with its emphasis on pipes or wires, the upper ends of the bowstrings are supplied with hooks or grips of any type. The simplest solution is a chain with a carabiner of sufficient strength.

- The height of the ladder should allow the worker to stand at least one meter from the top step. If the height of work is more than 1.3 meters, a safety belt is required. It attaches to any solid structure or to the ladder (if it is itself securely fixed). (see also the article How the width and height of a stair tread are determined)

- Wooden ladders can be spliced with metal clamps and tested as described above. In this case, no more than two ladders can be spliced.

- If the angle to the horizontal exceeds 75 degrees, additional fastening of the upper part of the bowstrings or one of the upper steps to the stationary structure is mandatory.

Output

There is a wise saying: safety rules are written in blood. Despite the pathos of the statement, we will take it seriously: sometimes it is too expensive to pay for inattention to trifles.

As usual, in the video presented in this article, you will find additional information on this topic. Good luck in job!

Good afternoon, tell me please, are metal ladders being tested to any height?