What is the test procedure for ladders and step ladders? What are the requirements for them? How often are tests and checks carried out?

Let's try to answer all these questions.

Goals

The main goal is one - safety. However, from the point of view of common sense, periodic tests of the ladder and stepladders the installer or electrician looks strange. It would seem, why arrange repeated events of the same type over and over again? Isn't it enough to check and test the inventory once - upon receipt?

Alas, not enough.

To understand the reasons, you need to get acquainted with the materials used and their operating conditions.

- External fire escapes are designed for emergency evacuation in the event of a fire and for access to the source of fire when the main ladders and passages are blocked by fire. In their manufacture, exclusively steel is used, the vulnerability of which is corrosion. Of course, it can have a noticeable effect on strength and load-bearing capacity.

- Testing of ladders and ladders made of aluminum, which are used in various works at height by bricklayers, plasterers, lighting fixtures, etc., is necessary to identify mechanical damage and cracks resulting from metal fatigue. Both movable joints and steps are subjected to significant loads and deformations during work; sooner or later this will lead to a dangerous drop in strength. And, of course, it is better to identify it before the breakage of the ladder leads to falls and injuries to workers.

- Dry wood is a dielectric. That is why electricians use wooden stairs. However, wood is vulnerable to decay and wood borers; testing of step-ladders, and in this case, is designed to proactively reveal a critical decrease in the strength of the structure.

Useful: impregnation with antiseptic and drying oil can significantly extend the period of trouble-free operation of a wooden staircase.

Timing

What is the frequency of testing ladders and stepladders?

The answer depends on the area of their application and the material used.

- The timing of inspections and tests of fire escapes is stipulated in the PPB RF (Fire Safety Rules). Paragraph 41 of the Rules requires an inspection at least once a year, and tests at least once every five years. In addition, tests can be ordered based on the results of the inspection in the event that the state of the fire escape seemed to the commission not trustworthy.

- Terms of testing industrial ladders and step-ladders made of metal - steel or aluminum - every 12 months.

- Periodicity of testing stairs and ladders made of wood - 6 months.

In addition to the indicated terms, tests are necessarily carried out:

- Before the start of operation... The equipment is tested immediately after purchase and, if not tested, is returned to the supplier.

- After any major overhaul... In this case, capital repairs mean all types of repairs, except for periodic painting and cleaning of corrosion traces.

Authorized persons

Who Tests Ladders and Stepladders?

There is some confusion in this issue in many enterprises. In most cases, the mission is entrusted to the occupational safety engineer or, in the absence of an appropriate full-time position (for example, in a kindergarten or school), to randomly appointed employees of the enterprise.

It's funny: in schools, the victims were usually a physical education teacher with access to sports equipment of a certain mass, and a labor worker, probably because he could find a way to fix the weights on a ladder.

Let's try to find the truth.

The search for at least some kind of legislative framework leads us to a couple of interesting documents:

- In the order of the Ministry of Energy No. 261 of June 30, 2003 it is written that mechanical tests of equipment are carried out before electrical "trained and certified workers." There is no further explanation in the text of the order.

- Intersectoral labor protection rules when working at an altitude of POTR M-012-2000 in paragraph 4.1.18 verbolut is completely tricky: the person responsible for the condition of ladders and stepladders is an engineer and technical worker appointed by the management of the enterprise; he also conducts (literally) "examination during the test." However, routine inspection before use is carried out by the workers themselves.

As always, some legislative vacuum stimulates market proposals in the relevant area. Instead of trying the stairs with your own hands, and in the event of any industrial accident, to have a great and bright feeling with representatives of the ministries, it is much easier to contact an organization accredited by Rosstandard.

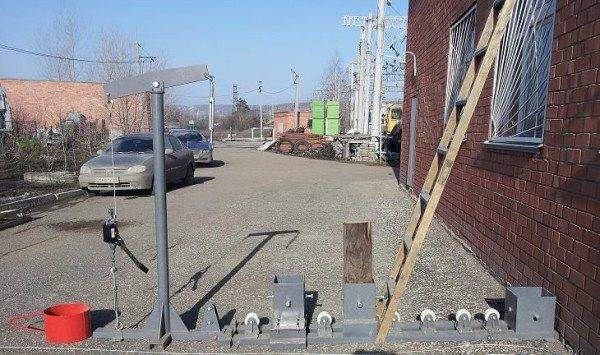

As a rule, instead of primitive weights on chains or ropes, she has at her disposal a full-fledged stand for testing ladders and stepladders; a certified test report with conclusions and recommendations solves all problems with safety claims at the enterprise.

However: the price of testing one step-ladder is quite normal for Moscow - about 500 rubles - with a large fleet of tested equipment, it can result in very significant sums.

How does this happen

What are the rules for testing ladders and stepladders?

To avoid confusion in terminology, let's distinguish between validation and testing. In the first case, the state of structures is assessed visually, in the second they are subjected to static loads. So what happens and how?

Visual assessment of the condition

The following is subject to verification:

- Inventory number - the very fact of its presence and compliance with the accounting journal.

- No visible damage. Joints - movable and fixed - must be visually intact, free from backlash, cracks and other defects. Solid elements are also checked for cracks.

- No deformation. The steps of the stairs should not be bent; the bowstrings of aluminum ladders must not be crumpled.

- Stability. The stepladder on a flat surface should stand on all four legs; a ladder standing on two bowstrings must stand upright, without a roll to the right or left.

- Splinters, chips, burrs, sharp edges and potentially traumatic protrusions should not be.

- Steel products are supplied with an anti-corrosion coating (in the simplest version - paint and varnish). Wooden ones should not have weakening bowstrings and steps of cracks; gluing or sealing of fractures with putty is not allowed.

Testing

Are there instructions for testing ladders and stepladders? Of course! The applied force, the direction of the load, and the position of the ladder are regulated.

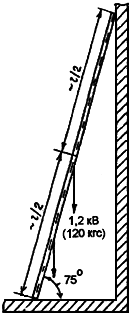

Before testing, ladders are installed against a wall or other support so that the angle between the ladder bowstrings and the horizon is 75 degrees. Three-knee ladders extend completely; the ladders are installed on a flat surface.

The duration of the static load in all cases is two minutes.

The procedure for testing ladders and stepladders is as follows:

- The step of the lower knee of the sliding ladder is loaded strictly in the middle with an effort of 200 kgf.

- Then each of the bowstrings of each knee is loaded in turn. The load is 100 kgf.

- The final stage of the test is a load of 200 kgf applied to the step in the middle of the middle knee. The goal is to load both bowstrings at the same time.

- The ladder is tested with a load of 120 kgf on one of the middle steps.

Important: in general, this is sufficient; however, if during visual inspection the condition of any other stages aroused suspicion, each of them is checked.

- The stepladder is tested with those 120 kilograms on the middle step. The second knee of the ladder is tested in the same way if provided with steps; if it is a stop, it is tested with a transverse load of 100 kgf on each of the bowstrings.

After removing the load, the product is carefully inspected. Deformations, cracks, loosening of movable joints should not appear.

Typically, the test procedure for ladders and stepladders involves the use of a special stand and / or a dynamometer to monitor the load level. However, in some cases, you can get by with a load of the appropriate mass. The main test condition is the absence of people under the load and the tested structure.

Registration

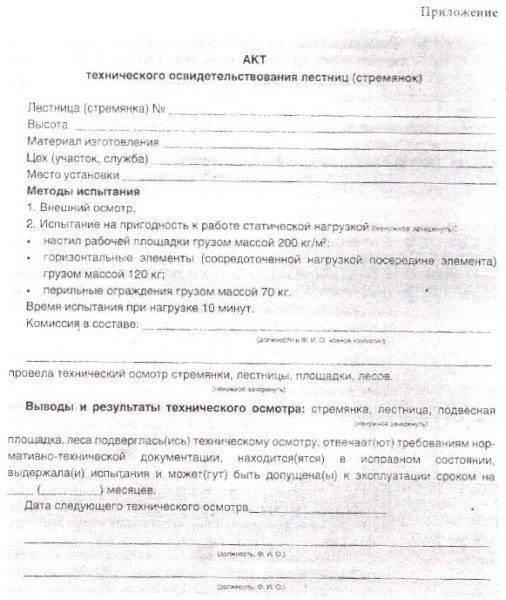

Based on the results of the inspection and testing, an act is drawn up, which usually indicates:

- List of members of the commission with an indication of their positions.

- A full description of the content and order of the work performed: inspection, force applied during each stage of testing, a list of points and directions of its application.

- Stock numbers and their declared conformity to tests.

- List of detected defects or indication of their absence.

- List of products that have successfully passed the test, indicating their inventory numbers.

- A list of those stepladders and ladders to which claims have arisen, with recommendations regarding their further fate (repair or disposal).

An important point: next to the inventory number on the bowstrings of the tested products, the date of the next test is indicated.

Output

Let's hope that the information offered to the reader will be useful. In the video presented in this article, you can explore additional information on the topic discussed.

Good luck in job!